The long-term supply of key elements in many hi-tech devices is under threat, but is there really a disaster on the horizon? Richard Stevenson investigates

Quiet nights in are better than ever. The move from cathode-ray tubes to flat screens has given us TVs that are slimmer and bigger, with a far clearer picture. We have a much greater choice of what to watch, too. No longer restricted to whatever’s showing on four or five terrestrial channels, we can pick from hundreds or even thousands of programmes thanks to Internet streaming services such as Netflix. And if we are not fully engrossed in what we are watching, we can always keep an eye on the news and communicate with friends by tapping away on our smartphones.

All these benefits, however, depend on chemical elements that rarely, if ever, get a look-in on the nightly news or high-profile documentaries. One such element is indium, which is alloyed with tin and oxygen to form the transparent, conductive oxide that coats the screens of TVs, mobiles and laptops. Indium is also used in infrared lasers, which transmit data down the optical fibres that enable the Internet. In combination with gallium, it is used to make the LEDs that backlight our screens and illuminate our homes. Gallium is also found in smartphones, in lasers providing facial recognition, and in amplifiers that strengthen the signals sent to base stations. Finally, many of these devices feature integrated circuits containing a very thin layer of hafnium dioxide as an insulator. This layer has superseded silicon dioxide-based insulators, which cannot prevent electrons from leaking out of today’s advanced transistors.

Unfortunately, the long-term availability of all three of these critical elements – gallium, hafnium and indium – is in doubt. The American Chemical Society lists nine elements as facing a “serious threat” to supplies within the next 100 years (the other six are arsenic, germanium, gold, helium, tellurium and zinc). Although some reports of imminent shortages – including a 2014 claim, first reported by the BBC, that indium could run out as early as 2025 – have proven overblown, serious questions remain about future supplies of elements found in smartphones and other hi-tech devices.

At first glance, these questions appear easy to answer. Just find out how much material is out there, divide this figure by the projected consumption per year, and the result will tell you how long the element will last. Unfortunately, this “back of the envelope” approach will not give you the right answer, for three reasons. It fails to consider the processes that generate the material; it assumes that it is financially viable to extract all the material that exists; and it ignores where the deposits are, and how little is known or reported about them.

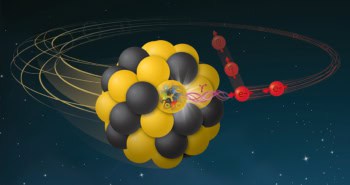

With indium, gallium and hafnium, predicting the future is particularly complex because these elements are not mined directly. Instead, they are by-products. Indium comes from zinc mining; gallium is predominantly extracted from bauxite during alumina refining; and hafnium is found in zirconium deposits. In all three cases, questions about production weigh heavily in discussions of future shortages.

Indium’s volatility

The law of supply and demand suggests that if indium is about to run out, its price should be getting higher. The good news is there is no evidence of this happening over the past decade or so. However, this does not mean that TV, smartphone, lighting and laser manufacturers should breathe a sigh of relief, because a cursory glance at raw price data does not reveal the true drivers of price changes in a small market.

The global production of indium is only about 800 tonnes per year – an amount so small that this soft, silvery metal is not traded on any of the world’s metal exchanges. Because of this, the actions of a single supplier can have a significant impact on price. Between 2002 and 2005, the price of indium rocketed from $100 per tonne to around 10 times that figure due to the closure of a major French refinery coupled with rising demand. More recently, indium’s price fell from around $500 per tonne to $300 per tonne after the Fanya Metal Exchange, a trading platform backed by the Chinese government, collapsed in 2015 amid allegations of large-scale fraud. Max Frenzel, a researcher at Germany’s Helmholtz-Zentrum Dresden-Rossendorf who has studied indium, gallium and germanium supplies, explains that the Fanya failure was significant because the exchange was reported to have amassed a very large stock of indium. The official figure is 3600 tonnes, although Franzel warns that it is hard to know whether this number is realistic. For the figure to be accurate, he notes, the exchange “would have had to amass all the production in the whole of China for more than 10 years”.

Since the Fanya collapse, demand for indium has stagnated, and production has easily fulfilled industry requirements. China and South Korea are each producing about one third of what is needed, with further contributions coming from Canada and Japan. Should production need to increase in future, one relatively easy option would be to increase the proportion of zinc smelters that produce indium. Frenzel estimates that primary zinc production could, if necessary, generate two or three times as much indium as it does today. Upping zinc production would not, however, be an instant solution, as it typically takes between two and five years for a smelter to install new capacity.

