The latest addition to Element Six’s DNV™ Series of synthetic diamond offers increased design flexibility to scientists and engineers working on next-generation quantum sensing systems

Design, development and at-scale fabrication of “perfectly imperfect diamonds”, uniquely tailored for quantum metrology applications such as compact magnetometers, RF sensors, solid-state gyroscopes and room-temperature masers. That’s the mission for the quantum team at Element Six, which is applying its patents and know-how in chemical vapour deposition (CVD) to mass-produce quantum grades of single-crystal diamond containing deliberate and controlled levels of so-called nitrogen-vacancy (NV) spin centres.

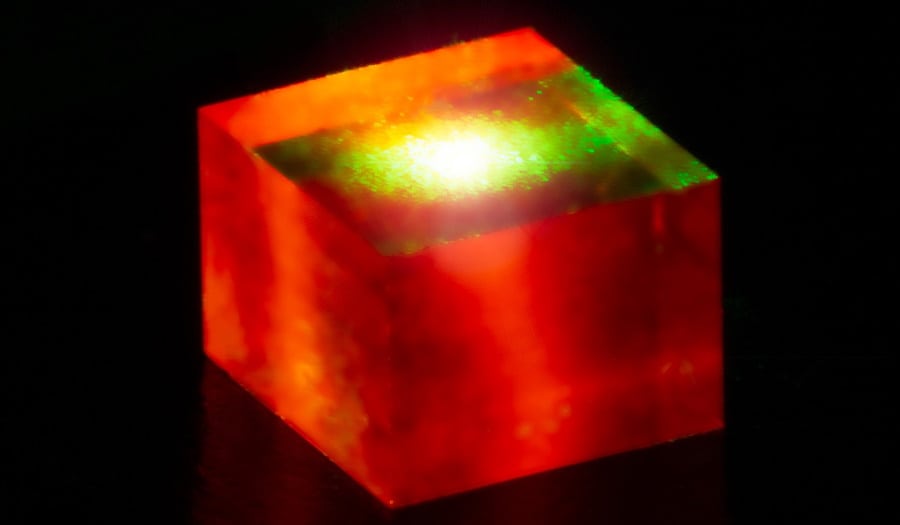

Among the hundreds of different types of defects that can be found within the carbon lattice, the NV centre is especially interesting to scientists and technologists because it can be manipulated to provide an optical output that is sensitive to magnetic and radiofrequency signals at room temperature. This process, known as optically detected magnetic resonance (ODMR), is observed when measuring a change in fluorescence after shining green laser light on a single NV defect, or on an ensemble of them, in the presence of an applied microwave field – an interaction that provides the basis for a versatile solid-state platform with spin qubits that can be initialized and read out with long qubit lifetimes (up to seconds in certain circumstances).

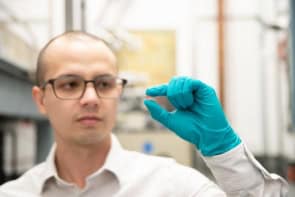

Andrew Edmonds, a principal research scientist at Element Six, tells Physics World how the company’s DNV Series of synthetic diamond is being deployed by research and industrial end-users for a raft of emerging applications in quantum science and technology.

How does Element Six support wider commercialization efforts in quantum R&D?

I’ve been with Element Six for eight years and, along with my colleagues in the R&D and product development teams, work closely with academic and industrial customers to support a broad spectrum of quantum applications where synthetic diamond offers a unique value proposition. Collectively, our task is to transform early-stage applications into mainstream commercial opportunities.

In a sense, what the Element Six quantum team is trying to do is make the “perfectly imperfect diamond”. Put another way: a synthetic diamond that contains a specific type of defect – the NV centre – without creating other defects that will have a detrimental effect on the material’s aggregate physical properties.

Advanced materials science and leading-edge fabrication: these are the key elements underpinning the innovation behind our DNV Series.

Element Six has just released DNV B14, the latest addition to its DNV Series of quantum-grade diamond. In what ways will this new product benefit your academic and industrial customers?

The DNV Series is designed to provide material with engineered NV centres that can be readily integrated into an industrial quantum device or a research experiment. Our new material, DNV B14, uses a uniform distribution of NV spin centres in a small diamond chip (3x3x0.5 mm) that can generate a much larger fluorescence signal compared with DNV B1, the first commercial product we launched as part of the DNV Series. The difference is evident in the physical appearance of the two materials: the DNV B1 crystal is pink under natural light while DNV B14 is a vivid purple (due to its 10x increase in NV defect concentration).

