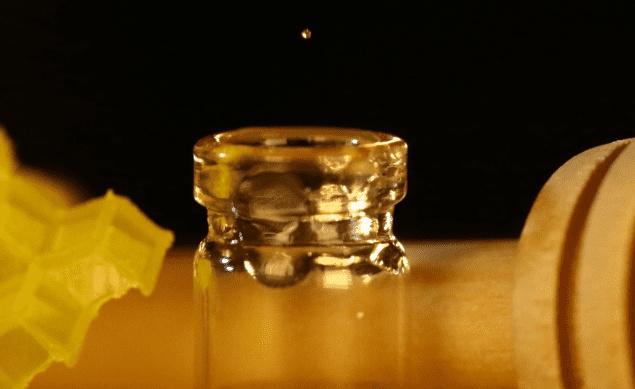

An acoustic printing method that uses highly viscous fluids such as honey has been developed by researchers in the US and Switzerland. The team claims that the technique overcomes viscosity-related limitations of other printing techniques and could open new avenues for the digital fabrication of materials with a wide range of physical properties.

Daniele Foresti, Jennifer Lewis and colleagues at Harvard University and ETH Zurich demonstrated the technique by printing patterns of food, optical resins, liquid metals, and a cell-laden collagen. The team claims the technology could be useful in the food, pharmaceutical and materials industries.

Inkjet printing is used for droplet-by-droplet patterning of liquids in many applications beyond the familiar computer printer. These include the creation of biological microarrays and additive manufacturing techniques. However, the inkjet is only really suitable for low viscosity fluids.

Cell-laden solutions

“Inkjet printing is the most common technique used to pattern liquid droplets, but it’s only suitable for liquids that are roughly ten times more viscous than water,” Foresti explained to Physics World. “Yet many fluids of interest to researchers are far more viscous. For example, biopolymer and cell-laden solutions, which are vital for biopharmaceuticals and bioprinting, are at least 100 times more viscous than water. Some sugar-based biopolymers could be as viscous as honey, which is 25,000 times more viscous than water.”

There are other techniques for printing highly-viscous fluids, such as laser-induced forward transfer. This uses lasers to induce a phase change in a film that then ejects droplets of the material for use in printing. But according to Foresti and colleagues, these techniques require various printing parameters to be adjusted when the ink composition changes. This makes the techniques challenging to use with materials whose physical properties change over time.

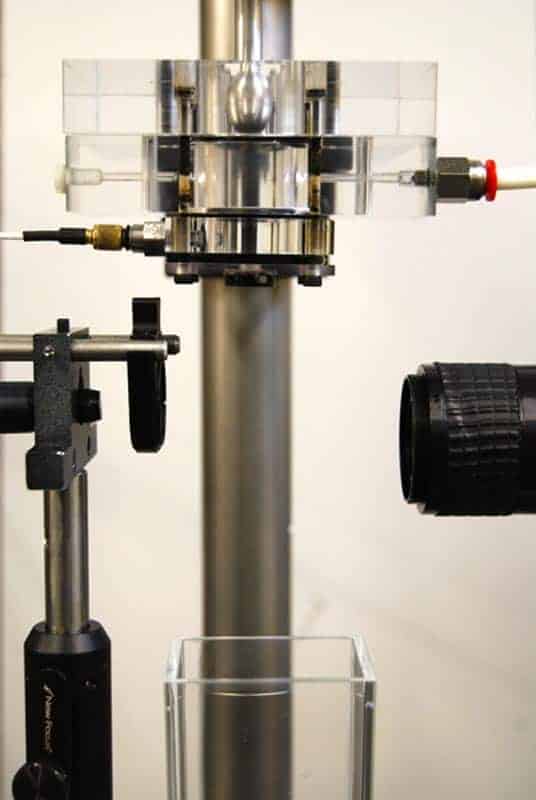

The more viscous a fluid is, the more resistant it is to flow. This means high-viscosity fluids exit print nozzles very slowly and in large droplets, which makes it difficult to produce sufficiently small droplets for printing. To solve this problem, the researchers turned to acoustics. They placed their printer nozzle inside a custom-made subwavelength acoustic chamber. This allowed them to use a single transducer to produce a highly-confined sound field around the tip of the nozzle. By generating forces up to 100 times greater than normal gravitational forces, the acoustic field pulled droplets of fluid off the nozzle.

Decoupled detachment

The team controlled the size of droplets falling from the nozzle by adjusting the amplitude of the sound waves. As the amplitude increases, the droplet size decreases. Foresti says, “This characteristic allows us to decouple the droplet detachment process from the fluid flow.”

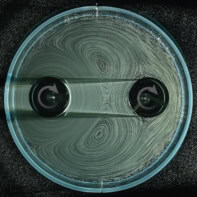

The researchers tested the process on food, and optical, electrically conductive and biological materials. For example, they printed honey droplets on white chocolate, a microlens array using transparent optical adhesive, and liquid metal.

“By harnessing acoustic forces, we have created a new technology that enables myriad materials to be printed in a drop-on-demand manner,” says Jennifer Lewis.

“This technique enables the manufacturing biopharmaceuticals, cosmetics, and food, and expands the possibilities of optical and conductive materials,” Foresti says.

Further improvements

Foresti and his colleagues were able to create and release droplet sizes ranging from 100-1000 μm in diameter. However, he believes that further improvements will increase the print resolution by decreasing the droplets size below 50 μm. “We are also working on multi-nozzle print heads to increase the throughput,” he adds.

Lab study could aid inkjet printing

Brian Derby, a material scientist at the University of Manchester, told Physics World that while this is an interesting technique, there are already other printing methods that do exactly the same thing, such as laser-induced forward transfer. “People are interested in printing viscous liquids, but this is just another way of doing it,” he says. It probably has advantages over other techniques, he adds, “but it probably has some disadvantages too”.

However, laser expert Robert Eason at the University of Southampton points out that laser-induced forward transfer is not a routine technique and currently has set-up costs of around £50,000. What would be great, Eason says, is a “technique that could print liquids of arbitrary viscosity on any surface”. But he says that while the acoustic method looks interesting it is too early to say whether it is a good, precise and repeatable option.

The new technique is described in Science Advances.