An alternative to increasing the production of indium is to recycle and reuse more of it. Most indium is used to make indium tin oxide films for screens, and when these coatings are applied, 90 percent or more of the indium ends up in the sputtering machine itself. This waste material is recycled because doing so makes economic sense for the manufacturer. However, when TVs, laptops and mobiles are thrown away, it’s a different story. As there is so little indium in each of these units, recovering it is not viewed as worthwhile.

Considering levels of recycling, trends in indium demand, and the production of the raw materials that provide its source, Frenzel predicts that in 20 to 30 years the available supply may struggle to satisfy demand. At that point the price will rise, which could lead to additional supplies coming on line. For example, if the price of indium went up by an order of magnitude, some zinc mines could become indium mines.

Gallium over-supply

Gallium is produced on an even smaller scale than indium, with a global total of just 410 tonnes in 2018. The majority of this is used to make lasers, LEDs and radio-frequency power amplifiers.

Like indium, gallium is produced in locations that do not reflect the global distribution of its source materials. Although 95 percent of the global supply of gallium comes from China, Chinese suppliers produce only about half of the world’s refined alumina, the precursor from which most gallium is derived.

Gallium production peaked at 470 tonnes in 2015, leading to an over-supply for the last few years. This surplus is helping to bring down prices that have, for various reasons, been falling steadily for more than 40 years. Adjusting for inflation, gallium prices have plummeted from around $3000 per tonne in the 1970s to just $300 to $400 per tonne today.

Falling prices are one sign that concerns over future supplies of gallium are far less than they are for indium. “We are currently at one-fifth to one-twentieth of [the gallium] we could produce, whereas indium is one-third to half,” explains Frenzel. Even if gallium demand increases, which Frenzel agrees is the long-term trend, he believes it will be at least 40 years before the supply of gallium from alumina and other by-products is unable to satisfy demand. Even if that happens, a rise in gallium prices would enable more production. “For the next fifty years there should not be a problem,” he says.

Mining more hafnium?

Unlike indium or gallium, the world’s hafnium producers are not geared towards consumer goods. Silicon integrated circuits consume only 3-5 percent of annual production. The lion’s share, three-fifths, is used for making superalloys that withstand extremely high temperatures and high pressures. These alloys are deployed in the aerospace industry, featuring in the outer casing of rocket exhausts and in turbine blades. Additional uses of hafnium include plasma cutting tips for welding, nuclear control rods, and catalyst precursors – applications that account for 15 percent, 10 percent and 7 percent of global production, respectively.

The primary source for hafnium is zirconium oxide, which in its raw, mined form always contains about 1.8 percent hafnium. For most users of zirconium oxide, a bit of hafnium makes little difference. For the nuclear industry, however, it is essential that the hafnium be removed to produce pure zirconium. Because of this, makers and users of control rods exert a strong influence over hafnium production levels.

To free hafnium production from this constraint – and establish an alternative to existing, predominantly China-based, producers – a firm called Alkane Resources is trying to establish a new source of hafnium. The Australia-based company hopes to construct a mine in New South Wales and build a processing plant alongside it. According to Alkane’s technical director, Ian Chalmers, the mine could produce between 150 and 200 tonnes of hafnium per year. That is a substantial amount: in 2025, the global market is projected to be 100 to 160 tonnes per year. Alkane’s project has received government approval, and pilot production has taken place at a demonstration plant (see photo). The final hurdle, says Chalmers, is to win investment for a scaled-up facility.

Overall, the available evidence suggests that supplies of indium, gallium and hafnium should hold out for several decades. Beyond that, it’s harder to say – and harder for investors or independent experts like Frenzel to predict.

However, even if these sources do run dry, it may not matter. History attests that when one material is in short supply, alternatives often emerge. In the 1970s, for example, wars in Zaire disrupted the mining of cobalt, which was an essential ingredient in the first permanent magnets. Afterwards, rare-earth magnets came in to replace them. Similarly, efforts are already underway to find alternatives to indium’s conductive oxide, with silver nanowires, silver nanospheres, metal meshes, polymers and allotropes of carbon all showing promise. It is therefore hard to imagine a scenario where technology takes a long-term step backward due to shortages of certain elements. So if you enjoy a good night in, relax: your future viewing experiences may be even better than today’s.