As such, the new material gives scientists and engineers greater flexibility when designing a quantum sensing device around the diamond, with some applications benefiting from a higher concentration of NV spin centres (typically 4.5 parts-per-million in DNV B14) and others better suited to the lower NV concentration offered by DNV B1 (around 300 parts-per-billion). It’s worth emphasizing, though, that while synthetic diamond forms an integral part of the quantum sensing device, the broader instrument package around the diamond is just as important.

So DNV B14 complements DNV B1 rather than supersedes it?

Correct. As a specialist materials supplier, we make a point of working closely with all our customers to understand their technical requirements at a granular level, ensuring they get the synthetic diamond best suited to their needs. That could mean detecting or tracking a magnetic field that is oscillating significantly in a known way – for which DNV B1 might be the optimum fit – or measuring small-scale perturbations in the Earth’s largely static magnetic field versus changing geography or location – for which DNV B14 might be a better option.

Are there more classes of synthetic diamond planned within the DNV Series?

The DNV Series is work-in-progress and our R&D roadmap includes plans to develop other classes of materials, characterized by NV centres in different concentrations and/or geometries, to address existing and nascent quantum sensing applications. Our priority right now is to lower diamond’s adoption barrier and seed early-stage quantum applications by giving researchers and industry the specialist materials they need to maximize scientific impact and commercial success.

Down the line, for example, it’s likely that users will require innovative variations on the DNV Series offering – perhaps thin layers of high-NV synthetic diamond on top of a really pure bulk diamond with minimal defects and impurities. Heterogeneous materials like this will open up new lines of scientific enquiry and enable users to build novel quantum devices – for example, imaging microscopes capable of mapping magnetic fields with unprecedented spatial resolution and nanoscale sensitivity.

Right now, what does the addressable market look like for the DNV Series?

We have a large number of university groups among our customer base – scientists doing the fundamental research on NV centres in quantum-grade diamond. At the same time, there’s growing engagement from industry, spanning across quantum technology start-ups – the likes of Qnami, SB Quantum and Quantum Diamond Technologies – as well as established, diversified instrumentation manufacturers like Bosch and Thales. The priority at Element Six is to get DNV Series diamond into the hands of the brightest researchers and engineers to deliver on the scientific and commercial promise of next-generation quantum sensing devices.

It seems there’s no shortage of applications for DNV Series diamond?

Our engineered diamond has already supported significant breakthroughs in quantum R&D. In 2018, for example, scientists at Imperial College London utilized our engineered single-crystal material in the world’s first continuous-wave, room-temperature solid-state maser (the microwave equivalent of a laser). Elsewhere, a team at the University of Warwick, UK, has demonstrated the world’s most sensitive fibre-coupled diamond magnetometer, an instrument that has the potential to be miniaturized for applications in healthcare diagnostics.

In the US, meanwhile, the aerospace and defence manufacturer Lockheed Martin has demonstrated a magnetometer built around quantum diamond to measure the direction and strength of nearly imperceptible anomalies in the Earth’s magnetic field. Ultimately, this sort of approach could yield an alternative to satellite-based GPS navigation systems – one that does not rely on external signals that can be jammed.

What are the main engineering and manufacturing challenges facing customers using DNV Series diamond for quantum sensing applications?

Quantum diamond underpins a whole new range of applications, many of which have no analogues in existing materials. Customers for this disruptive technology are academics and industrialists who are approaching the engineering and manufacturing challenges in different ways. The academic community, for its part, is focused on pushing the limits of what can be done, leading to paradigm shifts in technology performance.

Industry, on the other hand, is all about taking the current state-of-the-art and figuring out how best to package and integrate DNV Series diamond into quantum sensing platforms. Think reliability, robustness, manufacturability, scalability and cost/performance ratio. Given that context, one of the big advantages of DNV Series diamond is that it delivers a baseline of known and repeatable performance – though ultimately the final result also depends on the quality of the instrument users build around the diamond.

As a specialist materials company, how does Element Six secure its talent pipeline – in particular, the recruitment of PhD-level quantum physicists, materials scientists and device engineers?

Collaboration is embedded in Element Six’s DNA. It is the company’s long-term commitment to academia and industry that feeds our talent pipeline. This is perhaps even more true in the quantum space, where we can leverage our many long-standing collaborations with academic groups to recruit new talent, while also using that network to help our commercial customers speed up innovation and get devices to market faster.