Superconducting magnets inside a fusion reactor will experience conditions that aren’t seen anywhere on Earth. Materials scientists Susie Speller and Chris Grovenor are trying to predict how long these components can last in this extreme environment

Fusion – the process that powers the Sun – offers a tantalizing opportunity to generate almost unlimited amounts of clean energy. In the Sun’s core, matter is more than 10 times denser than lead and temperatures reach 15 million K. In these conditions, ionized isotopes of hydrogen (deuterium and tritium) can overcome their electrostatic repulsion, fusing into helium nuclei and ejecting high-energy neutrons. The products of this reaction are slightly lighter than the two reacting nuclei, and the excess mass is converted to lots of energy.

The engineering and materials challenges of creating what is essentially a ‘Sun in a freezer’ are formidable

The Sun’s core is kept hot and dense by the enormous gravitational force exerted by its huge mass. To achieve nuclear fusion on Earth, different tactics are needed. Instead of gravity, the most common approach uses strong superconducting magnets operating at ultracold temperatures to confine the intensely hot hydrogen plasma.

The engineering and materials challenges of creating what is essentially a “Sun in a freezer”, and harnessing its power to make electricity, are formidable. This is partly because, over time, high-energy neutrons from the fusion reaction will damage the surrounding materials. Superconductors are incredibly sensitive to this kind of damage, so substantial shielding is needed to maximize the lifetime of the reactor.

The traditional roadmap towards fusion power, led by large international projects, has set its sights on bigger and bigger reactors, at greater and greater expense. However these are moving at a snail’s pace, with the first power to the grid not anticipated until the 2060s, leading to the common perception that “fusion power is 30 years away, and always will be.”

There is therefore considerable interest in alternative concepts for smaller, simpler reactors to speed up the fusion timeline. Such novel reactors will need a different toolkit of superconductors. Promising materials exist, but because fusion can still only be sustained in brief bursts, we have no way to directly test how these compounds will degrade over decades of use.

Is smaller better?

