Pushing the limits of silicon electronics to make smaller, faster and more efficient devices is getting harder. One possible way forward is to take advantage of the many phenomenal properties of nanocarbon structures that have been discovered over the past 40 years. However, amongst this suite of carbon nanomaterials there has been a conspicuous lack of wire-like materials with metallic properties that can be reliably customized and produced. This poses a challenge because connecting nanocarbon semiconductor components with the same old copper or silver wires can take the shine off their appeal.

While carbon nanotubes with metallic properties can be made with relative ease, the snag is that a heap of nanotubes with semiconducting properties are inevitably produced at the same time. Unfortunately, separating metallic nanotubes from semiconductor nanotubes en masse remains something of a dark art. Another option is graphene; with the unprecedented mobility of its π-electrons, doping can push graphene’s conductivity well above copper. But if graphene is cut into strips called graphene nanoribbons (GNRs) to make wires for interconnects, the material’s delocalized electrons become confined by the width of the nanoribbon. This opens a bandgap that makes the material a semiconductor or even an insulator.

Now, researchers in the US have shown how to produce graphene nanoribbons with robust metallic properties to order, providing the missing link for all-carbon electronic devices. The work was led by Daniel Rizzo, Gregory Veber and Jingwei Jiang, who are researchers in the labs of Michael Crommie, Felix Fischer and Steven Louie at the University of California, Berkeley.

Synthesis of theory and experiment

“The search for metallic GNRs has been a long-standing question in this field,” says experimental physicist Crommie. Not only is demand high for metallic GNRs, but for quite a while now people have known what is needed to make them. Somehow, nanoribbons must be decorated with features that have an electronic state right in the middle of the bandgap – a so-called zero-mode state. Then, it must be ensured these zero-mode states are effectively equidistant from each other so that electrons can hop with equal ease between these states along the length of the nanoribbon.

“That idea is actually a century old,” says theoretical physicist Louie, adding that pioneers right at the beginning of quantum mechanics were contemplating similar ideas. The catch, as Louie points out, is that this is very hard to do in practice. Just getting the zero-mode state at all is far from trivial, not only to design in the first place but then to synthesize. What often happens is that the states end up paired so that electrons can hop about within each pair much more easily than they can hop to the adjacent pair, making the material a semiconductor. Conversely, when the building blocks are made evenly spaced, there is typically no zero mode.

Despite these challenges, the possibility of producing metallic GNRs retains its allure because of the atomically tailored features of GNRs that can be reliably and selectively produced when stitching GNRs together from specific precursor molecules. This is something that is simply not possible for carbon nanotubes. The hunt was on not just for the right precursors but also the reaction conditions to make them assemble into nanoribbons with equidistant zero mode states.

“Cross your fingers”

“You can’t go in there with a pair of tweezers to guide their assembly,” says chemist Fischer. “Once you put the molecular precursors on the surface and provide the energy they need to form a nanoribbon all you can do is cross your fingers and hope that all the planning and design that went into the structure of the precursor pays off and channels the self-assembly to the one desired GNR.”

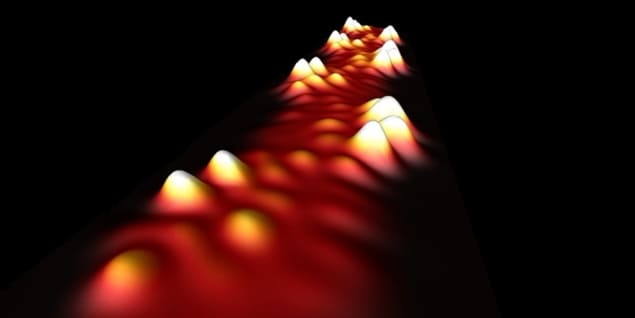

The whole scenario may sound like a parent hopelessly trying to nudge their wayward offspring back onto the straight and narrow, but in this case the group’s collective expertise in materials physics, precursor design and synthetic chemistry paid off. The researchers used a precursor made of linked strips of aromatic rings, which stitch into the graphene nanoribbon backbone, and a methyl group that adds an extra carbon atom along the edge. They then stitched them together head-to-tail on a gold surface to produce nanoribbons where the extra carbon atom resulted in a tiny promontory alongside a sheltered cove of atoms, thus producing equally spaced zero mode states stemming from alternating sides of the nanoribbon. Sure enough, scanning tunnelling spectroscopy maps of the nanoribbons revealed the much hoped for metallic behaviour due to hopping between the zero mode states.

The inbuilt fix

But that is where the plot thickens. When the researchers further explored the properties of their system with ab initio calculations, they realised the underlying gold surface was inducing doping and surface fields that were actually helping to hold together the extremely narrow bandwidth of metallic behaviour in their GNR. Take the gold surface away and a bandgap would open up again.

To get around this, one must remember that the honeycomb structure of carbon atoms in graphene can also be described by two superposed overlapping triangular lattices. This symmetry affects the electron behaviour because mobility along the metallic zero-mode states is confined to one sublattice as opposed to hopping also between two sublattices. However, hopping along just one sublattice is harder because an electron must hop to its second nearest neighbour, and so has further to go.

How to engineer topology in graphene nanoribbons

The problem was easy to fix in theory, as Louie points out, because it involves breaking the symmetry of the sublattices. Achieving this in practice is quite another matter, but fortunately the researchers were able to exploit the tiny cove structures on the edges. Using further chemical reactions to join the carbons on either side of the mouth of these coves they formed five-membered carbon rings, thus directly connecting two sites from one sublattice (something not allowed in regular graphene). This broke the symmetry, increasing the metallicity by a factor of twenty. “We got lucky with our design,” says Fischer. “The fix was built-in essentially.”

Having demonstrated a procedure for producing graphene nanoribbons with a robust broad metallic mode, Crommie is confident that with “all the tricks of organic chemistry,” the process could be improved to make these materials widely available. Possible next steps include creating electronic devices with the nanoribbons to evaluate their performance directly, and exploring their behaviour on different surfaces and in heterostructures.

The research is described in Science.