Radio frequency identification (RFID) chips can be used to keep track of human organoids, according to new experiments by researchers in the US and Japan. Combining organoids (which are samples of human tissue grown from stem cells that mimic organs) with digital technology in this way could prove useful for advancing drug testing and monitoring transplant patients.

RFID is a cost-effective technology that is widely used in applications as diverse as train and bus passes, toll-collection on highways, livestock tracking and clothing tags to deter shoplifters. In 2017, the world RFID market was estimated to be worth US$11.2 billion and it is expected to grow by 10% annually.

In recent years, researchers have been looking to employ RFID in healthcare. Medical applications now include an oral “digital pill” to monitor some chronic conditions. This device emits radio frequency signals that can be sent to a smartphone or other device in real time, thus providing important data to help a patient take the appropriate medications at the right moment.

Embedded RFID chips

A team led by Takanori Takebe of the Cincinnati Children’s Hospital Medical Center, Tokyo Medical and Dental University and Yokohama City University has now done something completely different and has embedded RFID chips into human organoids for the first time.

Organoids can be thought of organs in miniature. They are increasingly being employed in biomedical research for studying diseases since they have the same structure, function and phenotype as human organs. This is because they are grown from induced pluripotent stem cells (iPSCs), so they divide, differentiate and self-assemble in the same way as the iPSCs themselves. As such, they can be used to test the effects that certain drugs have on our organs in ways that more traditional cell cultures can’t.

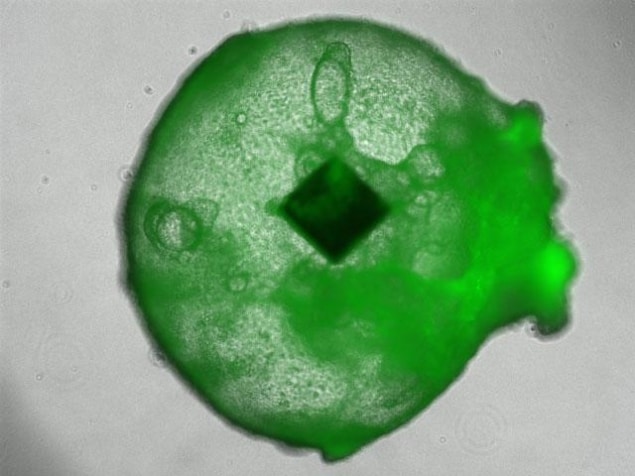

The researchers introduced RFID chips into organoids by taking advantage of natural cavitation processes that take place when organoids self-assemble into 3D structures during growth. “In this way, we succeeded in introducing the RFID microchips without disturbing the organoids,” says Takebe. “We did this by mixing the chips with a cell culture inside a gel.”

Technique tested on liver organoids

The team tested out its technique on liver organoids containing commercially available RFID chips 0.4 mm in size. The organoids were grown from 10 different iPSC lines from both healthy and diseased donors.

“We found that 95% of the 96 test organoids successfully incorporated the chips,” says Takebe. “The organoids were undamaged by the procedure and were shaped normally, secreted normal liver proteins and transported bile as expected.

“Surprisingly, there were almost no differences between organoids containing a chip and those without,” he tells Physics World.

The researchers used the RFID chips to measure lipid accumulation in organoids grown from healthy iPSCs and those grown from iPSCs taken from patients with fatty liver disease. They were able to distinguish between both groups in their experiments.

RFID chips are robust

“Although we have only introduced RFID microchips into organoids so far, I imagine that we could also embed other types of micro-devices using our technique,” says Takebe. “In this way, we could potentially sense, record and track different types of behaviour in live organoids. This would open new avenues in drug testing, advanced biological studies and even post-transplant tracking.”

RFID chips are known to be robust and, not surprisingly, they remained so in the organoids tested. For instance, they continued to function normally after being frozen to temperatures of nearly -200°C and then thawed, embedded in paraffin and at a range of different pHs. “These are all the types of conditions they might need to survive in to be useful in research,” explains Takebe.

The researchers, reporting their work in iScience 10.1016/j.isci.2018.05.007, say that they will now try to produce the hybrid organoids on a larger scale. “We are working on integrating a high-speed printer to do this. We are also looking to develop a system that can scan organoid radio frequency and fluorescence signals at the same time for real-time monitoring of the structures.”