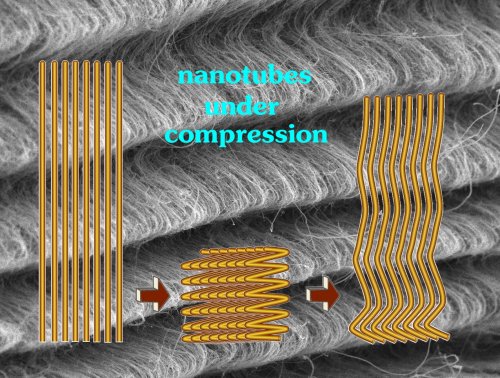

Scientists in the US have made foams from arrays of multiwalled carbon nanotubes. The nanotubes in the foam buckle to less than 15% of their original length when a load is applied. The foams could find use in a variety of applications, including cushioning pads and energy absorbing coatings (Science 310 1307).

Pulickel Ajayan of Rensselaer Polytechnic Institute and colleagues at the University of Hawaii at Manoa and the University of Florida created arrays of vertically aligned nanotubes by chemical vapour deposition. The nanotubes formed an open-cell foam system, with a porosity of around 87%.

In general, the more flexible the foam, the less strong it is. For example, increasing the voids in a typical foam increases its compressibility but rapidly lowers its strength. However, nanotube foams are unusual in that they are both extremely strong – with a compressive strength of 12 to 15 megapascals – and very flexible. In contrast, typical low-density flexible foams, such as latex rubber and polyurethane, have a compressive strength of about 20 to 30 kilopascals.

The team looked at the foams with a scanning electron microscope and found that the nanotubes formed regular buckles along their axis. “The most fascinating thing is that all the nanotubes unanimously buckle at the same wavelength towards the same direction – they do not buckle randomly,” says team member Anyuan Cao of the University of Hawaii. Moreover, the foams recover rapidly when the load is removed and have good fatigue resistance, suffering less than 15% deformation after thousands of cycles.

According to Cao, the nanotube foams could have applications as cushioning pads, energy absorbing coatings, and damping layers, while nanotubes with buckles could be used to make electromechanical devices such as actuators.

The scientists now plan to explore the electrical properties of compressed nanotubes by, for example, monitoring the change in electrical conductivity that takes place when the nanotubes buckle. They also aim to tailor the mechanical properties of the nanotubes for different applications by controlling the buckling wavelength, which determines the strength of buckled tubes, or by using aligned single-walled nanotubes.