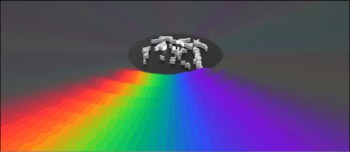

Leaf-like devices that are light enough to float on water could be used to generate fuel from solar farms located on open water sources – an avenue that hasn’t been explored before, according to the researchers from the University of Cambridge in the UK who developed them. The new devices are made from thin, flexible substrates and perovskite-based light absorbing layers, and tests showed that they can produce either hydrogen or syngas (a mixture of hydrogen and carbon monoxide) while floating on the River Cam.

Artificial leaves like these are a type of photoelectrochemical cell (PEC) that transforms sunlight into electrical energy or fuel by mimicking some aspects of photosynthesis, such as splitting water into its constituent oxygen and hydrogen. This is different from conventional photovoltaic cells, which convert light directly into electricity.

Because PEC artificial leaves contain both light harvesting and catalysis components in one compact device, they could in principle be used to produce fuel from sunlight cheaply and simply. The problem is that current techniques for making them can’t be scaled up. What is more, they are often composed of fragile and heavy bulk materials, which limits their use.

In 2019 a team of researchers led by Erwin Reisner developed an artificial leaf that produced syngas from sunlight, carbon dioxide and water. This device contained two light absorbers and catalysts, but it also incorporated a thick glass substrate and coatings to protect against moisture, which made it cumbersome.

New, lightweight version

To make the new, lighter version, Reisner and colleagues had to overcome several challenges. The first was to integrate light absorbers and catalysts into substrates that are resistant to water infiltration. To do this, they chose a thin-film metal oxide, bismuth vanadate (BiVO4), and photoactive semiconductors known as lead halide perovskites, which can be coated onto flexible plastic and metal foils. They then covered the devices with micron-thick water-repellent polyethylene terephthalate. The result was a structure that works and looks like a real leaf.

“We placed the light absorbers at the centre of the devices, to shield them from water,” explains Reisner. “The moisture-sensitive perovskite in particular needs to be completely isolated.”

The catalysts are deposited on both sides of the device. The perovskites and BiVO4 harvest solar radiation, but instead of producing electricity like a photovoltaic panel, they use the harvested energy to power a chemical reaction with the support of the catalysts. “This allows us to essentially drive chemistry on a solar panel – in our case, converting the greenhouse gas carbon dioxide with water to produce syngas, an important industrial energy carrier,” Reisner tells Physics World.

The researchers tested their leaves floating on the River Cam in Cambridge and found they convert sunlight into fuels as efficiently as natural plant leaves. Indeed, a device containing a platinum catalyst achieved an activity of 4,266 μmol H2 g−1 h−1.

Farms for fuel synthesis

“Solar farms have become popular for electricity production; we envision similar farms for fuel synthesis,” says team member Virgil Andrei. “These could supply coastal settlements, remote islands, cover industrial ponds, or avoid water evaporation from irrigation canals.”

Liquid flow is steered on surface inspired by conifer leaves

“Many renewable energy technologies, including solar fuel technologies, can take up large amounts of space on land, so moving production to open water would mean that clean energy and land use aren’t competing with one another,” Reisner adds. “In theory, you could roll up these devices and put them almost anywhere, in almost any country, which would also help with energy security.”

The researchers say they will now work on scaling up and improving the efficiency and stability of their devices. “Our team is also studying new catalysts to widen the chemistry scope of artificial leaves to allow us to make other products from abundant feedstocks and ideally, in the long term, many different chemicals on demand,” Reisner says.

The present study is detailed in Nature.