Rydberg Vacuum Sciences provides a core enabling technology to support the development and prelaunch validation of small-satellite systems

Space, it seems, is no longer the final frontier that it used to be. The emergence of small satellites – broadly, instruments with a mass ranging from 1 to 500 kg – has, in large part, levelled the playing field in the space industry over the past two decades. Agile start-up companies, established manufacturers and even university research groups are all now in a position to compete with the big-budget missions of government space agencies – opening up commercial and scientific opportunities in applications as diverse as remote sensing, environmental protection, asset tracking and logistics, and machine-to-machine communication for the “Internet of Things”.

The upward trajectory is clear to see: the evolution of small-satellite technologies will continue apace, squeezing more and more functionality into ever-decreasing payloads while further lowering the barriers to entry for new-entrants to the space industry. All of which translates into relentless downward pressure on the capital/operational spend of satellite developers and their engineering teams – not least when it comes to the exacting test programmes needed to qualify satellite systems for launch and, ultimately, long-term operation in orbit.

Vacuum versatility

With this in mind, US start-up Rydberg Vacuum Sciences (RVS) is busy establishing itself as a “go-to” equipment provider in the emerging test-and-measurement ecosystem serving the small-satellite community. More precisely, RVS is targeting a specialist niche in the preflight qualification workflow for small satellites and their constituent systems: the provision of affordable, off-the-shelf thermal vacuum bake-out and thermal vacuum cycling products.

“I see RVS as a direct response to the democratization of the satellite launch industry,” explains Joshua Gurian, founder and president of the Seattle-based test-and-measurement specialist. “Right now, we’re seeing more orders from private-sector entrants to the space industry, though it’s worth noting that the long-term goal is also to make our ‘drop-in-place’ test solutions accessible to burgeoning small-satellite R&D initiatives within North American universities and further afield.”

That twin-track approach is already evident. Last year, for example, RVS supplied two thermal vacuum test systems to AST&Science, which is developing a space-based cellular broadband network (SpaceMobile) to provide 4G/5G connectivity to smartphones anywhere on the planet. “We’ve shipped to AST&Science facilities in Texas and Israel, where they’re testing fold-out solar panels for their SpaceMobile satellite constellation,” says Gurian. “Another three test systems are on their way to the Space Dynamics Laboratory at Utah State University, which is looking to increase its small-satellite testing capacity for both in-house and for-hire projects.”

Passing the test

For satellite developers big and small, there are no short-cuts into orbit. Consider the thermal vacuum test programme for any small-satellite project: it’s an exhaustive undertaking that requires granular evaluation at the component, subsystem and system level. A thermal vacuum cycling test, for example, will see the craft’s hardware and instrumentation put through its paces and subjected to a “step-and-repeat” programme of extreme hot and cold temperatures in a high-vacuum environment, while a thermal balance test aims to demonstrate the effectiveness of the craft’s thermal control systems for maintaining the temperature of key systems within predefined limits. There’s also a vacuum bake-out requirement, in which the satellite hardware is heated to high temperature under high vacuum to quantify levels of material outgassing (the products of which can adversely affect the performance of on-board imaging systems, thermal radiators, solar cells and the like).

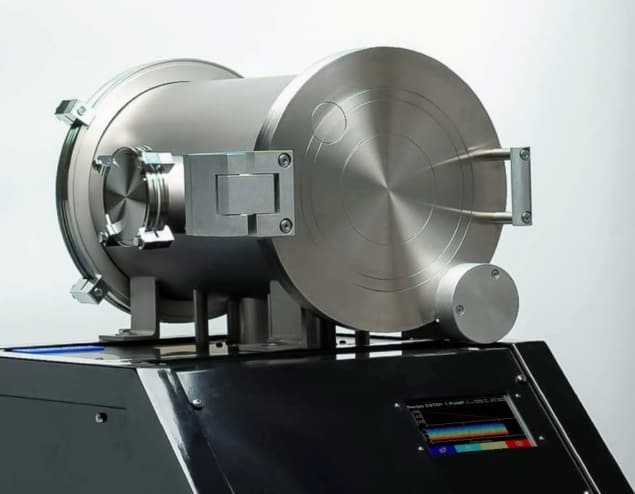

“Although the detail of the vacuum test programme is generally dictated by the satellite launch provider,” notes Gurian, “we have a lot of technical domain knowledge here at RVS to support our research and industry customers.” Equally, the RVS emphasis on off-the-shelf vacuum systems provides thermal testing at a palatable price-point for any developer seeking to launch inexpensive small satellites. “Ease-of-use is paramount,” Gurian adds. “With a footprint of just 0.6×1.2 m, installing an RVS thermal vacuum system is as simple as unpacking the crate and connecting the utilities.”

Modelling vs real-world measurement

As part of the prelaunch test programme, a satellite developer will typically generate a model of the temperature extremes the craft is likely to experience once it’s in orbit and traversing from day to night on the dark side of the Earth. Trouble is, many satellite subsystems – for example, battery packs and on-board cameras – are not optimized to handle the environmental extremes encountered in orbit. As such, thermal vacuum testing is essential to validate the modelling and to ensure that any localized heating/cooling units are having the desired effect.

A typical thermal vacuum cycling test might look something like this: an engineer first pumps the test chamber down to high vacuum (say 10-6 mbar) before taking the unit under test (UUT) up to Tmax – ramping at roughly 3 °C/min to 100 °C, for example. After which the UUT will undergo a “soak” for typically 4 h (but anywhere from 1–24 h) at Tmax, before cycling down for another extended soak at Tmin (at –100 °C), before a gradual ramp again to Tmax. “The whole step-and-repeat programme is often run more than 10 times over a period of several days, after which the UUT is brought back to room temperature to make sure that everything is still working to specification,” adds Gurian.

For RVS, the task is to provide the vacuum infrastructure to support this test-and-measurement workflow, helping customers to ensure that their small-satellite components/subsystems are fit-for-purpose and guaranteed for long-term survivability in orbit. “The thermal test regime generates lots of data – there are thermocouples slapped all over the UUT,” concludes Gurian. “Those data allow the user to compare the actual thermal performance of the UUT versus the modelled behaviour and to make mission-critical design adjustments ahead of launch.”

- RVS will be exhibiting at the 35th Annual Small Satellite Conference at Utah State University (7–12 August 2021).

Hot stuff: thermal vacuum testing

The RVS line of small-satellite test systems provides a “drop-in-place” solution for compliance with GSFC-STD-7000 or MIL-STD-1540 test standards. Key specifications include…

- Operational performance: atmospheric pressure to high vacuum in <30 min; temperature range –150 °C to +150 °C; controllable ramp rate up to 5 °C/min

- A 6U vacuum test volume (370×240×120 mm)

- Turbomolecular pump (300 l/s) backed by a frame-integrated dry Roots pump

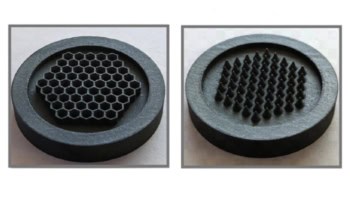

- Temperature-controlled platen with 50×50 mm M6 grid for UUT fixturing and integrated thermal radiation shielding

- Two blank ISO-100LF user ports for pass-through of electrical/instrumentation cabling and gas lines as required

- Optional accessories include: residual gas analyser (100–300 amu); optical witness sample holder; and temperature-controlled quartz-crystal microbalance.

Standard vacuum test systems ship in 8–10 weeks, with rental options also available for customers requiring a short-term testing capability.