Scientists from the University of Birmingham and the University of Warwick have unveiled a new class of polymeric four-dimensional (4D) printable resins for use in soft-tissue engineering.

Commercialized by 4D Biomaterials under the tradename 4Degra, the resins display the physical properties needed to promote tissue regeneration following injury or surgery. When printed into scaffolds, they exhibit high compressibility and strain recovery, meaning that they can be used to create self-fitting, void-filling support structures. Moreover, their interconnected pore network allows cells to infiltrate the scaffold, which promotes ingrowth of tissue and blood vessels.

“4Degra is the first biocompatible and fully biodegradable UV-cured resin for 3D printing,” says lead researcher Andrew Dove. “This means that complex shapes tailored to an application can be printed with high resolution using UV-based 3D printing methods.”

Filling the void

For patients with soft-tissue trauma, regions of tissue loss (“dead space”) severely limit the healing process. The cells responsible for tissue regeneration cannot proliferate inside the dead space, leading to deformities.

Because shape memory materials conform to the dimensions of their surroundings, they can fill these voids and subsequently provide a physical structure for cells to migrate into. This ensures consistent tissue support during the healing process.

The polycarbonate-based 4Degra resins are formulated with a photo-initiator and photo-inhibitor to ensure that they rapidly form gels when exposed to visible light, making them compatible with stereolithography-based 3D printing techniques.

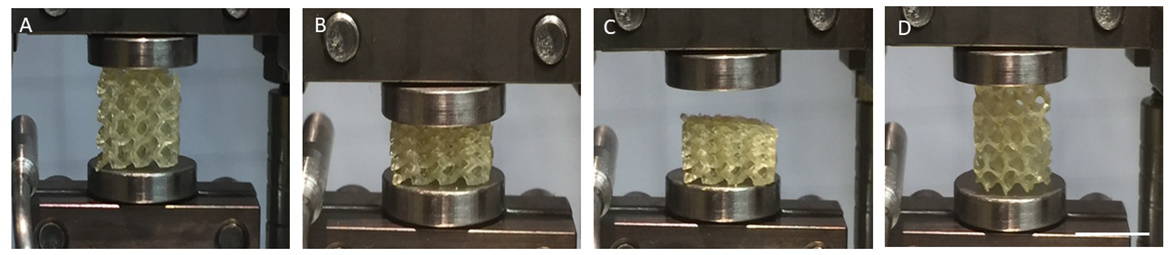

By modulating the resin composition, the researchers printed porous scaffolds with a wide range of thermomechanical properties. In addition, the scaffolds demonstrated excellent shape-recovery properties (up to 85% compressibility and less than 1 N expansion force) when inserted into alginate gel, a soft-tissue-mimicking material. These results suggest that the scaffolds can be implanted inside the body via minimally invasive surgery, without inflicting pressure (and therefore pain) on the surrounding tissues.

The researchers also tested the biocompatibility of their scaffolds in a mouse subcutaneous model. After two months, they observed that adipocyte (fat) cells had infiltrated the pores and formed lobules, indicating healthy tissue regeneration. Interestingly, less scar tissue formed on the porous scaffolds than on solid polycarbonates investigated for comparison. The researchers concluded that the increased surface area of the porous scaffolds further improved the biocompatibility of the resins.

Controlled degradation

Long-term studies confirmed that the scaffolds can support tissue ingrowth for more than a year. The resins slowly degrade into non-acidic products throughout the tissue healing process, but maintain enough mass to provide the much-needed mechanical support in the early stages of cell infiltration.

“Polycarbonates facilitate healing while reducing the risk of acidosis [increased acidity in the blood] over the material’s lifespan,” explains Andrew Weems, first author of the study.

Precision scaffolds tailor biomaterials to promote wound healing

“When degrading, polycarbonates surface erode, meaning that the degradation and reduction in mechanical properties is more controlled. This is in contrast to many other biomaterials that bulk erode,” adds Dove.

Now that the researchers have validated the printability and the performance of the 4Degra resins, they are collaborating with partners to test the material in a variety of medical devices.

The team describes the research in Nature Communications.