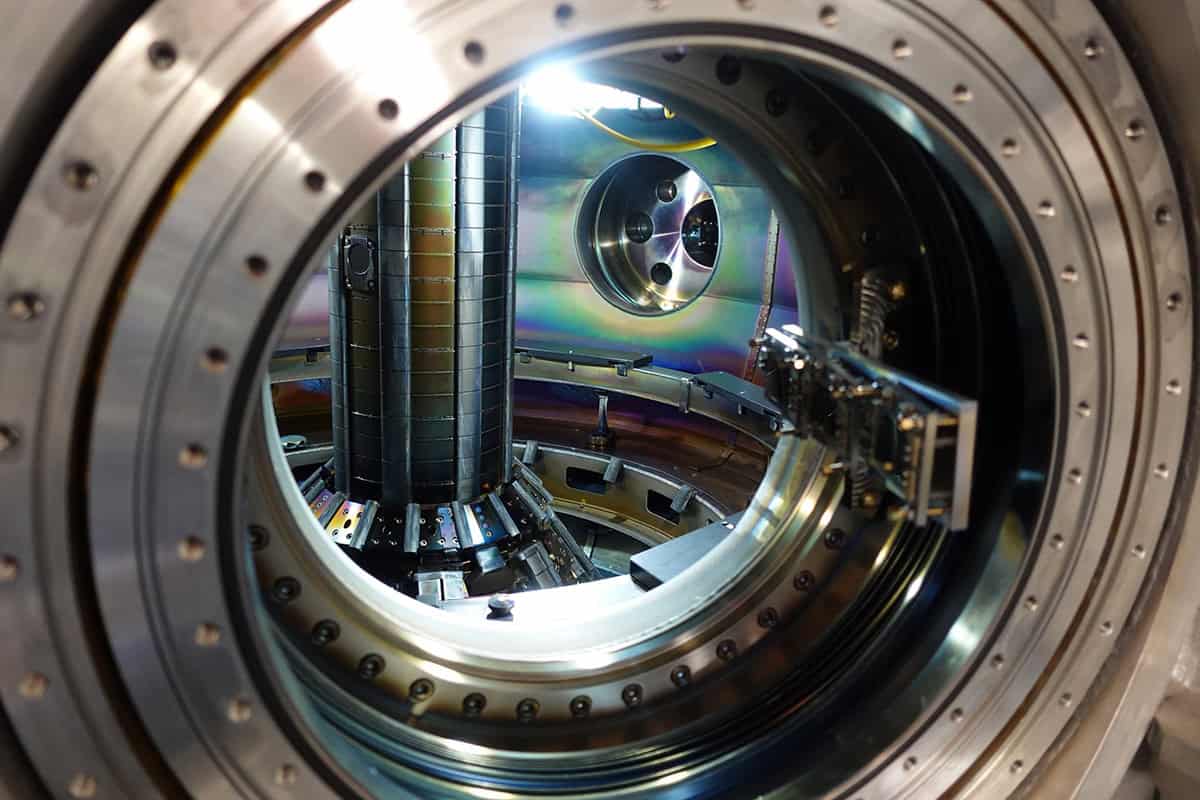

A leading concept for a nuclear fusion reactor is a machine called a tokamak, in which the plasma is confined to a doughnut-shaped region. In a tokamak, D-shaped electromagnets are arranged in a ring around a central column, producing a circulating (toroidal) magnetic field. This exerts a force (the Lorentz force) on the positively charged hydrogen nuclei, making them trace helical paths that follow the field lines and keep them away from the walls of the vessel.

In 2010, construction began in France on ITER, a tokamak that is designed to demonstrate the viability of nuclear fusion for energy generation. The aim is to produce burning plasma, where more than half of the energy heating the plasma comes from fusion in the plasma itself, and to generate, for short pulses, a tenfold return on the power input.

But despite being proposed 40 years ago, ITER’s projected first operation was recently pushed back by another 10 years to 2034. The project’s budget has also been revised multiple times and it is currently expected to cost tens of billions of euros. One reason ITER is such an ambitious and costly project is its sheer size. ITER’s plasma radius of 6.2 m is twice that of the JT-60SA in Japan, the world’s current largest tokamak. The power generated by a tokamak roughly scales with the radius of the doughnut cubed which means that doubling the radius should yield an eight-fold increase in power.

