The UK’s neutron and muon source, ISIS, has emerged from a major vacuum upgrade that will give researchers better tools for studying the structure of matter, reports Sunil Patel

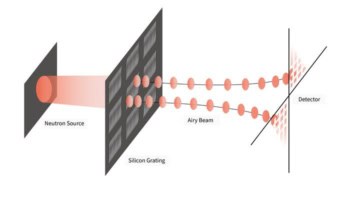

Discovered in 1932, neutrons have become a powerful tool to probe the structure of materials. Being electrically neutral, these unassuming subatomic particles are non-destructive and can penetrate much deeper into matter than charged particles such as electrons or electromagnetic waves such as X-rays. As such, neutrons provide complementary information to other analytical probes, and are particularly useful for detecting light atoms and for distinguishing neighbouring elements in the periodic table.

ISIS is located at the Rutherford Appleton Laboratory in the UK and is a world-leading neutron source for research in the physical and life sciences. The facility also produces muons, which provide a complementary probe to neutrons for studies of magnetism, superconductivity and charge transport. Using a suite of dedicated instruments, ISIS produces precisely tailored beams of neutrons and muons that tell researchers where atoms in a sample are and what they are doing, allowing new materials and even integrated devices to be designed. In terms of scientific output, ISIS underpins more than 400 publications in peer-reviewed journals every year, spanning topics from alternative fuels for transportation to new pharmaceutical compounds.

Growing demands

Since ISIS produced its first neutrons 30 years ago, the facility has grown and evolved. In 2008 a second target station (TS2) was added to meet the growing demands of the bioscience and advanced-materials communities, for example. Recently, ISIS has emerged from a six-month shutdown, during which key parts of the vacuum system were refurbished in order to meet the growing demands of users.

Unlike reactor-based neutron sources, such as the Institut Laue-Langevin in France, ISIS is an accelerator-based source – one of the first of its type. Neutron production begins with an ion source that sends negatively charged hydrogen ions to a radio-frequency (RF) quadrupole accelerator, where they are focused, grouped into bunches and accelerated. The ions are then passed through a 50 m-long linear accelerator (linac), which boosts their energy to 70 MeV. After passing through alumina foil, the negative hydrogen ions are stripped of their electrons to leave protons, which are then accelerated in bunches to 800 MeV in a 163 m-circumference synchrotron. Finally, neutrons are created via spallation by firing the high-energy protons into a tungsten target to produce a wide angular spread of neutrons. These are then channelled to various instruments surrounding the target, where different experiments are carried out by more than 1000 individual users each year. Muons are produced by passing the protons through an intermediate graphite target before they reach the tungsten target.

Vacuum technology is critical for ISIS, both for minimizing beam-scattering effects in the linac and synchrotron, and for ensuring that neutrons and muons that have bombarded a sample do not undergo any further scattering effects before they reach the detectors. There are 25 turbo pumps in the linac, with pumping speeds ranging from 300–2000 l/s. The synchrotron is pumped by 54 ion pumps, which are 400 l/s triodes. Special RF-screened and all-metal gate valves are used to minimize beam disturbance and to isolate the different parts of the vacuum system. Residual gas analysers monitor vacuum systems in the linac and also keep the gas composition in each of the two target stations in check. All this equipment is operated and monitored using control systems designed and maintained by in-house support staff. While vacuum pumps and gauges with on-board electronics are becoming increasing popular, such equipment cannot be used on parts of ISIS because of the effects of radiation.

Both the linac and synchrotron operate in the high-vacuum region, typically 5 × 10–6–10–7 mbar. In addition to minimizing beam-scattering effects, this level of vacuum allows high voltages to be applied without the danger of electrical breakdown. Indeed, were the vacuum to fail to reach the required operational levels, then ISIS would not be capable of producing any neutrons or muons at all. Stainless-steel and ceramic vacuum vessels are used in the linac and synchrotron, with aluminium or indium seals used to join the vessels together. Quick-release clamps are used to minimize radiation exposure to personnel during maintenance.

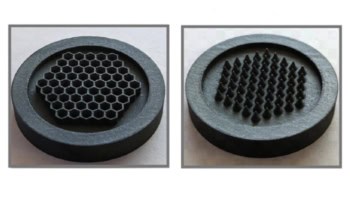

A dedicated staff of just five is needed for the running and maintenance of all ISIS vacuum equipment used in the linac, synchrotron and target stations, as well as on more than 25 instruments that are operational on the two target stations. The same team is also responsible for the manufacture of extremely delicate stripping foils used in the synchrotron and for carrying out rigorous tests of materials and equipment for vacuum compatibility prior to installation.

