The coffee ring effect can be suppressed in 2D-crystal ink droplets by using a specific mixture of alcohols as a solvent. That is the conclusion of an international research team led by Tawfique Hasan at the University of Cambridge. It has found that Marangoni flow in the drying droplets suppresses the capillary flow that creates rings. The study could lead to better techniques for printing nanoparticles onto substrates for the manufacture of electronic and photonic devices.

Nanoparticles and 2D nanocrystals such as graphene have unique electronic and optical properties that can be very useful for creating new technologies. The tiny particles can be suspended in a solvent and the mixture used as an ink to pattern a substrate to create a device. However, this process is hindered by the coffee ring effect – which is also responsible for the dark ring at the edge of a dried coffee stain. This ring forms because the outer edge of a coffee droplet dries faster than the interior. This drives a capillary flow of liquid and coffee particles from the centre of the droplet to the edge. Once the liquid has evaporated, a concentrated ring of coffee particles is left behind.

This effect can be suppressed in 2D crystal printing using material additives, but these introduce irregularities that limit the electrical performance, scalability, and reproducibility of devices. In previous research, Hasan’s team discovered that the coffee ring effect can be inhibited by using specific mixtures of alcohols as ink solvents. In droplets containing black phosphorous flakes they found that these mixtures could induce Marangoni flows, which are driven by gradients in surface tension.

Alcohol cocktail

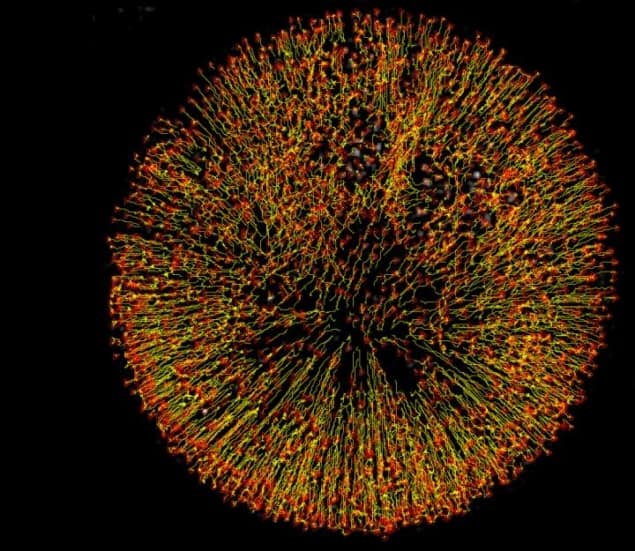

In their latest research, the researchers explored the drying mechanisms of the process in more detail using several different types of flakes including graphene. Through a series of experiments, they determined how the uniformity of crystal depositions varied between inkjet-printed droplets with different alcohol mixtures. Using high-speed micro-photography to map out the trajectories of the suspended particles, they discovered that a high degree of uniformity could be achieved through inks containing a certain mixture of isopropyl alcohol and 2-butanol.

Physicists upend conventional wisdom of how paint dries

As they dried, Marangoni flows in these droplets prevented the droplet contact lines from pinning to the surface, allowing the droplets to spread out over larger areas. This action suppressed the capillary flows that cause the coffee ring effect, allowing crystal flakes to be evenly deposited across the glass substrate as the droplets dry. Hasan’s team could print micron-scale arrays of 4500 nearly identical devices onto both silicon wafer and plastic substrates. They also demonstrated a near indistinguishable performance in the devices as gas sensors and photodetectors.

The technique could be used to create inexpensive electronic and photonic devices, as well as catalysts, solar cells, batteries, and functional coatings.

The research is described in Science Advances.