Daniel Shaddock is co-founder of Liquid Instruments and professor of physics at the Australian National University in Canberra. He spoke with Hamish Johnston about innovation in the test and measurement industry

Much of your research career has focused on using optics to measure tiny variations in gravity, including gravitational waves. Can you describe your academic work?

My primary research interests are in optical metrology and I have worked on the LIGO and LISA gravitational-wave detectors. I’m a very goal-oriented person and I was very much attracted to the great measurement challenges of gravitational wave detection when I started working in the field as a postgraduate student in 1996. It seemed like an impossibly difficult problem: how do you make the world’s most sensitive measurement device? I was working with hundreds of other researchers, which I think made us all feel a little bit less crazy. It was very gratifying when gravitational waves were detected by LIGO in 2015.

During my early career, I became very interested in the problem-solving aspects of measurement. We had spent so much time and effort building LIGO technology, and I began to think about how we could share it with the rest of the world to solve other measurement challenges. That is what drove me to look deeper into understanding measurement technology at a very fundamental, scientific level.

You founded Liquid Instruments in 2014 because you were frustrated with the lack of innovation in the test and measurement industry. What were the problems with kit on offer at the time?

It is one of those industries that hasn’t changed in many, many decades. People who used an oscilloscope back in the 1970s or even the 1960s would find modern instruments familiar. Test equipment had not kept up with how we interact with technology – it was not fun to use. So many other industries had improved and adapted their products in light of modern digital technologies it made me realize that if we improved how people interact with their equipment it would improve their lives in the lab.

Around that time my gravitational-wave research was moving away from ground-based detectors like LIGO to space-based detectors like LISA Pathfinder. This meant that we had to change the way that we made measurements. LIGO has something like 100,000 measurement channels and requires an army of graduate students and postdocs to keep it humming. You can’t do that in space so the challenge was to create a new type of measurement system that you could launch on a rocket and operate remotely for a decade. We realized that we had to move from a physical, hard-wired approach to test and measurement towards a computer-based system that used intelligent software.

Is that when you started using field-programmable gate array (FPGA) computer chips?

Yes. The problem with trying to do test and measurement with a conventional computer is that it does not have the physical connections to the real world that are needed to make accurate measurements. But there was a new type of computer chip that I’d heard about while at Caltech back in the late 1990s – the FPGA. An FPGA is a computer that can be completely reconfigured and rewired in a fraction of a second. The FPGA seemed like a useful platform for merging the world of computers with the world of hardware and making something that is greater than the sum of its parts.

We realized that we could use the FPGA to replace a large swathe of conventional instrumentation including oscilloscopes, spectrum analysers, signal generators and lock-in amplifiers. There are tens, or maybe even more than 100 different types of devices that can be created using FPGAs.

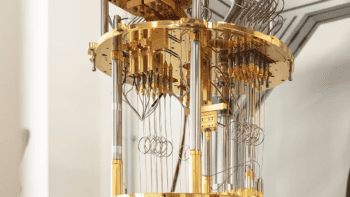

Moku-Pro can run many instruments at once, which are able to communicate with each other

What are the benefits of the FPGA approach?

We had started using FPGAs to create a phasemeter for the LISA gravitational-wave detector. We didn’t choose an FPGA-based architecture because of its flexibility. We chose it at the time because it was the only way we could get the performance that was required by LISA.

However, we quickly realized that we could reconfigure the FPGA to run as an oscilloscope, or perhaps as a spectrum analyser. Crucially, we noticed that this approach had a lot of advantages. It meant we didn’t have to go and fight for equipment with the other researchers in a lab where we only had one spectrum analyser. It also meant that we could run experiments remotely because we didn’t have to physically plug in or unplug cables to switch instruments.

Another important benefit of our FPGA approach is that we could use software to customize the instruments to do exactly what we wanted. If we wanted to change the filter on our lock-in amplifier, for example, we didn’t have to crack open the box and get out a soldering iron.

We could create an enormous variety of instruments with a single device. And because that device was incredibly useful, we made the effort to engineer it to a high standard. We started loaning our instruments out to our colleagues around the world, and we noticed that they would never give them back. They would refuse to return them. And we thought, “Oh, that’s interesting.”

Is that when you realized the commercial potential of the FPGA approach?

