Blood may be thicker than water, but in a narrow enough tube, both liquids flow like treacle. This sluggish behaviour arises because, as you reduce the size of the channel, friction between the liquid and the channel wall comes to dominate the flow dynamics. Researchers have tried various ways of engineering surfaces to reduce this effect, but now a team from France, Switzerland and Ireland has gone a step further by doing away with solid channel walls altogether. Instead, the researchers confine their fluid within a conduit that itself consists of a liquid.

Writing in Nature, Peter Dunne (University of Strasbourg), Takuji Adachi (University of Strasbourg and University of Geneva) and colleagues describe how they form the walls of their conduit using ferrofluid – a colloidal suspension of magnetic nanoparticles in oil.

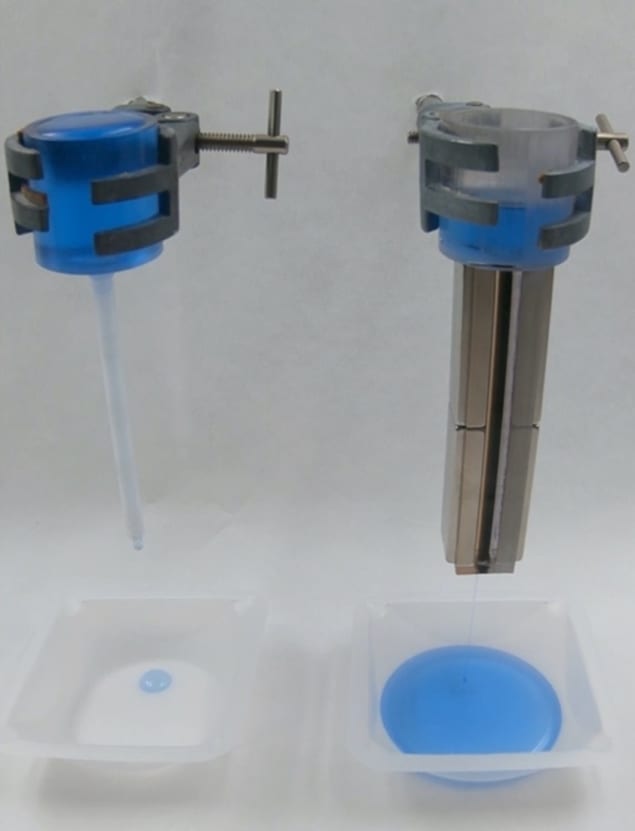

The researchers outlined the shape of their desired channel using long, rod-shaped neodymium magnets held in a 3D-printed framework. With four such magnets arranged with alternating polarities around the channel, they created a quadrupolar magnetic field whose strength fell to zero at the centre. This meant that the ferrofluid stuck to the inner edges of the framework, while the water that they channelled was confined to a narrow stream at the conduit’s centre.

By varying the properties of the ferrofluid and the distance between the magnets, the researchers created water “antitubes” approximately 14 µm across. They calculated that the right combination of parameters could yield antitubes thinner than 1 µm, though this was beyond the detection limit of the team’s equipment.

The ease with which a fluid flows over a surface is described by the slip length. In fluids that interact with the channel wall, flow is fastest at the centre and decreases along an approximately parabolic trend towards the solid–liquid interface. The slip length defines the distance beyond this interface at which the flow velocity would fall to zero. A fluid that is held stationary at the channel edge has a slip length of zero, while longer slip lengths indicate more freely flowing fluids.

That, at least, is the case when the sides of the channel are solid and immovable. In the experiments reported by Dunne and Adachi, the magnetic fluid making up the conduit walls moves too, flowing along with the water near the centre of the channel, and recirculating back to the start along the outside edge, next to the magnets. This results in an effective slip length much longer than could be achieved if the conduit walls were static.

“What is amazing is that we get a slip length of millimetres, whereas normally this is measured in nanometres or micrometres,” says study co-author Thomas Hermans, of the University of Strasbourg.

Magnetic control

While this very-low-friction fluid conduit was achieved with a static arrangement of magnets, the researchers found that they could manipulate the flow by altering the magnetic field configuration. Bringing an external magnet near to the conduit, for example, severed the water antitube, stopping its flow and functioning as a magnetic valve. When the external magnet was removed, the antitube repaired itself and the flow of water resumed.

The team used a similar effect to create a “magnetostaltic” pump, which they call the Qpump. In this device, concentric rings of magnets define a circular conduit, except that the water antitube is periodically disrupted by magnetic polarity reversals along the length of the inner ring. When the inner ring rotates, these localized blockages move along the channel’s circumference, driving water as they go.

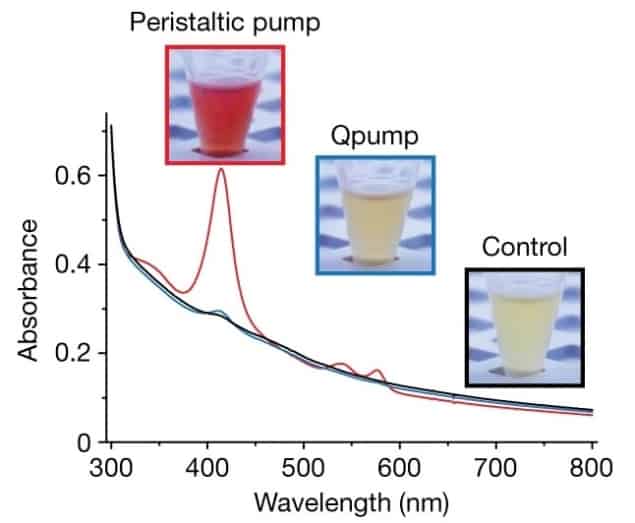

When they tested the Qpump with blood instead of water in the central channel, Dunne and colleagues found it to be a much gentler way to drive fluid flow than conventional peristaltic pumps. Peristaltic pumps work by squeezing the walls of the conduit, but this induces shear forces that can rupture blood cells. The Qpump avoids such forces, meaning it could be used to drive a heart–lung machine, for example, without damaging the blood in the process. First, though, the team intends to prove the principle by applying it outside of the clinic.

“Our start-up company, Qfluidics, just entered the Merck global accelerator programme, where we will see if Qpumps can be used to pump delicate biologicals other than blood,” says Hermans. “The regulations for such uses are very much reduced as compared to medical applications, so this will be the first real application we will pursue.”