A new technique that identifies defective components in electrical appliances by determining whether they have overheated could help extend the useful life of electronic devices. The technique, developed by researchers at the Friedrich-Alexander-University (FAU) in Erlangen-Nürnberg, Germany, works by monitoring the intensity of light emitted by micron-sized “supraparticles” that are embedded in the appliances and contain heat-sensitive luminescent nanoparticles.

Electronic (or e-) waste is the world’s fastest growing domestic waste stream, notes Jakob Reichstein, a PhD student at FAU and lead author of a new paper on the technique. Repairing complex electrical devices is time consuming and can be expensive. Many devices cannot easily be recycled either, which means that valuable resources end up in landfills.

Red, green and blue-light-emitting particles

Reichstein and colleagues chose to address this problem via so-called “smart” additives. Unlike classical additives, smart additives are not designed to improve the physical properties of a material or product. Instead, Reichstein explains that they add information to it. “The microparticles we have developed allow defective components in electrical appliances to be identified more quickly and easily using light signals,” he says. By making repairs easier, Reichstein adds, the technique “could lead to a paradigm change in how we deal with e-waste”.

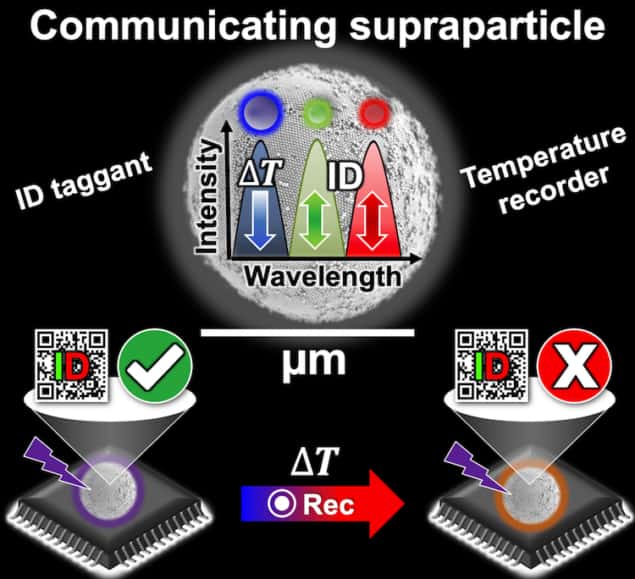

The team made its microparticles from three different types of nanoparticle: one that emits blue light, another green and the third red. They produced these nanoparticles separately using two different wet-chemistry processes, then combined the red and green building blocks using a droplet-evaporation technique similar to the spray-drying process used to produce milk powder. This process forces the nanoparticles together into a raspberry-like structure, and the resulting red-green light-emitting particles make up the core, or signal element, of the finished supraparticles. In the final step, the FAU team encapsulates this signal element with blue-light-emitting organic nanoparticles to create a core-satellite structure.

The three nanoparticles play different roles within the finished supraparticles. While the ratio of the light intensities of the red and green signal elements indicates the particle’s identity, the blue nanoparticles act as thermal history recorders. “If the particle has been exposed to temperature higher than a specific temperature, the blue signal decreases in intensity,” Reichstein explains. “An overheated, and therefore usually damaged, micro-component in a device can therefore be detected by the weaker blue light signals it emits.”

Simple optical readout

Because the identity and temperature sensitivity signals are determined by the structure and quantity ratio of the nanoparticles, it is possible to tailor them to specific electronic devices simply by changing the composition of the supraparticles, Reichstein says. Another advantage of the FAU team’s technique is that the information provided by the smart supraparticle can be read out using a simple optical method.

Opto-refrigerative tweezers prevent trapped particles from overheating

Looking forward, the researchers hope to combine different luminescent indicators into a single supraparticle to record other potentially damaging triggers, such as moisture and temperature, as well as heat. “In the longer term, we plan to fabricate customized smart additives that record all such triggers in a product and therefore allow us to monitor the functional status of an object at any time,” says team leader Karl Mandel. “The mission of our group is to turn materials into intelligent objects and bridge the analogue and digital world via communicating particles.”

The research is detailed in Advanced Materials.