The prospect of commercially viable, fusion-power plants based on the spherical tokamak has moved closer after a major experiment in the UK released its first results. Using a novel kind of exhaust, researchers at the Mega Amp Spherical Tokamak (MAST-U) at the Culham Centre for Fusion Energy in Oxfordshire were able to cut the waste heat load on the reactor walls ten-fold. If the results can be extrapolated to working fusion reactors, then exhaust material and other components would not need to be regularly changed – making such reactors more cost effective by allowing them to operational for longer.

Operated by the United Kingdom Atomic Energy Authority (UKAEA), the CCFE is already home to the Joint European Torus (JET) tokamak, which was built in 1983. MAST, however, is different to JET in that it features a spherical, cored-apple like plasma. JET, in contrast, has a doughnut-shaped device, as does the giant ITER experiment, which is currently being built in Cadarache, France.

This result shows so much promise for compact designs

Ian Chapman

Built in 1999, MAST has been used to confine highly pressurized plasmas with a lower magnetic field than those used in JET, which could help to build a more cost-effective fusion device. The plasma in MAST is created by letting in a small puff of deuterium gas, which is then heated by driving a current through it. This flow of charged particles around the tokamak’s wall starts off the plasma and gives it its initial heat. Magnetic fields then confine the hot plasma of deuterium and keep it away from the walls of the tokamak.

Following over a decade of research, in 2013 MAST underwent a major £55m overhaul – dubbed MAST-U – that involved the device being completely stripped and rebuilt. The upgrade, funded by the Engineering and Physical Sciences Research Council, involved new power supplies, upgraded heating systems and diagnostic tools to help scientists not only study plasma conditions relevant to ITER, but also plan what kind of facility will be needed next to deliver the goal of providing fusion power to the grid.

Turning a corner

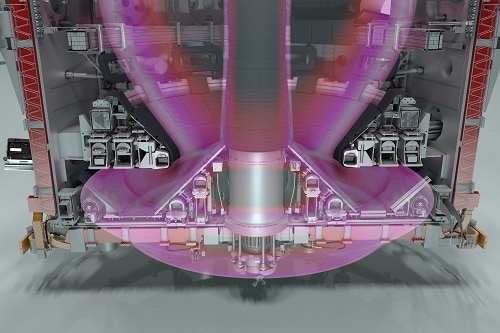

One of the biggest aspects of the upgrade involved installing a new kind of heat exhaust system known as a divertor. The fact that spherical tokamaks are more efficient than their doughnut-shaped counterparts, with more power for a smaller volume, has its downsides. In particular, the waste heat from the plasma is more intense and it is through the divertor that this power must be funnelled.

In a spherical tokamak reactor, the exhaust carries a fifth of the energy of the fusion reaction. A standard divertor of the kind used at JET and ITER, which is like a bowl at the bottom of the reactor vessel, would not be good enough for a spherical tokamak scaled up to fusion-like conditions. Also, the heat load – running at tens of megawatts per square metre – would simply be too much to withstand and quickly degrade the material.

Researchers at Culham therefore built a new kind of divertor called “Super-X”. Tiled with graphite, Super-X is shaped like a funnel, with the idea being that the plasma load is spread over a larger area as it exits the tokamak. Simulations have shown that the Super-X divertor could decrease the heat flux and plasma temperature in the divertor — taking a 50 MW/m2 heat load and reducing it to just 5 MW/m2.

MAST-U was completed in late 2019 and a year later achieved its first plasma of deuterium. Since then engineers and scientists have been conducting tests and have now confirmed what their simulations had shown – that the Super-X divertor can reduce the exhaust heat load ten-fold.

“This result shows so much promise for compact designs,” says Ian Chapman, UKAEA chief executive. “This means that materials in fusion plants will last a lot longer before needing to be replaced, which is crucial for a commercial reactor.” According to Andrew Kirk, MAST-U lead scientist, the result indicates that the divertor wall would only need to be replaced once during a power plant’s lifetime. UK announces £220m to design a ‘commercially viable’ fusion power plant

Research on MAST is informing the conceptual design of the UK’s prototype fusion power plant – Spherical Tokamak for Energy Production (STEP). Work on the £220m design is set to be complete by 2024 with the aim to build STEP by 2040. Chapman confirms that STEP will feature a Super-X divertor configuration and engineers will now spend the coming months on MAST-U studying how to minimize the heat around the divertor while trying to maximise the fusion performance of the plasma.