Using a combination of experiments and analytical thermodynamic modelling, researchers in the US have produced a new tungsten-based nanocrystalline alloy that is stable at temperatures above 1000 °C. Nanocrystalline alloys rarely survive such high temperatures and this breakthrough could lead to the development of new materials that combine great strength with high-impact resistance.

Metals comprising nanocrystalline grains – tiny crystallites measuring just tens of nanometres across – are much stronger than those containing larger micron-sized structures. Unfortunately, these nanocrystalline materials are also more unstable. One problem is that the tiny grains can grow and merge together at high temperatures – something that softens the metal. This is not a welcome phenomenon, given the elevated temperatures routinely employed in metals’ processing. Although researchers have tried to devise methods to prevent such unwanted grain growth, no satisfactory solution has yet been found.

Now a team at the Massachusetts Institute of Technology (MIT) led by Christopher Schuh may have come up with a way. The researchers have designed and fabricated alloys containing nanocrystals that do not coalesce at high temperatures. “Our design method is based on calculating the energies of all the atoms/bonds in a given alloy, including those in crystal environments and those that are located at the grain boundaries, between crystals,” Schuh explains. “We specifically calculate the effects that different alloying elements have on the structure’s energy, and seek to identify which elements can stabilize the grain boundaries and so lead to and maintain the nanocrystalline state.”

Industry has been trying to create alloys with ever-smaller crystalline grains for years now, Schuh says, but nature favours low-energy states, which inevitably means larger crystals.

New blends

Following on from the calculations, the MIT team then successfully synthesized the alloys that it had designed using suitable combinations of different metals in predefined proportions. The researchers also looked at metal blends that are not usually found together and that have never been produced before, even in the lab. For example, in this preliminary work on tungsten alloys they considered combinations of 12 different elements, including titanium, chromium, copper, silver and eight others. “Conventional approaches to designing alloys do not generally take grain boundaries into account but instead focus on how compatible the different metals are,” explains Schuh. “However, grain boundaries are crucial for creating stable nanocrystals, so we decided to include these in our calculations.”

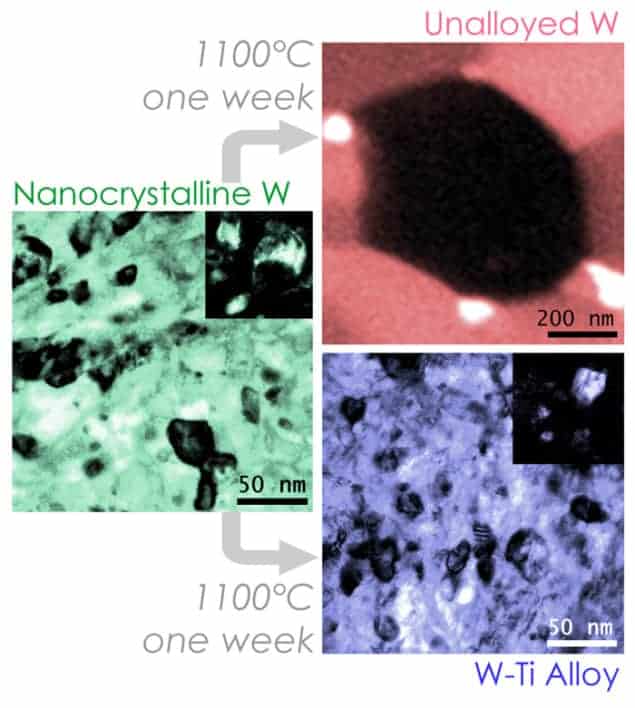

One particular alloy based on tungsten and titanium that the team created has titanium grains that are just 20 nm in size. It was found to remain stable for one week at annealing temperatures of 1100 °C and retained its exceptional strength during this time. It could thus find use in applications where high-impact resistance is needed, such as in industrial machinery or in armour, say the researchers.

“The methodology we developed in our work could easily be exploited to make other new nanostructured materials with equally good or even better strength and stability, and additional desirable properties such as corrosion resistance,” says Schuh. “Finding such alloys would be almost impossible by conventional trial-and-error methods but we are able to calculate which metal combinations work and which do not,” add team members Heather Murdoch and Tongjai Chookajorn.

The team is now busy detailing how its theoretical approach can be extended to many other alloys and structures – work that will be detailed in a future publication.

The work is reported in Science.