What prize do you get for not moving a single muscle all week? A trophy!

Alternatively, patients who have undergone volumetric muscle loss injuries may be interested in a novel technology recently reported in Advanced Healthcare Materials. The authors of the article – from the University of Nebraska, the University of Connecticut and Brigham and Women’s Hospital – developed a handheld printer to deliver hydrogel-based bioinks for treatment of such injuries.

When a large proportion of a muscle’s mass is lost, due to trauma, disease or surgery, the muscle begins to repair itself in such a manner that disabling scar tissue left behind causes loss of some degree of muscle function. Numerous approaches to assist the body’s natural regenerative processes have been developed, but all have limited efficacy and utility. For example, treatments such as direct cell delivery are constrained by the complex process of differentiating and harvesting myogenic cells, the cells that evolve into skeletal muscle. In settings where a direct and rapid response to volumetric muscle injuries is required – specifically in military trauma care – such approaches are inapplicable.

This latest study demonstrates a feasible approach for treating such injuries. The researchers developed a novel “Muscle Ink” for printing directly into large muscle-loss wounds. Within this specialized ink, vascular endothelial growth factor – key to inducing the angiogenesis and vascularization needed for muscular regeneration – is attached to 2D nanoclay discs, allowing for its continuous release over multiple weeks. The team incorporated these growth factor-bound discs into a biocompatible hydrogel that can adhere to wet tissue, such as the remaining musculature. The resulting scaffold has mechanical properties conducive to cellular regeneration and natural deformation during movement.

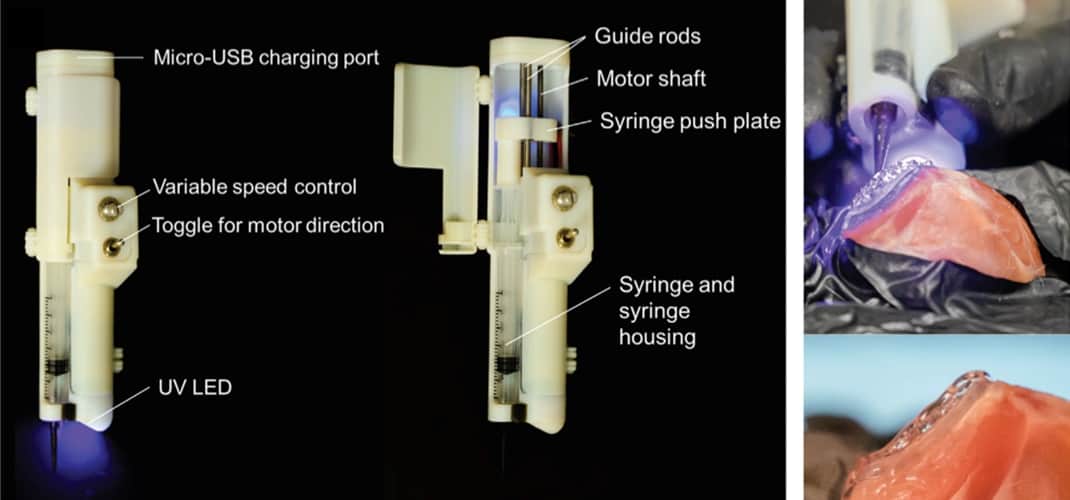

The gel is applied by loading it into a novel handheld printer, composed of a loadable syringe, a motor-controlled syringe pump and an ultraviolet light-emitting diode for in vivo hydrogel crosslinking. Clinicians can utilize the device for hot glue gun-like printing directly into wounds, creating a scaffold for cell regeneration and an environment that induces the same.

The researchers evaluated the efficacy of the printing process in murine models. Animals underwent muscle mass injuries to the quadriceps. Some were left untreated, while others were treated with the Muscle Ink, with or without growth factor. After an eight-week recovery, the animals were tested for running function.

The mice treated with growth factor-loaded Muscle Ink had a maximum running speed insignificantly different from that of uninjured mice. This group was also able to run approximately twice as far as the untreated group or those with Muscle Ink but without growth factor. This test supports the premise that slow release of growth factor by the ink was responsible for the improvement in functional performance after volumetric loss muscle injury.

The research team envisions that, in addition to the tested skeletal muscle, this printing technique could be applied for treatment of other soft-tissue wounds. The handheld printer helps broaden the potential of in vivo delivery of hydrogel scaffolds for tissue therapy.