Surgical tissue adhesives, biomaterials capable of “gluing” tissues such as skin wounds, are the subject of much research effort. Such adhesives work by forming crosslinks (stable chemical bonds) between the proteins of the tissue. Many of the new strategies to develop tissue adhesives try to imitate the crosslinks that mussels employ in nature to attach to surfaces. However, the current chemical approaches in surgical glues that mimic mussel crosslinks still present major drawbacks, such as inflammation or toxicity.

One strategy to overcome these limitations is the use of enzymes produced by mussels to create such crosslinks; but their purification and use also present several complications. To address these issues, Nathaniel Hwang and Byung-Gee Kim, together with their group at the Seoul National University, have developed a system to produce hyaluronic acid and gelatin gel crosslinked with tyrosinase, an enzyme implicated in the formation of mussel adhesions. Here, however, the tyrosinase was produced in genetically modified bacteria. With this novel technology, the researchers were able to develop a tissue adhesive system that is sprayable and injectable (Biomaterials doi: 10.1016/j.biomaterials.2018.04.057).

Fabricating tyrosinase-loaded systems

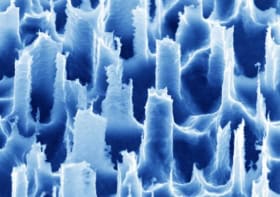

The team’s first task was to produce and characterize the enzyme. To this end, the researchers developed two genetically modified bacteria cell strains (Streptomyces avermitilis and Bacillus megaterium) to produce two different types of tyrosinase. They purified the enzymes and then compared them to a third commercial tyrosinase derived from mushroom. The tyrosinase from the modified bacteria Streptomyces avermitilis presented the highest activity (acceleration of chemical reactions). This only happened in the presence of hyaluronic acid or gelatin, which the researchers related to a better “docking” of the reactive molecule in the enzyme. In addition, the hyaluronic acid-gelatin hydrogels containing tyrosinase did not cause any harm to cells in vitro, overcoming the cytotoxicity limitation.

Secondly, the researchers fabricated hyaluronic acid and gelatin hydrogels with both tyrosinases. Again, the tyrosinase from Streptomyces avermitilis was the fastest at forming the gels, and had the most favourable mechanical properties, confirming previous observations. This capability to create fast (50 s) and stable crosslinks is an attractive feature in a surgical adhesive. Furthermore, these properties can be tuned as desired by adjusting the quantity of hyaluronic acid or gelatin.

Good enough to “glue” tissues?

Once the researchers had proved the efficiency of the enzyme at creating crosslinks, they tested how it performed as a tissue adhesive. During mechanical tests, the hyaluronic acid and gelatin hydrogel glued mouse skin much better (adhering for a longer time and enabling greater stretching) and showed impressive results when compared with studies employing other tissue adhesives.

To create an injectable system, they added salt to the hydrogel to reduce its viscosity. The hydrogel recovered its properties after injection into a liquid environment, due to diffusion of the salt. Furthermore, when injected under the skin of mice, the engineered hydrogel caused no inflammation. After 28 days, it was fully resorbed and replaced with host tissue. Moreover, it was also able to recruit cells. These results suggest a positive effect of the adhesive hydrogel in the healing of wounds.

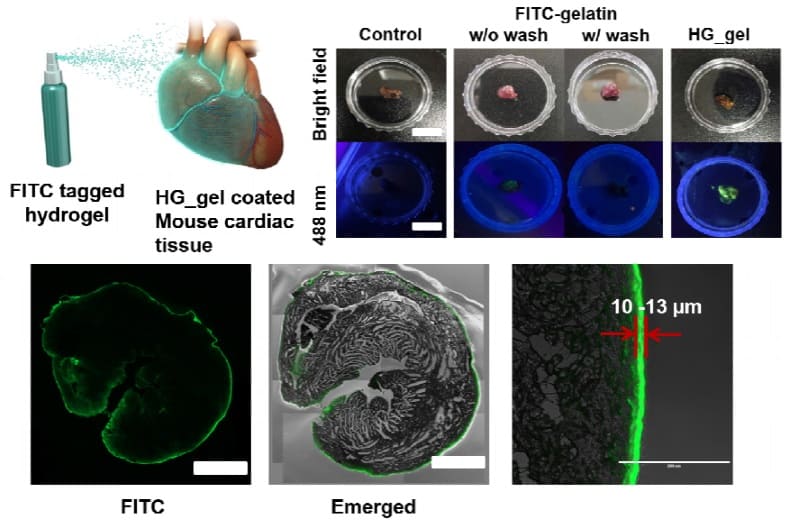

As a proof-of-concept, the researchers also developed a sprayable aerosol system employing the same solution as for the injection. The system effectively coated glass surfaces and recovered its properties in wet conditions, as seen in the injectable system. Taking a step further, they showed that the aerosol could coat a mouse heart, creating a stable film.

A potential new surgical tool

The authors have developed a tissue adhesive based on a novel enzymatic crosslinking system. The technology can be employed as a sprayable or injection-based system, which provides even more potential for further applications. In addition, due to its good compatibility with cells and after injection, the adhesive also shows potential as a system to carry and deliver cells for cell therapy strategies. All of these properties show promise for creating a future surgical tool for tissue engineering and regenerative medicine.