Yes, our software-defined approach gave us flexibility, scalability and upgradeability. The technology was improving rapidly, and it was clear to me that it would dominate the test and measurement industry in five or 10 years. At the same time, the computing industry was focused on improving user experience and this made us realize that we had a really compelling product.

So you launched your first product, Moku:Lab in 2016. What was it like?

We released Moku:Lab as our minimum viable product and had three instruments on it: an oscilloscope; a spectrum analyser; and a waveform generator. Today those first customers can now run 12 instruments by simply updating an app on an iPad. This approach is becoming common throughout the technology sector – products that get better over time. This is unlike conventional test equipment, which cannot be easily upgraded once you buy it.

How was Moku:Lab first received?

When we started the company my team and I had a pretty good reputation for developing instrumentation. So rather than being dismissed, people thought, “There are some pretty serious people behind Liquid Instruments, and if they think it’s a good idea, then it’s probably worth having a second look”. Our initial reputation was particularly strong in the university market because I was a professor of physics at the ANU, which is a top-ranked university.

We found that experimental physicists and engineers are a forward leaning bunch and are willing to try out new technologies. These tend to be the people who are the first to adopt new personal technologies amongst their friends – or as a kid they were probably in charge of programming the family’s VCR timer. We had a large number of supporters in the early days who immediately saw the potential benefits of our approach and realized that our first attempt was not going to be perfect.

As we pushed into new markets, we found that different sectors have different appetites for risk when adopting new technologies. Also, there is some very interesting psychology involved when people encounter new technologies. We discovered this when we released the first new instruments for Moku:Lab – which included a phasemeter and a lock-in amplifier. We were selling the device at the time for $5000 and we were hearing two very different things. The first was, “Well, I don’t use all these instruments, so I’d like a discount.” A second group of people said to us, “Oh my goodness, this is just amazing value. If you’re really providing all these instruments at that price, they can’t be very good. They must all be rubbish.”

So, we ended up making a cheaper version of Moku:Lab, which had fewer instruments, and we made a more expensive version, which now comes with 12 instruments. Commercially, this turned out to be one of the best decisions that we made.

One of those versions is designed for use in undergraduate labs. How did that market emerge?

We noticed that a lot of people were using the original Moku:Lab in undergraduate labs, but it was never really designed for that application – it was far too expensive and far too high performance. But universities found that students really enjoyed using it. They found it engaging, compelling and unintimidating to use because it spoke to the way they interacted with personal technology devices. Another plus was that Moku:Lab simplified measurement in the lab and therefore allowed students to focus on the concepts that they were meant to be learning.

However, the original version was too expensive so we came out with Moku:Go last year. It costs around $600 and it replaces an entire undergraduate bench top in a typical electrical engineering or physics lab. It’s been a real hit and we have already sold more Moku:Gos than we have sold Moku:Labs in the history of the company. We believe it has the potential to democratize scientific education around the world and improve the student experience. Indeed, students have written to us saying that they didn’t enjoy or understand their lab work until they started using Moku:Go – which is very gratifying.

You have also released a high-end version of Moku:Lab

Since 2016 we have gained a lot of experience, we’re a much larger company, and we have a lot more engineering prowess in the team. That has allowed us to launch our new flagship product, Moku:Pro. It’s the product that we wish we could have made at the beginning, but it just took us a little bit of time to get there. It can compete with high-end instruments including oscilloscopes and it has really shown people what the future holds for test and measurement.

We have taken advantage of the fact that FPGAs are getting bigger and bigger over time. Moku:Lab was designed to run as one instrument at a time – and at best it may be able to run a couple of instruments concurrently in the future. The FPGA in Moku:Pro is 10 times the size of the chip in Moku:Lab and this means that we can divide it up into several sections. Instead of having just one instrument running, it can run many instruments at once.

What’s more, these instruments can communicate with each other using high bandwidth, lossless and low-latency signals that never leave the chip. Moku:Pro is effectively an alternative to the large PXI and VXI systems that are currently ubiquitous in high-end labs and engineering and manufacturing facilities around the world.

Another first for us is that Moku:Pro users can program the FPGA with their own instruments using simple tools that we provide. All you need is a web browser – there’s no software to install – and you can build your own instrument from scratch, and then have it running in the lab in a matter of minutes. That has really opened up people’s eyes to possibility that they can use Moku:Pro to build exactly the measurement solution that they need.