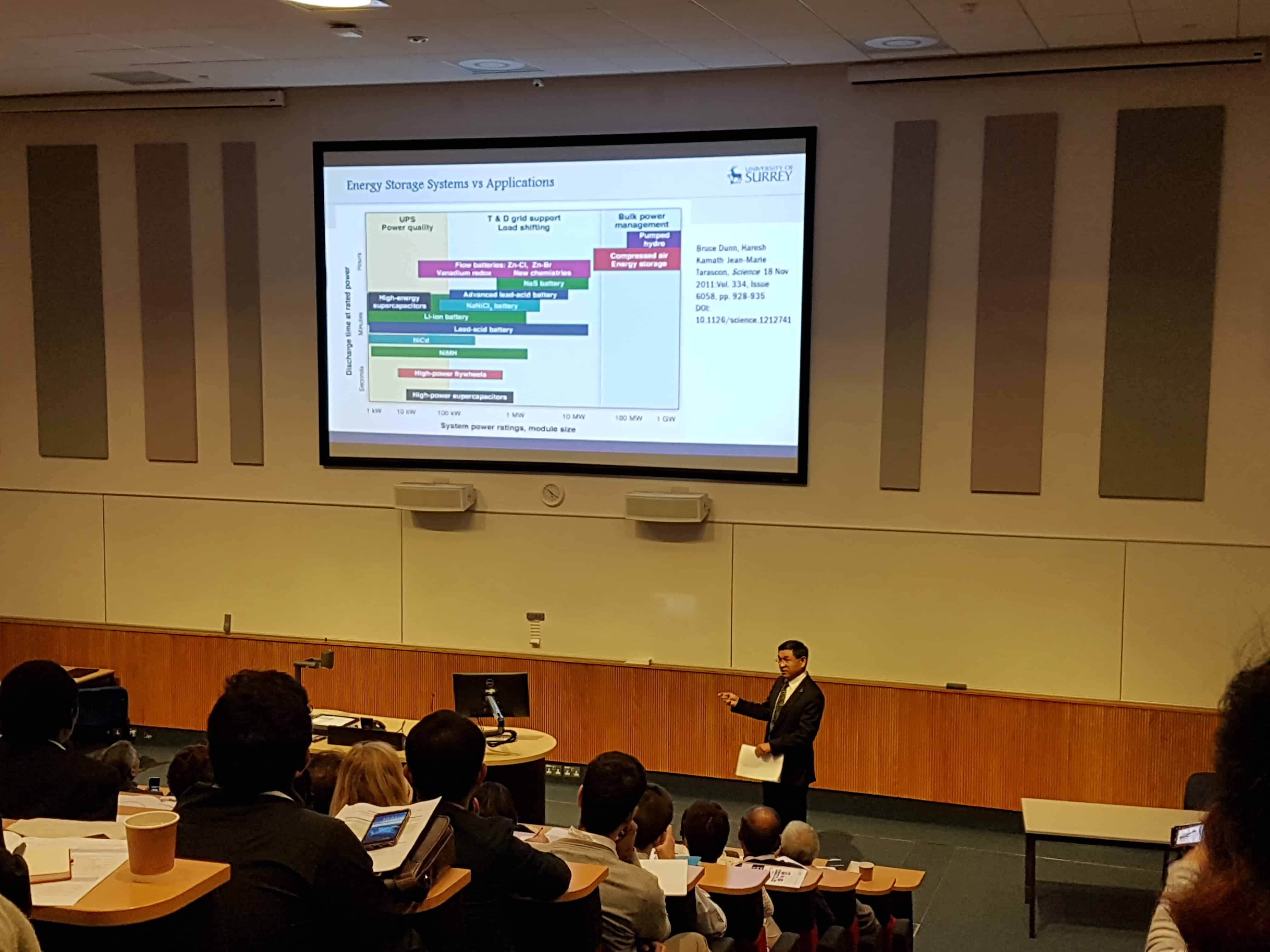

One of the conveniences that makes fossil fuels hard to phase out is the relative ease of storing them, something that many of the talks at Advanced Energy Materials 2018 aimed to tackle as they laid out some of the advances in alternatives for energy storage

“Energy is the biggest business in the world,” Max Lu, president and vice-chancellor of the University of Surrey, told attendees of Advanced Energy Materials 2018 at Surrey University earlier this month. But as Lu, who has held numerous positions on senior academic boards and government councils, pointed out, the shear scale of the business means it takes time for one technology to replace another. “Even if solar power were now cheaper than fossil fuel, it would be another 30 years before it replaced fossil fuel,” said Lu. And for any alternative technology to replace fossil fuels, some means of storing it is crucial.

Batteries beyond lithium ion cells

Lithium ion batteries have become ubiquitous for powering small portable devices, but as Daniel ShuPing Lau, professor and head at Hong Kong Polytechnic University, and director of the University Research Facility in Materials pointed out, lithium is rare and high-cost, prompting the search for alternatives. He described work on sodium ion batteries, where one of the key challenges has been the MnO2 electrode commonly used, which is prone to acid attack and disproportionation redox reactions. Lau described work by his group and colleagues to get around the electrode stability issues using environmentally friendly K-birnessite MnO2 (K0.3MnO2) nanosheets, which they can inkjet print on paper as well as steel. Their sodium ion batteries challenge the state of the art for energy storage devices with a working voltage of 2.5 V, maximum energy and power densities of 587 W h kgcathode−1 and 75 kW kgcathode−1, respectively, and a 99.5% capacity retention for 500 cycles at 1 A g−1.

