Researchers have made high-performance thick organic light-emitting diodes (OLEDs) by combining organic thin films and organic-inorganic perovskite transport layers. The materials, which have the same light-emitting efficiencies as reference thin OLEDs, could be used to make affordable displays and screens that emit the same colour from all viewing angles.

OLEDs make use of layers of organic molecules to efficiently convert electricity into light. The organic layers are placed between two electrodes, one of which is usually transparent. They are ideal for applications in next-generation displays and lighting but the problem is that they need to be made as thin as around 100 nm. This is because organic molecules, while being excellent emitters of light, are generally poor conductors. Only such thin layers can carry electricity to the central, active light-emitting part of a device.

The drawback of thin layers is that they cannot completely cover defects and residues on a substrate. These defects produce shunting paths between the electrodes. Shunting paths are a nuisance since it is through these that charge carriers bypass the organic layers without recombining to produce light. This leads to low efficiency or even complete device failure in the case of electrical shorts. What is more, light that is reflected between the front and back of the thin layers produces cavity effects that can distort the emission colour at large viewing angles.

Making thicker films

Thicker organic transport layers are a possible solution to this problem, but the thicker the layer, the higher the driving voltage needs to be.

Although researchers have tried to make thick OLEDs using organic single crystals, these cannot be mass produced. They have also tried chemically doping the organic layers to increase their electrical conductivity, but additional light absorption bands that reduce electroluminescence efficiency appear in the materials.

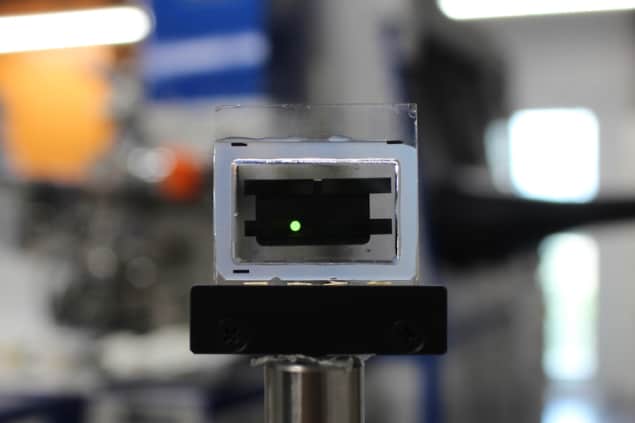

A team from Kyushu University in Japan says that it may now have found an answer to this challenge – by using the organic-inorganic perovskite methylammonium lead chloride, CH3NH3PbCl3 (MAPbCl3), instead of organic molecules as the transport layer. In their devices, the researchers sandwiched a layer of light-emitting molecules typically employed in OLEDs between the perovskite layers. They were thus able to increase the total thickness of the active MAPbCl3 layers to 2000 nm, which is more than 10 times the thickness of standard OLEDs, without the need for high driving voltages.

The films also have a low surface roughness, which means that they can better cover a substrate and supress the formation of the dreaded shunting paths. They do not absorb light in the visible region either, which is why they can be used to make thicker OLEDs without affecting the internal electroluminescence quantum efficiency.

Thanks to X-ray diffraction patterns and absorption spectra of the films, the researchers also confirmed that the films are stable in air even after 11 days. Another non-negligible advantage, they say, is that OLEDs made using these films could be cheaper because they cost less than organic materials do.

Tokyo’s Nanotech Week offers a glimpse of the future

Overturning 30 years of thinking

Until now, researchers have mainly employed perovskites, which have an ABX3 structure, where A is caesium and methylammonium (MA) or formamidinium (FA), B is lead or tin and X is chlorine, bromine or iodine, as light emitters. This is because they can absorb light over a broad range of solar spectrum wavelengths thanks to their tunable bandgaps. In this work, however, the Japan team has used them for just transporting electricity – they are good in this respect too since charge carriers can diffuse through them quickly and over long lengths – and kept the organic molecules for the light emission part. In this way, it was able to produce thick devices that have the same light emitting efficiencies as reference thin OLEDs.

“These results overturn 30 years of thinking that OLEDs are limited to thin films and open new paths for low-cost, reliable and uniform fabrication of OLED-based displays and lighting,” says team leader Chihaya Adachi. “Based on this work, perovskites will be seen in a new light as versatile, high-performance materials for supporting roles in not only OLEDs but also other organic electronic devices, such as lasers, memory devices, and sensors.”

The thick OLEDs are described in Nature 10.1038/s41586-019-1435-5.