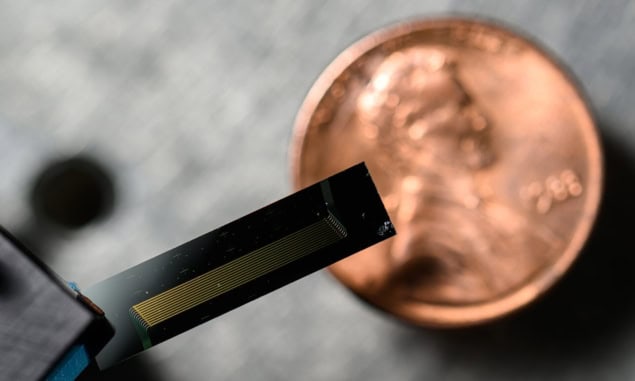

A new solid-state laser can make a vast number of precise optical measurements each second, while sweeping across a broad range of optical wavelengths. Created by a team led by Qiang Lin at the University of Rochester in the US, the device can be fully integrated onto a single chip.

Optical metrology is a highly versatile technique that uses light to gather information about the physical properties of target objects. It involves illuminating a sample and measuring the results with great precision – using techniques such as interferometry and spectroscopy. In the 1960s, the introduction of lasers and the coherent light they emit boosted the technique to an unprecedented level of precision. This paved the way for advances ranging from optical clocks, to the detection of gravitational waves.

Yet despite the indispensable role they have played so far, lasers have also created a difficult challenge. To ensure the best possible precision, experimentalists much achieve very tight control over the wavelength, phase, polarization and other properties of the laser light. This is very difficult to do within the tiny solid-state laser diodes that are very useful in metrology.

Currently, the light from laser diodes is improved externally using optical modules. This added infrastructure is inherently bulky and it remains difficult to integrate the entire setup onto chip-scale components – which limits the development of small, fast lasers for metrology.

Two innovations

Lin and colleagues addressed this challenge by designing a new laser with two key components. One is a laser cavity that comprises a thin film of lithium niobate. Thanks to the Pockels effect, this material’s refractive index can vary depending on the strength of an applied electric field. This provides control over the wavelength of the light amplified by the cavity.

The other component is a distributed Bragg reflector (DBR), which is a structure containing periodic grooves that create alternating regions of refractive index. With the right spacing of these grooves, a DBR can strongly reflect light at a single, narrow linewidth, while scattering all other wavelengths. In previous studies, lasers were created by etching a DBR directly onto a lithium niobate film – but due to the material’s optical properties, this resulted in a broad linewidth.

“Instead, we developed an ‘extended DBR’ structure, where the Bragg grating is defined in a silica cladding,” explains team member Mingxiao Li at the University of California Santa Barbara. “This allowed for flexible control over the grating strength, via the thickness and etch depth of the cladding. It also leverages silica’s superior etchability to achieve low scattering strength, which is essential for narrow linewidth operation.”

Using a system of integrated electrodes, Lin’s team can adjust the strength of the electric field they applied to the lithium niobate film. This allows them to rapidly tune the wavelengths amplified by the cavity via the Pockels effect. In addition, they used a specially designed waveguide to control the phase of light passing into the cavity. This design enabled them to tune their laser over a broad range of wavelengths, without needing external correction modules to achieve narrow linewidths.

Narrowband performance

Altogether, the laser demonstrated an outstanding performance on a single chip – producing a clean, single wavelength with very little noise. Most importantly, the light had a linewidth of just 167 Hz – the smallest range achieved to date for a single-chip lithium niobate laser. This exceptional performance enabled the laser to rapidly sweep across a bandwidth of over 10 GHz – equivalent to scanning quintillions of points per second.

New titanium:sapphire laser is tiny, low-cost and tuneable

“These capabilities translated directly into successful applications,” Li describes. “The laser served as the core light source in a high-speed LIDAR system, measuring the velocity of a target 0.4 m away with better than 2 cm distance resolution. The system supports a velocity measurement as high as Earth’s orbital velocity – around 7.91 km/s – at 1 m.” Furthermore, Lin’s team were able to lock their laser’s frequency with a reference gas cell, integrated directly onto the same chip.

By eliminating the need for bulky control modules, the team’s design could now pave the way for the full miniaturization of optical metrology – with immediate benefits for technologies including optical clocks, quantum computers, self-driving vehicles, and many others.

“Beyond these, the laser’s core advantages – exceptional coherence, multifunctional control, and scalable fabrication – position it as a versatile platform for transformative advances in high-speed communications, ultra-precise frequency generation, and microwave photonics,” Lin says.

The new laser is described in Light: Science & Applications.