Optical fibres form the backbone of the Internet, carrying light signals across the globe. But some light is always lost as it travels, becoming attenuated by about 0.14 decibels per kilometre even in the best fibres. That means signals must be amplified every few dozen kilometres – a performance that hasn’t improved in nearly four decades.

Physicists at the University of Southampton, UK have now developed an alternative that could call time on that decades-long lull. Writing in Nature Photonics, they report hollow-core fibres that exhibit 35% less attenuation while transmitting signals 45% faster than standard glass fibres.

“A bit like a soap bubble”

The core of conventional fibres is made of pure glass and is surrounded by a cladding of slightly different glass. Because the core has a higher refractive index than the cladding, light entering the fibre reflects internally, bouncing back and forth in a process known as total internal reflection. This effect traps the light and guides it along the fibre’s length.

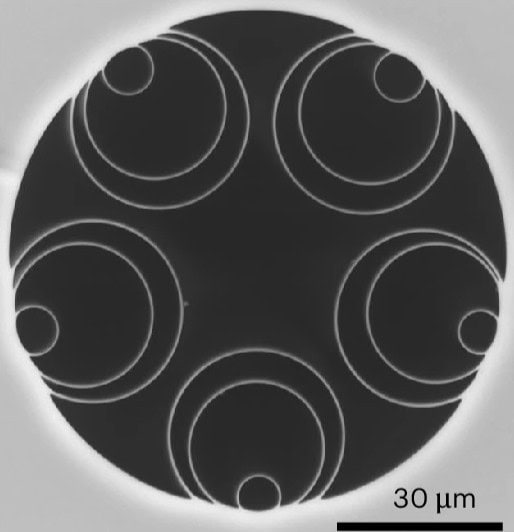

The Southampton team led by Francesco Poletti swapped the standard glass core for air. Because air is more transparent than glass, channelling light through it cuts down on scattering and speeds up signals. The problem is that air’s refractive index is lower, so the new fibre can’t use total internal reflection. Instead, Poletti and colleagues guided the light using a mechanism called anti-resonance, which requires the walls of the hollow core to be made from ultra-thin glass membranes.

“It’s a bit like a soap bubble,” Poletti says, explaining that such bubbles appear iridescent because their thin films reflect some wavelengths and lets others through. “We designed our fibre the same way, with glass membranes that reflect light at certain frequencies back into the core.” That anti-resonant reflection, he adds, keeps the light trapped and moving through the fibre’s hollow centre.

Greener telecommunications

To make the new air-core fibre, the researchers stacked thin glass capillaries in a precise pattern, forming a hollow channel in the middle. Heating and drawing the stack into a hair-thin filament preserved this pattern on a microscopic scale. The finished fibre has a nested design: an air core surrounded by ultra-thin layers that provide anti-resonant guidance and cut down on leakage.

To test their design, the team measured transmission through a full spool of fibre, then cut the fibre shorter and compared the results. They also fired in light pulses and tracked the echoes. Their results show that the hollow fibres reduce attenuation to just 0.091 decibels per kilometre. This lower loss implies that fewer amplifiers would be needed in long cables, lowering costs and energy use. “There’s big potential for greener telecommunications when using our fibres,” says Poletti.

Poletti adds that reduced attenuation (and thus lower energy use) is only one of the new fibre’s advantages. At the 0.14 dB/km attenuation benchmark, the new hollow fibre supports a bandwidth of 54 THz compared to 10 THz for a normal fibre. At the reduced 0.1 dB/km attenuation, the bandwidth is still 18 THz, which is close to twice that of a normal cable. This means that a single strand can carry far more channels at once.

Perhaps the most impressive advantage is that because the speed of light is faster in air than in glass, data could travel the same distance up to 45% faster. “It’s almost the same speed light takes when we look at a distant star,” Poletti says. The resulting drop in latency, he adds, could be crucial for real-time services like online gaming or remote surgery, and could also speed up computing tasks such as training large language models.

Field testing

As well as the team’s laboratory tests, Microsoft has begun testing the fibres in real systems, installing segments in its network and sending live traffic through them. These trials prove the hollow-core design works with existing telecom equipment, opening the door to gradual rollout. In the longer run, adapting amplifiers and other gear that are currently tuned for solid glass fibres could unlock even better performance.

Hollow-core fibre boosts optical gyroscope performance

Poletti believes the team’s new fibres could one day replace existing undersea cables. “I’ve been working on this technology for more than 20 years,” he says, adding that over that time, scepticism has given way to momentum, especially now with Microsoft as an industry partner. But scaling up remains a real hurdle. Making short, flawless samples is one thing; mass-producing thousands of kilometres at low cost is another. The Southampton team is now refining the design and pushing toward large-scale manufacturing. They’re hopeful that improvements could slash losses by another order of magnitude and that the anti-resonant design can be tuned to different frequency bands, including those suited to new, more efficient amplifiers.

Other experts agree the advance marks a turning point. “The work builds on decades of effort to understand and perfect hollow-core fibres,” says John Ballato, whose group at Clemson University in the US develops fibres with specialty cores for high-energy laser and biomedical applications. While Ballato notes that such fibres have been used commercially in shorter-distance communications “for some years now”, he believes this work will open them up to long-haul networks.