A compact, integrated titanium:sapphire laser that needs only a simple green LED as a pump source has been created by researchers at Stanford University in the US. Their design reduces the cost and footprint of a titanium:sapphire laser by three orders of magnitude and the power consumption by two. The team believes its device represents a key step towards the democratization of a laser type that plays important roles in scientific research and industry.

Since its invention by Peter Moulton at the Massachusetts Institute of Technology in 1982, the titanium:sapphire laser has become an important research and engineering tool. This is thanks to its ability to handle high powers and emit either spectrally pure continuous wave signals or broadband, short pulses. Indeed, the laser was used to produce the first frequency combs, which play important roles in optical metrology.

Unlike numerous other types of lasers such as semiconductor lasers, titanium:sapphire lasers have proved extremely difficult to miniaturize because traditional designs require very high input power to achieve lasing. “Titanium:sapphire has the ability to output very high powers, but because of the way the laser level structure works – specifically the fluorescence has a very short lifetime – you have to pump very hard in order to see appreciable amounts of gain,” says Stanford’s Joshua Yang. Traditional titanium:sapphire lasers have to be pumped with high-powered lasers – and therefore cost in excess of $100,000.

Logic, sensing, and quantum computing

If titanium:sapphire lasers could be miniaturized and integrated into chips, potential applications would include optical logic, sensing and quantum computing. Last year, Yubo Wang and colleagues at Yale University unveiled a chip-integrated titanium:sapphire laser that utilized an indium gallium nitride pump diode coupled to a titanium:sapphire gain medium through its evanescent field. The evanescent component of the electromagnetic field does not propagate but decays exponentially with distance from the source. By reducing loss, this integrated setup reduced the lasing threshold by more than an order of magnitude. However, Jelena Vučković – the leader of the Stanford group – says that “the threshold was still relatively high because the overlap with the gain medium was not maximized”.

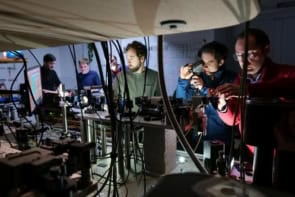

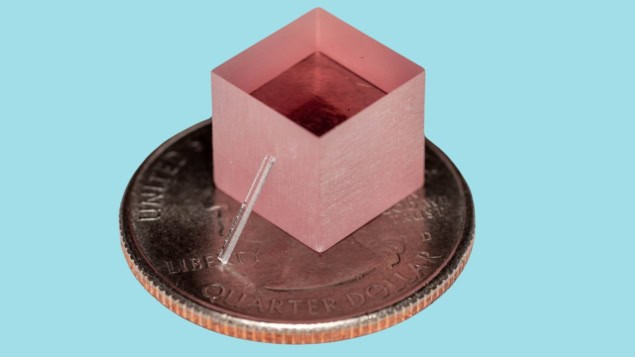

In the new research, Vučković’s group fabricated their laser devices by creating monocrystalline titanium:sapphire optical resonators about 40 micron across and less than 1 micron thick on a layer of sapphire using a silicon dioxide interface. The titanium:sapphire was then polished to within 0.1 micron smoothness using reactive ion etching. The resonators achieved almost perfect overlap of the pump and lasing modes, which led to much less loss and a lasing threshold 22 times lower than in any titanium:sapphire laser used previously. “All the fabrication processes are things that can be done in most traditional clean rooms and are adaptable to foundries,” says Yang – who is first author of a paper in Nature that describes the new laser.

The researchers achieved lasing with a $37 green laser diode as the pump. However, subsequent experiments described in the paper used a tabletop green laser because the team is still working to couple the cheaper laser into the system into the system effectively.

Optimization challenge

“Being able to complete the whole picture of diode to on-chip laser to systems applications is really just an optimization challenge, and of course one we’re really excited to work on,” says Yang. “But even with the low optimization we start with, it’s still able to achieve lasing.”

The researchers went on to demonstrate two things that had never been achieved before. First, they incorporated the tunability so valued in titanium:sapphire lasers into their system by using an integrated heater to modify the refractive index of the resonator, allowing it to lase in different modes. They achieved single mode lasing in a range of over 50 nm, and believe that it should be possible, with optimization, to extend this to several hundred nanometres.

Soap bubbles transform into lasers

They also performed a cavity quantum electrodynamics experiment with colour centres in silicon carbide using their light source: “That’s why [titanium:sapphire] lasers are so popular in quantum optics labs like ours,” says Vučković; “If people want to work with different colour centres or quantum dots, they don’t have a specific wavelength at which they work.” The use of silicon carbide is especially significant, she says, because it is becoming popular in the high-power electronics used in systems like electric cars.

Finally, they produced a titanium:sapphire laser amplifier, something that the team says has not been reported before. They injected 120 pJ pulses from a commercial titanium:sapphire laser and amplified them to 2.3 nJ over a distance of 8 mm down the waveguide. The distortion introduced by the amplifier was the lowest allowed by the laws of wave motion – something that had not been possible for any integrated amplifier at any wavelength.

Yubo Wang is impressed: “[Vučković and colleagues have] achieved several important milestones, including very low-threshold lasing, very high-power amplification and also tuneable laser integration, which are all very nice results,” he says. “At the end of the paper, they have a compelling demonstration of cavity-integrated artificial atoms using their titanium:sapphire laser.” He says he would be interested to see if the team could produce multiple devices simultaneously at wafer scale. He also believes it would be interesting to look at integration of other visible-wavelength lasers: “I’m expecting to see more results in the next few years,” he says.