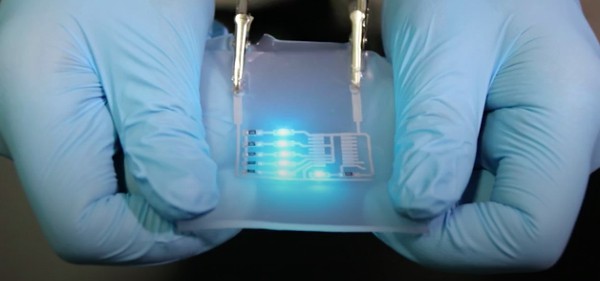

Stretchable biocompatible devices can be used in a host of medical applications, but most stretchable conductors made to date are toxic, expensive, difficult to make and break or degrade easily. A team of researchers at the National Center for Nanoscience and Technology in Beijing, China, has now printed the first flexible metal-polymer electronic circuits that are at once highly conductive and stretchable, biocompatible, non-toxic and easy and cheap to make. The circuits, which are made of eutectic gallium indium particles embedded in a polymer matrix, can take most 2D shapes and could find use in motion sensors, wearable glove keyboards, soft robotics and implantable devices to name but a few applications.

Eutectic gallium indium (EGaIn) is a liquid metal and can thus withstand large deformations. The material also boasts a high conductivity and is much less toxic than other metals that are also liquid at room temperature, such as mercury. Since it cannot be directly patterned using conventional techniques like stencil or ink-jet printing (its surface tension is too high), the researchers, led by Xingyu Jiang, embedded particles of the liquid metal onto the surface of a polymer (PMDS) instead. They did this by casting and peeling off steps rather than using a marker or nozzle.

The result is a printed conductive material with a good stretchability of 2.316 S/cm at a strain of 500% over more than 10 000 cycles of repeated stretching. Another advantage of the technique employed to make it is that the liquid metal particles remain on the surface of the substrate (rather than being buried deep inside), which means that functional electronic components can easily be mounted on top of them.

Many applications

The researchers used the printed metal-polymer conductors in a variety of applications, including in sensors for wearable keyboard gloves, motion sensors and in electrodes for electroporation (stimulating the passage of DNA through the membranes of live cells).

“The applications of the metal-polymer conductors depend on the polymer employed,” says study first author Lixue Tang. “We cast super-elastic polymers to make metal-polymer conductors for stretchable circuits or biocompatible and biodegradable polymers when we want to make implantable devices. In the future, we could even build soft robots by combining electroactive polymers.”

The technique can be used to make printed materials that can conform to any 2D shape, say the researchers. And they can be made in different thicknesses with varying electrical properties depending on the concentration of the liquid metal inks employed. This means that they could be used in a host of biomedical applications, including flexible patches that could even be wrapped around the heart to monitor and treat cardiac disease.

Indeed, the researchers say that they are now planning to fabricate a biodegradable cardiac patch patterned by their metal-polymer conductor electrodes to enhance the conductivity of myocardial cells and monitor electrophysiological signals. The applications are many: “Wearable electronics, implantable devices, soft robotics, future fabrics, virtual/augmented reality, flexible displays, artificial organs, brain-computer interfaces, and wherever biocompatible, soft electronics is necessary,” says Tang.

The research is detailed in iScience 10.1016/j.isci.2018.05.013.