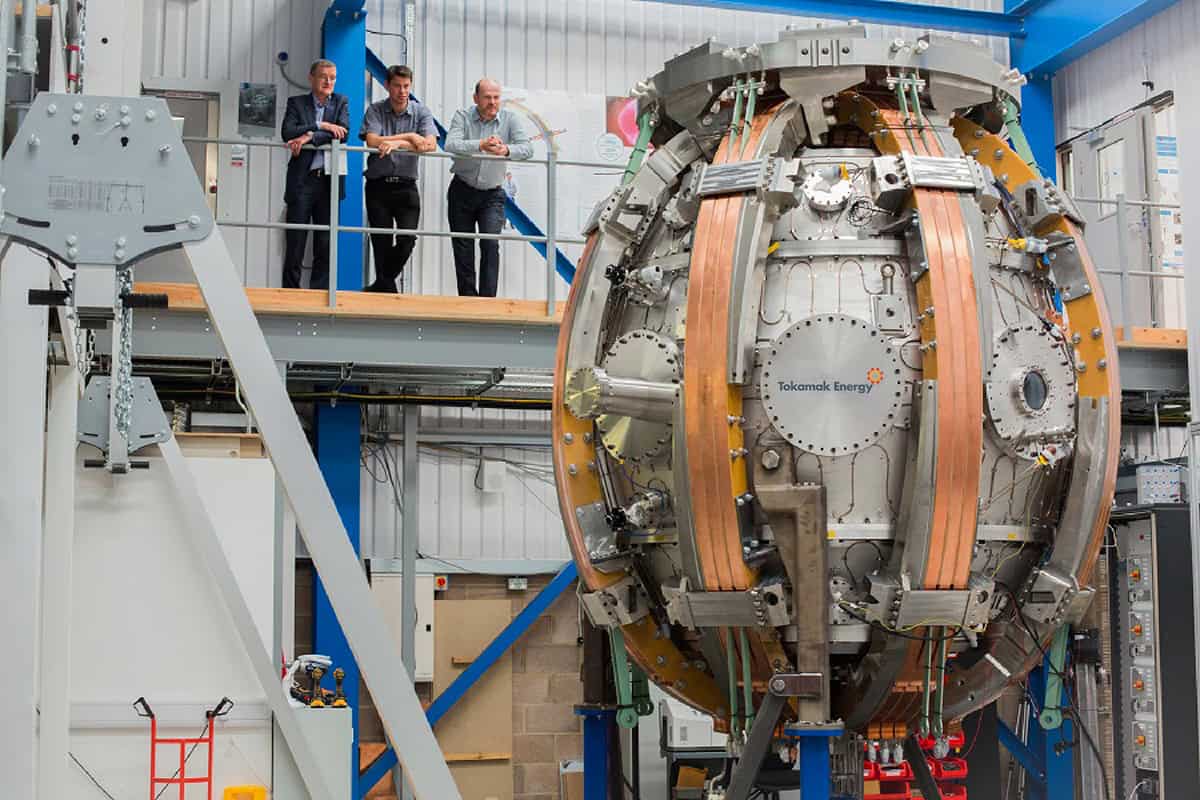

However, instead of chasing larger and larger tokamaks, some organizations are going in the opposite direction. Private companies like Tokamak Energy in the UK and Commonwealth Fusion Systems in the US are developing compact tokamaks that, they hope, could bring fusion power to the grid in the 2030s. Their approach is to ramp up the magnetic field rather than the size of the tokamak. The fusion power of a tokamak has a stronger dependence on the magnetic field than the radius, scaling with the fourth power.

The drawback of smaller tokamaks is that the materials will sustain more damage from neutrons during operation. Of all the materials in the tokamak, the superconducting magnets are most sensitive to this. If the reactor is made more compact, they are also closer to the plasma and there will be less space for shielding. So if compact tokamaks are to succeed commercially, we need to choose superconducting materials that will be functional even after many years of irradiation.

1 Superconductors

Superconductors are materials that have zero electrical resistance when they are cooled below a certain critical temperature (Tc). Superconducting wires can therefore carry electricity much more efficiently than conventional resistive metals like copper.

What’s more, a superconducting wire can carry a much higher current than a copper wire of the same diameter because it has zero resistance and so no heat is generated. In contrast, as you pass ever more current through a copper wire, it heats up and its resistance rises even further, until eventually it melts.

Without this resistive heating, a superconducting wire can carry a much higher current than a copper wire of the same diameter. This increased current density (current per unit cross-sectional area) enables high-field superconducting magnets to be more compact than resistive ones.

However, there is an upper limit to the strength of the magnetic field that a superconductor can usefully tolerate without losing the ability to carry lossless current. This is known as the “irreversibility field”, and for a given superconductor its value decreases as temperature is increased, as shown above.

High-performance fusion materials

Superconductors are a class of materials that, when cooled below a characteristic temperature, conduct with no resistance (see box 1, above). Magnets made from superconducting wires can carry high currents without overheating, making them ideal for generating the very high fields required for fusion. Superconductivity is highly sensitive to the arrangement of the atoms; whilst some amorphous superconductors exist, most superconducting compounds only conduct high currents in a specific crystalline state. A few defects will always arise, and can sometimes even improve the material’s performance. But introducing significant disorder to a crystalline superconductor will eventually destroy its ability to superconduct.

