Surface slipperiness is a critical property within material development in the medical and technology fields. While materials with specific surface properties have been developed, few have demonstrated tunable slipperiness. Yuanjin Zhao and his group at Southeast University in Nanjing, China, hope to change this by developing a smart sponge with controllable wettability.

Wettability (the ability of a liquid to maintain contact with a surface) is a well-understood property that has been studied for more than 200 years. Stain-repelling clothing and anti-fogging windshield wiper fluids are both examples of materials with specifically designed non-wettable properties.

Zhao’s novel material goes beyond specific wettable-surface design by combining smart polymer trans-1,4-polyisoprene (TPI) with the well-known nanomaterial graphene. Smart polymers have mechanical properties that are sensitive to outside triggers. In this case, TPI changes shape when a voltage is applied. By covering a graphene sponge with TPI, Zhao and his group were able to control the shape of the graphene sponge using an outside voltage.

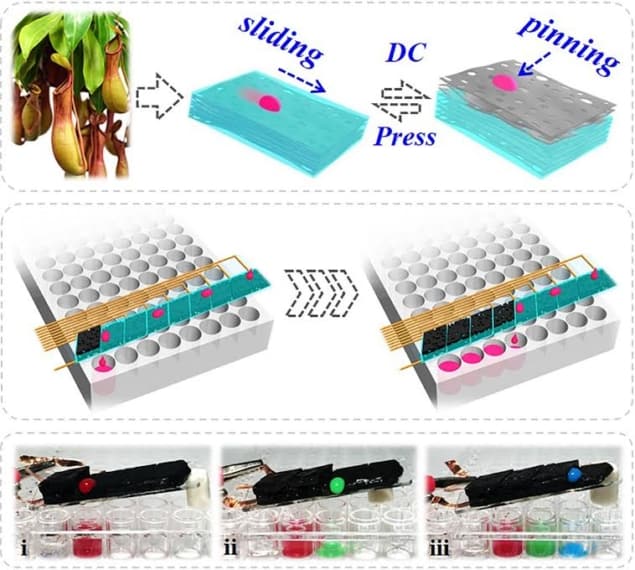

The sponge shape control was linked to wettability by covering the TPI–graphene sponge with a lubricant. Such a structure was partially inspired by the Nepenthes pitcher plant. When the sponge expands, the applied lubricant flows inside the sponge pores, causing the surface to become rough and irregular. But when the sponge contracts, the lubricant is forced out to create a slippery, sleek surface.

Zhao directly demonstrated the usefulness of the new material by using the sponge to pipette different solutions into a microplate. Microplates are frequently used in biological and medical labs but require a large number of pipetting steps. To make this process less labour intensive, one could load the different samples into specific wells located within the sponge. Samples could then be unloaded into the correct microplate well on demand.

Such a novel sponge can also be reused for different microplates and samples, as no liquid residues remain on the sponge well surface after the solutions are transferred. This is a huge advantage over traditional pipette tips, which must be disposed of to prevent sample contamination when working with different microplate wells. This property is directly related to the sponge’s change in surface wettability.

Zhao and his colleagues imagine such a unique sponge could also be used in microfluidics and biomedical instruments. Other applications include fuel storage and enclosure of micro-scale chemical reactions. Full details are reported in Science Advances.