If an unfortunate insect finds itself trapped inside a Nepenthes pitcher plant its chances of survival are pretty slim – these tube-shaped plants are lined with a slippery surface that causes victims to slide into a chamber filled with digestive juices. A group of researchers in the US has taken inspiration from these carnivorous plants to design a surface that is both slippery and highly repellent of external fluids. The scientists say their material would be cheap to produce in bulk and has a range of possible applications, including slippery pipes for the efficient transport of oil.

Nepenthes acquire their slipperiness from a thin lubricating film that lines the inside surface of these plants. These films are created when water or nectar becomes locked into microscale textures in the surface of the plant creating a continuous layer of lubrication. When the films come into contact with the oils on the feet of insects the friction is very low, making it difficult for these creatures to maintain their grip when attempting to climb out.

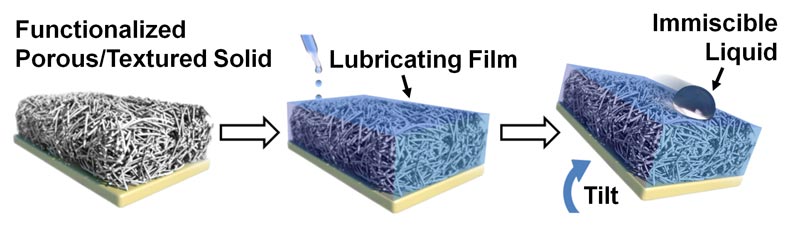

This technique for slipperiness used by Nepenthes has now been mimicked by Joanna Aizenberg and her colleagues at Harvard University who have created an “omniphobic” surface that repels oils as well as water. Described as a “slippery liquid-infused porous surface(s)”, or SLIPS, the surface is fabricated out of a sponge-like material composed of a random network of nanofibres. The material was then coated in a lubricating film that is immiscible to a broad range of liquids. When a drop of complex fluid, such as crude oil or blood, was placed on the surface, it quickly slid off even if the surface was tilted only slightly.

Robust slipperiness

The researchers say that one big advantage of the new material over alternative slippery surfaces in industry is its robustness. Materials based on the water-repelling properties of lotus leaves, for instance, rely on a layer of trapped air, which can become unstable at high pressures – leading to a poor performance or permanent damage. “[Our] lubricating film is intrinsically smooth, making it almost perfectly slippery toward substances of any surface tension,” Aizenberg told physicsworld.com. “Lotus-inspired surfaces have a much harder time repelling liquids with low-surface liquids, such as oils, since these tend to sink into the spaces between the textures.” She believes that the smooth nature of SLIPS means it could be used to create stain-resistant coatings on optical surfaces, such as solar cells and sensors.

The group is now working closely with other academic institutions to study various features of SLIPS, including its performance at extreme temperatures and high-shear conditions. They are also seeking industrial partners to commercialize different aspects of the SLIPS technology. “The temperature and pressure stabilities of SLIPS make it ideal for energy-efficient, high-temperature transport of economically important fluids such as crude oil and biofuels,” said Aizenberg. Aizenberg believes that SLIPS could also be used as ice-resistant coatings for instruments operating in refrigeration technologies, or even in polar environments.

Michael Nosonovsky, a biomimetics engineer at the University of Wisconsin-Milwaukee in the US, agrees that the technology shows a lot of promise. “One could use it for various purposes, such as household appliances, which will require much less cleaning or all applications where moving parts can stick together and prevent proper operation,” he said. Nosonovsky envisages that in the longer run SLIPS could be used in applications where biofouling is undesirable, such as underwater hulls of ships and submarines.

Chuan-Hua Chen, a hydrodynamics researcher at Duke University in the US, is also impressed by the new design. “This is a clever way to develop the slippery surface, which reminds me of the lubricants used in automobile engines and hydraulic machinery,” he said. Chen agrees that using a liquid lubricant eliminates a lot of problems associated with air-filled cavities, though he believes this feature could also be a weakness. “Lubricants would work well in enclosed machinery, but would have to be replenished if exposed,” he explained.

This research is published in Nature.