The most common material for superconducting magnets is a niobium-titanium (Nb-Ti) alloy, which is used in MRI machines in hospitals and CERN’s Large Hadron Collider. Nb-Ti superconducting magnets are relatively cheap and easy to manufacture, but – like all superconducting materials – it has an upper limit to the magnetic field in which it can superconduct, known as the irreversibility field. This value in Nb-Ti is too low for this material to be used for the high-field magnets in ITER. The ITER tokamak will instead use a niobium-tin (Nb3Sn) superconductor, which has a higher irreversibility field than Nb-Ti, even though it is much more expensive and challenging to work with.

2 REBCO unit cell

The unit cell of a REBCO high-temperature superconductor. Here the pink atoms are copper and the red atoms are oxygen, the barium atoms are in green and the rare-earth element here is yttrium in blue.

Needing stronger magnetic fields, compact tokamaks require a superconducting material with an even higher irreversibility field. Over the last decade, another class of superconducting materials called “REBCO” have been proposed as an alternative. Short for rare earth barium copper oxide, these are a family of superconductors with the chemical formula REBa2Cu3O7, where RE is a rare-earth element such as yttrium, gadolinium or europium (see Box 2 “REBCO unit cell”).

REBCO compounds are high-temperature superconductors, which are defined as having transition temperatures above 77 K, meaning they can be cooled with liquid nitrogen rather than the more expensive liquid helium. REBCO compounds also have a much higher irreversibility field than niobium-tin, and so can sustain the high fields necessary for a small fusion reactor.

REBCO wires: Bendy but brittle

REBCO materials have attractive superconducting properties, but it is not easy to manufacture them into flexible wires for electromagnets. REBCO is a brittle ceramic so can’t be made into wires in the same way as ductile materials like copper or Nb-Ti, where the material is drawn through progressively smaller holes.

Instead, REBCO tapes are manufactured by coating metallic ribbons with a series of very thin ceramic layers, one of which is the superconducting REBCO compound. Ideally, the REBCO would be a single crystal, but in practice, it will be comprised of many small grains. The metal gives mechanical stability and flexibility whilst the underlying ceramic “buffer” layers protect the REBCO from chemical reactions with the metal and act as a template for aligning the REBCO grains. This is important because the boundaries between individual grains reduce the maximum current the wire can carry.

Another potential problem is that these compounds are chemically sensitive and are “poisoned” by nearly all the impurities that may be introduced during manufacture. These impurities can produce insulating compounds that block supercurrent flow or degrade the performance of the REBCO compound itself.

Despite these challenges, and thanks to impressive materials engineering from several companies and institutions worldwide, REBCO is now made in kilometre-long, flexible tapes capable of carrying thousands of amps of current. In 2024, more than 10,000 km of this material was manufactured for the burgeoning fusion industry. This is impressive given that only 1000 km was made in 2020. However, a single compact tokamak will require up to 20,000 km of this REBCO-coated conductor for the magnet systems, and because the superconductor is so expensive to manufacture it is estimated that this would account for a considerable fraction of the total cost of a power plant.

Pushing superconductors to the limit

Another problem with REBCO materials is that the temperature below which they superconduct falls steeply once they’ve been irradiated with neutrons. Their lifetime in service will depend on the reactor design and amount of shielding, but research from the Vienna University of Technology in 2018 suggested that REBCO materials can withstand about a thousand times less damage than structural materials like steel before they start to lose performance (Supercond. Sci. Technol. 31 044006).

These experiments are currently being used by the designers of small fusion machines to assess how much shielding will be required, but they don’t tell the whole story. The 2018 study used neutrons from a fission reactor, which have a different spectrum of energies compared to fusion neutrons. They also did not reproduce the environment inside a compact tokamak, where the superconducting tapes will be at cryogenic temperatures, carrying high currents and under considerable strain from Lorentz forces generated in the magnets.

Even if we could get a sample of REBCO inside a working tokamak, the maximum runtime of current machines is measured in minutes, meaning we cannot do enough damage to test how susceptible the superconductor will be in a real fusion environment. The current record for tokamak power is 69 megajoules, achieved in a 5-second burst at the Joint European Torus (JET) tokamak in the UK.

