A micron-scale “armour” that protects highly water-repellent nanostructures from damage has been developed by researchers in China and Finland. The new extra-durable coating could make it possible to employ these “superhydrophobic” surfaces on devices such as solar panels and vehicle windscreens that experience tough environmental conditions.

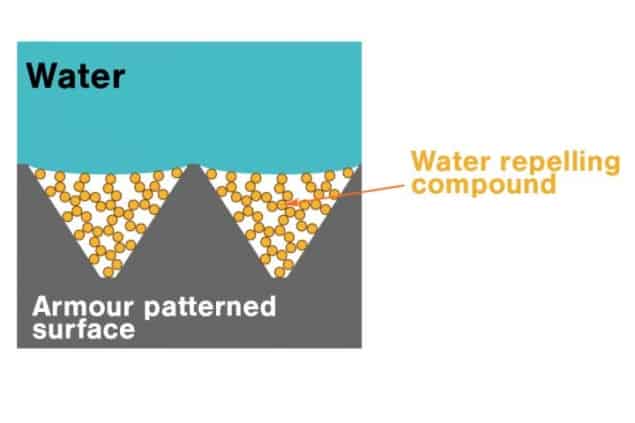

As their name suggests, superhydrophobic materials repel water extremely well. They owe this impressive ability to a thin layer of air that develops around nanometre-scale structures on their surface. By ensuring that droplets barely touch the solid part of the surface at all, the air layer effectively acts as a lubricant, allowing water droplets to roll off with near-zero friction.

These nanostructured surfaces are, however, mechanically fragile and can easily be wiped away. To address this drawback, a research team led by Xu Deng of the University of Electronic Science and Technology of China in Chengdu and Robin Ras of Finland’s Aalto University created a superhydrophobic surface containing structures at two different length scales: a nanoscale structure that is water repellent and a microscale one that provides durability.

The microstructure consists of an interconnected frame containing “pockets” of tiny inverted pyramids. Within these pyramids are the highly water-repellent and mechanically fragile nanostructures. The frame thus acts as a shield, preventing the nanostructure coating from being removed by abradants larger than the frame. “A finger, screwdriver or even sandpaper glides over these microstructures, leaving the nanostructures untouched, thereby preserving the surface’s attractive water-repellent feature,” Ras says.

A generic concept

Ras goes on to explain that the microscale armour could be made from almost any material. “It’s the interconnecting structure of the surface frame that makes it strong and rigid,” he says. “We made ours with pockets of different sizes, shapes and materials, including silicon, ceramics, metals and transparent glass. The beauty of this approach is that it is a generic concept that works for numerous materials, giving us the flexibility to design a wide range of durable waterproof surfaces.”

In one of their experiments, Ras, Deng and colleagues constructed a superhydrophobic surface from transparent glass and used it as a cover for solar cells. “One problem with solar cells is that when they are on rooftops or other difficult-to-reach places, they become gradually contaminated with sand and dust, which results in poorer efficiency over time,” Ras says. “For maintaining the high efficiency of current-generation solar panels, regular cleaning is needed, especially in places where there is a lot of dust in the air. Our durable water-repellent coating means that they get cleaned automatically by rain or dew.”

Withstanding difficult working environments

Other applications for the superhydrophobic surfaces include anti-icing and anti-fogging surfaces, he adds, or machines and vehicles that operate in harsh conditions. The surfaces may even have antimicrobial properties since bacteria, viruses and pathogens cannot cling to the nanostructures.

Insects inspire water-repellent material

To prove that their surfaces could withstand difficult working environments, the researchers put them through a battery of tests: baking them at 100°C for several weeks; immersing them in highly corrosive liquids for hours; blasting them with high-pressure water jets; and exposing them to extreme humidity while bending them. They even rubbed them with sandpaper and cut them with a sharp steel blade. None of these treatments appeared to affect the surfaces and they continued to repel liquids as effectively as before.

The team members, who report their work in Nature, say they now plan to commercialize their coatings. “The benefits for the user are that they can keep surfaces spotless and clean, function in otherwise challenging conditions and reduce downtime by doing away with the need for constant cleaning,” Ras tells Physics World.