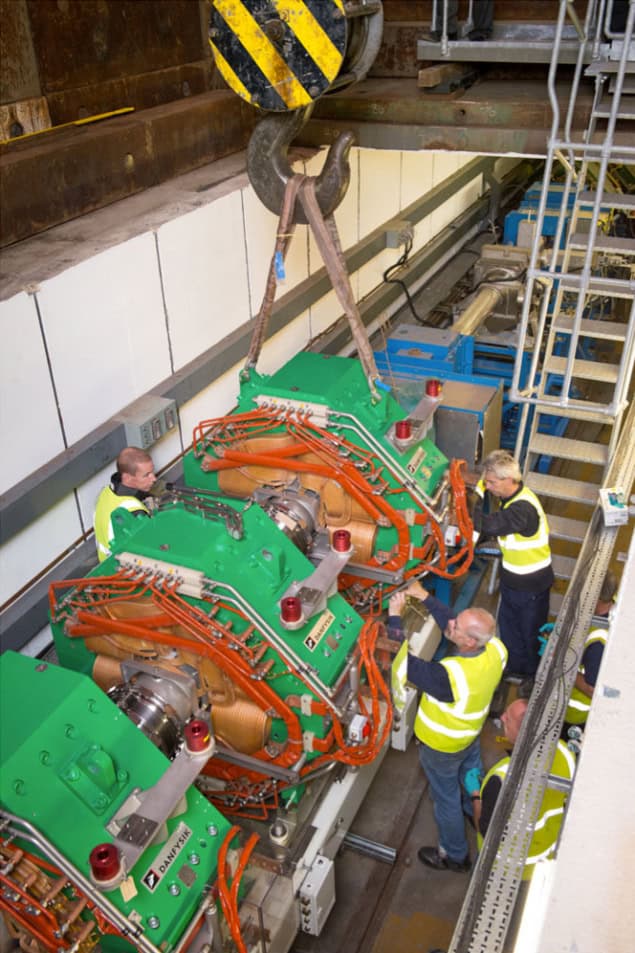

The ISIS vacuum system runs 24 hours a day, seven days a week and therefore regular maintenance is essential for ensuring the long-term reliability of the system. To achieve this high standard, the entire facility undergoes a scheduled six-month maintenance shutdown approximately every four years. Shorter 10–15 day shutdowns also occur every six to eight weeks of operation. The long shutdowns are not just an opportunity to carry out general maintenance on vacuum equipment such as pumps and gauges, they are also a chance for the major upgrades necessary to keep ISIS at the forefront of neutron science. Detailed planning and consultation takes place in the months prior to a long shutdown, and a full-size mock-up of part of the working area is constructed to help staff get to grips with the space constraints that they may find themselves working under.

ISIS emerged from its latest long shutdown in February, during which major changes were made to the systems that deliver the proton beam into Target Station 1 (TS1) and also to the “EC” muon instruments. Eight new quadrupole magnets, along with the vacuum beam pipe that fits in the centre of each magnet, were successfully installed. Four of these magnets lie on each side of the 7 mm-thick graphite intermediate target where muons are created. New and more reliable beam-positioning monitors were also installed to minimize beam losses that may occur during beam set-up.

Efficiency improvements

Following a detailed in-house review, the thin aluminium window that had previously separated the muon instruments from the intermediate target was also removed. This window had survived for more than 20 years on ISIS and was probably installed to protect the muon instruments from sudden pressure rises arising from either the intermediate or main targets. Its removal, in addition to further upgrades to the remaining magnets and vacuum pipework planned over the next 24 months, should result in at least a twofold increase in the overall muon flux. This will significantly reduce the time taken to acquire data from samples, allowing more experiments to be carried out in the time allocated to each user.

During the long shutdown, work also continued on the installation of two new instruments on TS2. IMAT and ZOOM were part of a suite of four new instruments funded from a £21m award from the UK government in 2011, following an initial TS2 investment of £130m. The ZOOM vacuum tank, containing a moveable detector, has a volume of almost 50 m3 and will be used for small-angle neutron-scattering experiments. IMAT, which will be used for imaging and diffraction experiments, has the longest vacuum guide section (approximately 46 m) of all instruments on ISIS. This length is needed to optimize the energy resolution of the instrument. Both instruments will undergo detailed commissioning in preparation for user experiments later in the year.

One of the biggest challenges of working on ISIS is pumping down vacuum vessels to operational levels quickly. Long pump-down times mean less beam time for users and, in the worst case, can prevent ISIS operations altogether if a problem were to occur with the vacuum systems in the linac, synchrotron or target stations. These systems were not designed to be “baked out”, which involves heating surfaces to above 100 °C to drive out water. As a result, out-gassing from water vapour can sometimes be a problem thanks to water’s tendency to stick to exposed surfaces. At the top of the ISIS vacuum group’s wish list is therefore a compact, dry, air-cooled vacuum pump that can pump at speeds of at least 100 m3/h at atmospheric pressure and can also deal effectively with large quantities of water vapour.

With more instruments to be installed on TS2 and further vacuum upgrades planned throughout the facility, planning has already started for the next major shutdown. This will ensure that ISIS continues to meet the growing demands of both academic and industrial users, and remain at the forefront of neutron and muon science for many years to come. These developments, along with expertise gained during 30 years of ISIS operation, are also proving vital for the development of new accelerator-based neutron sources, in particular the European Spallation Source under construction in Sweden, in which the UK is a key partner.