A research team headed up at Korea Polytechnic University has developed a 3D bioprinting technique that enables the biofabrication of complex, multi-material and multi-cellular tissues with a single extrusion print head. The technique uses a special cartridge with multiple compartments that keep the bioink – a 3D culture biomaterial mixed with cells – within a pre-defined formation that is maintained upon printing. The cartridge and bioprinting procedure also allows the extrusion of bioink to create a 3D tissue for use in medical research or regenerative medicine (Biofabrication 10 035008).

The ability to pre-load different materials and cells into the printing cartridge simplifies the bioprinting process from an engineering standpoint, with only one print head and cartridge being needed to form a complex 3D tissue. The alternative, which is used for most extrusion-based bioprinting techniques, is to have multiple print heads filled with different bioinks and cells that are used in conjunction to print the different components of an engineered tissue.

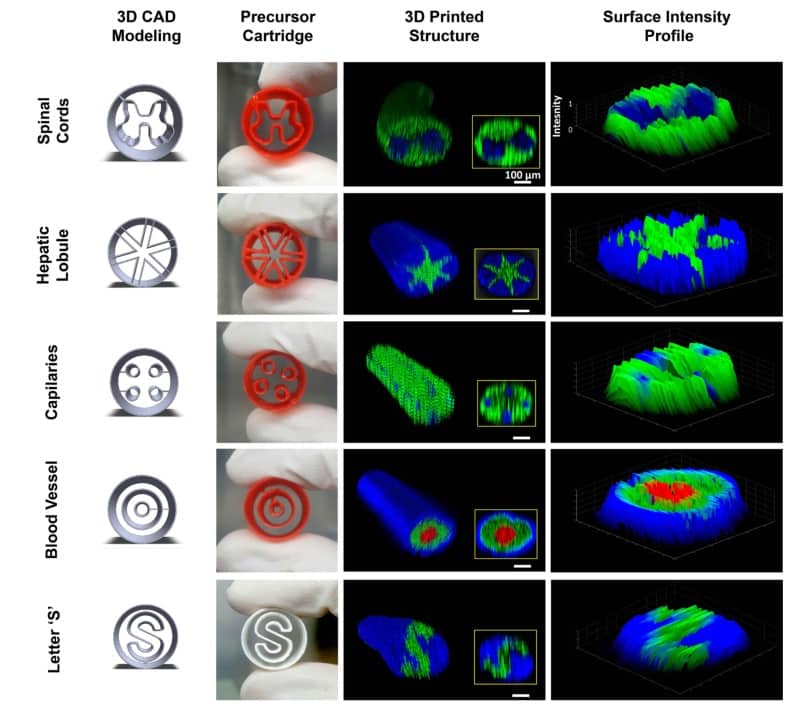

The researchers used a commercial 3D printer to manufacture the special cartridges, which enables the technique to be adapted in line with the user’s needs. The flexible design allows the technique to be applied within different bioprinter systems, as the cartridges can be 3D printed with precise dimensions to fit within a pre-existing a syringe head. This versatility also enables the printing cartridges to be designed for a specific tissue type, which the research group has exemplified by creating cartridges for biofabrication of spinal cords, hepatic lobules, capillaries, blood vessels, and even the letter “S”.

Whilst the cartridges are large (9.3 and 15 mm), the printing nozzles are much smaller (200, 250, 400, 610 and 840 μm), meaning that bioinks loaded into the syringe are miniaturized through the printing process. This miniaturization does not deform the final printed construct from its pre-defined structure, so is not an issue for biofabrication of tissues.

The pre-set technique enables the use of a larger printing nozzle – and subsequently increased post-print cell survival – as the engineered tissue is spatially orientated within the print cartridge; reducing the reliance upon small nozzles and low printing resolutions. The group exhibited this by printing the same construct with the pre-set bioprinting technique and a conventional extrusion bioprinting. They observed a lower rate of cell death from pre-set bioprinting.

The researchers used different bioinks of polymeric protein and polysaccharide origin to exhibit the capabilities of the technique, with differing concentrations of alginate and collagen being successfully printed. This means that different bioinks can be used to mimic the different physical environments of a complex tissue. The extracellular matrix (ECM) that surrounds cells is crucial to cell function and is composed of tissue specific proteins and polysaccharide concentrations, making the ability to bioprint cells in their bespoke bioink a useful feature.

Overall, this technique offers a versatile platform for the biofabrication of several tissues, with a reduced reliance upon microscale printing resolution. In future, it could be applied to print the tissue structures designed in this study, but could also be applied to many different tissue types. The advantage of a 3D bioprinting technique that is pre-defined by a 3D-printed cartridge is the vast scope for versatility that is only limited by the design stage. It will be interesting to see how this technique is used within the field of biofabrication moving forward.