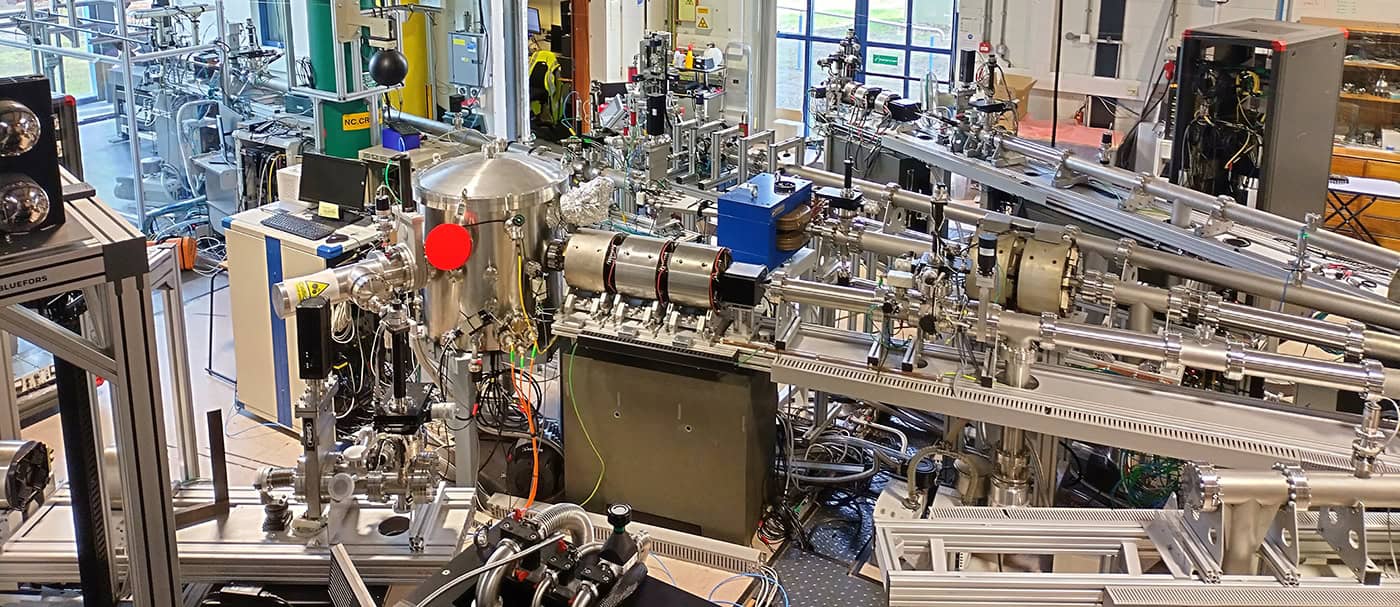

Given the difficulty of using neutrons from fusion reactors, our team is looking for answers using ions instead. Ion irradiation is much more readily available, quicker to perform, and doesn’t make the samples radioactive. It is also possible to access a wide range of energies and ion species to tune the damage mechanisms in the material. The trouble is that because ions are charged they won’t interact with materials in exactly the same way as neutrons, so it is not clear if these particles cause the same kinds of damage or by the same mechanisms.

To find out, we first tried to directly image the crystalline structure of REBCO after both neutron and ion irradiation using transmission electron microscopy (TEM). When we compared the samples, we saw small amorphous regions in the neutron-irradiated REBCO where the crystal structure was destroyed (J. Microsc. 286 3), which are not observed after light ion irradiation (see Box 3 below).

3 Spot the difference

TEM images of REBCO before (a) and after (b) helium ion irradiation. The image on the right (c) shows only the positions of the copper, barium and rare-earth atoms – the oxygen atoms in the crystal lattice cannot be inages using this technique. After ion irradiation, REBCO materials exhibit a lower superconducting transition temperature. However, the above images show no corresponding defects in the lattice, indicating that defects caused by oxygen atoms being knocked out of place are responsible for this effect.

