By Tushna Commissariat in Baltimore, Maryland, US

Metamaterials are always a hot topic at the APS March meetings, and this afternoon we were treated to an array of the latest developments in the field. Just in case you have not come across the term before, a metamaterial is an artificially crafted material that aims to achieve the naturally unattainable. These materials are engineered to have special physical properties – some metamaterials act as optical or acoustic cloaks, while some can harvest energy or be used to dissipate it in some form.

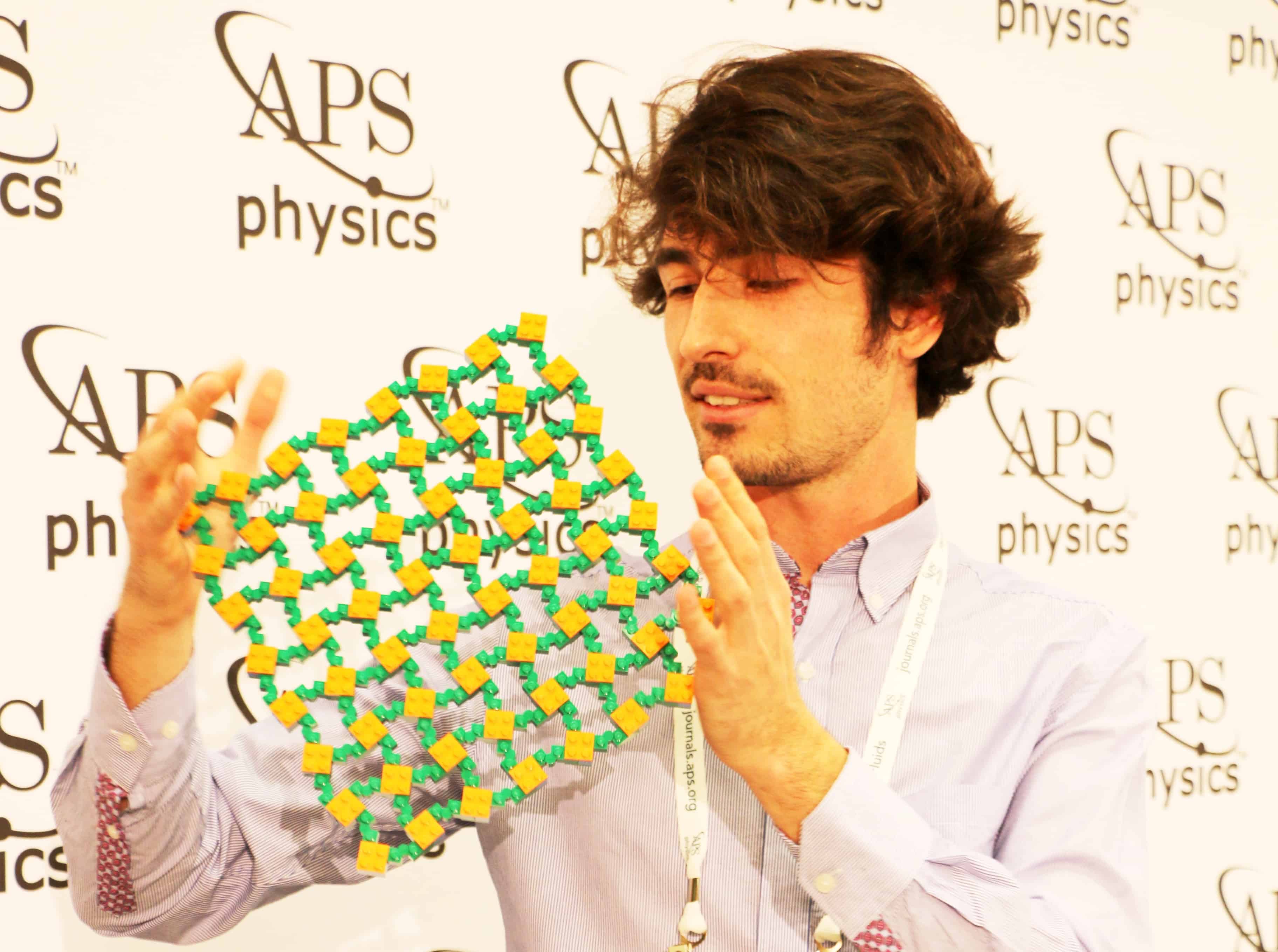

Paolo Celli of the University of Minnesota in the US loved playing with LEGO bricks as a child. Now, the physicist still gets to play with LEGO, as his team has been using the bricks both to understand how metamaterials interact with waves and also as an inexpensive and accessible outreach medium. While the researchers initially looked at 3D printing to develop their platform material, they soon found that LEGO bricks attached to a baseplate made for an agile, versatile, low-cost platform that was not highly damped and could be easily reconfigured.

Celli and colleagues have already used the LEGO to experimentally demonstrate phononic band gaps and the associated energy-trapping mechanisms. They are currently working on demonstrating the control of wavelengths that are larger than the width of waveguides realized in the brick pattern, with potential applications in subwavelength wave focusing and imaging. We will be talking to Celli tomorrow, so watch out for more on LEGO metamaterials soon.

Ahmad Rafsanjani of McGill University in Canada is inspired by the complex geometric patterns found in Islamic art. This isn’t the first time that Islamic art has had an impact on physics – it has previously been used to find quasicrystal patterns. Using some of these detailed motifs, Rafsanjani’s team has fashioned a novel “auxetic” metamaterial – these materials have a negative Poisson’s ratio in that they become thicker perpendicular to the applied force when stretched. The aim was to create a planar metamaterial that could keep its uniform shape while being deformed. The material can snap between two stable states.

Using a laser cutter and a sheet of rubber, Rafsanjani carves out the pattern, which includes small ligaments or joints between any two cuts. The researchers found that different types of cuts and cut profiles produce different geometries, giving them another design parameter that they could play with. The material could be used in flexible and stretchable devices, medical implants, wearable exoskeletons and even in solar panels or satellites as it is cheap and easy to fabricate.

Ahmed Elbanna’s team at the University of Illinois Urbana-Champaign in the US is trying to answer the question “What makes materials tough and robust?”. Motivated by the structure of bone – which has staggered and suspended beams of calcium-phosphate “foam” – the team has now developed new soft composites that deform under tension to create “corrugated” or wavy surfaces. The more the material is stretched, the wavier the channels within it become, thanks to the deformation, and the longer an inclusion, the more bendy the material.

Elbanna points out that while he and his colleagues did not start out with an auxetic material, they too eventually created one with different assemblies of the rigid inclusions within the soft material. The channels close when the stretching stops, though Elbanna could not say how many repeated stretches the material could survive before it failed. The team found that the deformation process is smooth and controllable, and it can lead to materials with tunable wettability, unique filtering capabilities or the ability to absorb specific frequencies of sound.

The team also found that certain bandwidths become forbidden as the material is stretched, meaning that the material could be used in some form of seismic damping. For example, it could be used to damp the low-frequency earthquakes waves that are particularly damaging to high-rise buildings. The researchers are working with experimentalists and environmental agencies to realise their material.