Metal air batteries are another alternative to lithium-ion batteries, and Tan Wai Kan from Toyohashi University of Technology in Japan described the potential of using a carbon paper decorated with Fe2O3 nanoparticles in a metal air battery. They increase the surface area of the electrode with a mesh structure to improve the efficiency, while using solid electrolyte KOHZrO2 instead of a liquid helped mitigate against the stability risks of hydrogen evolution for greater reliability and efficiency.

A winning write off for pseudosupercapacitors

Other challenges aside, when it comes to stability, supercapacitors leave most batteries far behind. Because there is no mass movement, just charge, they tend to stay stable for not just hundreds but hundreds of thousands of cycles and they are already in use in the Shanghai bus system and the emergency doors on some aircraft as Robert Slade emeritus professor of inorganic and materials chemistry at the University of Surrey pointed out.

He described work on “pseudocapacitance”, a term popularised in the 1980s and 1990s to describe a charge storage process that is by nature faradaic – that is, charge transport through redox processes – but where aspects of the behaviour are capacitive. MnO2 is well known to impart pseudocapacitance in alkaline solutions but Slade and his colleagues focused on MoO3. Although MnO3 is a lousy conductor, it accepts protons in acids to form HMoO, and exploiting the additional surface area of nanostructures further helps give access to the pseudocapacitance, so that the team were able to demonstrate a charge-discharge rate of 20 A g-1 for over 10,000 cycles, which is competitive with MnO2 alkaline systems. “So don’t write off materials that other people have written off, such as MoO3, because a bit of “chemical trickery” can make them useful,” he concluded.

Down but not out for solid oxide fuel cells

But do we gain from the proliferation of so many different alternatives to fossil fuels? According to John Zhu, professor in the School of Chemical Engineering at the University of Queensland in Australia, yes. “For clean energy we need more than one solution,” was his response when queried on the point after his talk. In particular he had a number of virtues to espouse with respect to solid oxide fuel cells (SOFCs), which had been the topic of his own presentation. Besides the advantage of potential 24-7 operation, SOFCs generate the energy they store. As Zhu pointed out, “With a battery energy the source may still be dirty – so you are just moving the pollution from a high population density area to a low one.”

In contrast, an SOFC plant generates electricity directly from oxidizing a fuel, while at the same time it halves the CO2 emission of a coal-based counterpart, and achieves an efficiency of more than 60%. If combined with hot water generation more than 80% efficiency is possible, which is double the efficiency of a conventional coal plant. All this is achieved with cheap materials as no noble metals are needed.

Too good to be true? It seemed so at one point as promising corporate ventures plummeted, one example being Ceramic Fuel Cells Ltd, which was formed in 1992 by the Commonwealth Scientific and Industrial Research Organisation (CSIRO) and a consortium of energy and industrial companies. After becoming ASX listed in 2004, and opening production facilities in Australia and Germany, it eventually filed voluntary bankruptcy in 2015.

So “Are SOFCs going to die?” asked Zhu. So long as funding is the lifeline of research apparently not, with the field continuing to attract investment from the US Department of Energy – including $6million for Fuel Cell Energy Inc. Share prices for GE Global Research and Bloom Energy have also doubled in the two months since July 2018, but Zhu highlights challenges that remain.

At €25,000 to install a 2 kW system he suggests that cost is not the issue so much as durability. While an SOFC plant’s lifetime should exceed 10 years, most don’t largely due to the high operating temperatures of 800–1000 °C, which lead to thermal degradation and seal failure. Lower operating temperatures would also allow faster start up and the use of cheaper materials. The limiting factor for reducing temperatures is the cathode material, as its resistance is too high in cooler conditions. Possible alternative cathode materials do exist and include – 3D heterostructured electrodes La3NiO4 decorated Ba0.5Sr0.3Ce0.8Fe0.3O3 (BSCF with LN shell).

Photocatalysts all wrapped up

Other routes for energy on demand have looked at water splitting and CO2 reduction. As Lu pointed out in his opening remarks, the success of these approaches hinge on engineering better catalysts, and here Somnath Roy from the Indian Institute of Technology Madras, in India, had some progress to report.

“TiO2 is to catalysis what silicon is to microelectronics,” he told attendees of his talk during the graphene energy materials session. However the photocatalytic activity of TiO2 peaks in the UV, and there have been many efforts to shift this closer to the visible as a result.

Building on previous work with composites of graphene and TiO2 he and his colleagues developed a process to produce well separated (to allow reaction space) TiO2 nanotubes wrapped in graphene. Although they did not notice a wavelength shift in the peak catalytic activity to the visible due to the graphene, the catalysis did improve due to the effect on hole and electron transport.

There was no shortage of ideas at AEM 2018, but as Lu told attendees, “Ultimately uptake does not depend on the best technology but the best return on investment.” Speaking to Physics World he added, “The route to market for any energy materials will require systematic assessment of the technical advantages, market demand and a number of iterations of property-performance-system optimization, and open innovation and collaboration are the name of the game for successful translation of materials to product or processes.”

Whatever technologies do eventually stick, time is of the essence. Most estimates place the tipping point for catastrophic global warming at 2050. Allowing 30 years for the infrastructure overhaul that could allow alternative energies to totally replace fossil fuels leaves little more than a year for those technologies to pitch “the best return on investment”. Little wonder advanced energy materials research is teaming.