We believe these regions to be collision cascades generated initially by a single violent neutron impact that knocks an atom out of its place in the lattice with enough energy that the atom ricochets through the material, knocking other atoms from their positions. However, these amorphous regions are small, and superconducting currents should be able to pass around them, so it was likely that another effect was reducing the superconducting transition temperature.

Searching for clues

The TEM images didn’t show any other defects, so on our hunt to understand the effect of neutron irradiation, we instead thought about what we couldn’t see in the images. The TEM technique we used cannot resolve the oxygen atoms in REBCO because they are too light to scatter the electrons by large angles. Oxygen is also the most mobile atom in a REBCO material, which led us to think that oxygen point defects – single oxygen atoms that have been moved out of place and which are distributed randomly throughout the material – might be responsible for the drop in transition temperature.

In REBCO, the oxygen atoms are all bonded to copper, so the bonding environment of the copper atoms can be used to identify oxygen defects. To test this theory we switched from electrons to photons, using a technique called X-ray absorption spectroscopy. Here the sample is illuminated with X-rays that preferentially excite the copper atoms; the precise energies where absorption is highest indicate specific bonding arrangements, and therefore point to specific defects. We have started to identify the defects that are likely to be present in the irradiated samples, finding spectral changes that are consistent with oxygen atoms moving into unoccupied sites (Communications Materials 3 52).

We see very similar changes to the spectra when we irradiate with helium ions and neutrons, suggesting that similar defects are created in both cases (Supercond. Sci. Technol. 36 10LT01 ). This work has increased our confidence that light ions are a good proxy for neutron damage in REBCO superconductors, and that this damage is due to changes in the oxygen lattice.

Another advantage of ion irradiation is that, compared to neutrons, it is easier to access experimentally relevant cryogenic temperatures. Our experiments are performed at the Surrey Ion Beam Centre, where a cryocooler can be attached to the end of the ion accelerator, enabling us to recreate some of the conditions inside a fusion reactor.

We have shown that when REBCO is irradiated at cryogenic temperatures and then allowed to warm to room temperature, it recovers some of its superconducting properties (Supercond. Sci. Technol. 34 09LT01). We attribute this to annealing, where rearrangements of atoms occur in a material warmed below its melting point, smoothing out defects in the crystal lattice. We have shown that further recovery of a perfect superconducting lattice can be induced using careful heat treatments to avoid loss of oxygen from the samples (MRS Bulletin 48 710).

Lots more experiments are required to fully understand the effect of irradiation temperature on the degradation of REBCO. Our results indicate that room temperature and cryogenic irradiation with helium ions lead to a similar rate of degradation, but similar work by a group at the Massachusetts Institute of Technology (MIT) in the US using proton irradiation has found that the superconductor degrades more rapidly at cryogenic temperatures (Rev. Sci. Instrum. 95 063907). The effect of other critical parameters like magnetic field and strain also still needs to be explored.

Towards net zero

The remarkable properties of REBCO high-temperature superconductors present new opportunities for designing fusion reactors that are substantially smaller (and cheaper) than traditional tokamaks, and which private companies ambitiously promise will enable the delivery of power to the grid on vastly accelerated timescales. REBCO tape can already be manufactured commercially with the required performance but more research is needed to understand the effects of neutron damage that the magnets will be subjected to so they will achieve the desired service lifetimes.

This would open up extensive new applications, such as lossless transmission cables, wind turbine generators and magnet-based energy storage devices

Scale-up of REBCO tape production is already happening at pace, and it is expected that this will drive down the cost of manufacture. This would open up extensive new applications, not only in fusion but also in power applications such as lossless transmission cables, for which the historically high costs of the superconducting material have proved prohibitive. Superconductors are also being introduced into wind turbine generators, and magnet-based energy storage devices.

This symbiotic relationship between fusion and superconductor research could lead not only to the realization of clean fusion energy but also many other superconducting technologies that will contribute to the achievement of net zero.