A new type of flat, ultrathin lens designed to be free of chromatic aberrations has been developed by researchers in the US. The device has a variety of potential applications, from ultralight imaging systems for drone aircraft to more compact lenses for mobile-phone cameras.

Lenses for cameras, eyeglasses and other applications are traditionally based on refractive optics, which involves using curved lenses to bend light rays. The “optical power” of a conventional lens – how strongly it bends light – is proportional to its thickness, which means that a conventional refractive lens cannot be very thin. Refractive lenses also suffer from chromatic dispersion, wherein blue light bends more than red, and therefore multiple images are produced over a range of focal lengths. Multiple lenses can cancel out this dispersion, but this adds further to the weight, thickness and cost of a lens system.

Diffractive lenses offer a route to ultrathin lenses by redirecting light using the interference between light waves as they pass through a series of slits in a thin opaque material. Such lenses can be effectively flat, and therefore much lighter and thinner than refractive optics. However, diffractive lenses suffer from much larger dispersion. And to further complicate matters, this dispersion is anomalous with red light bending more than blue.

Thin metasurface

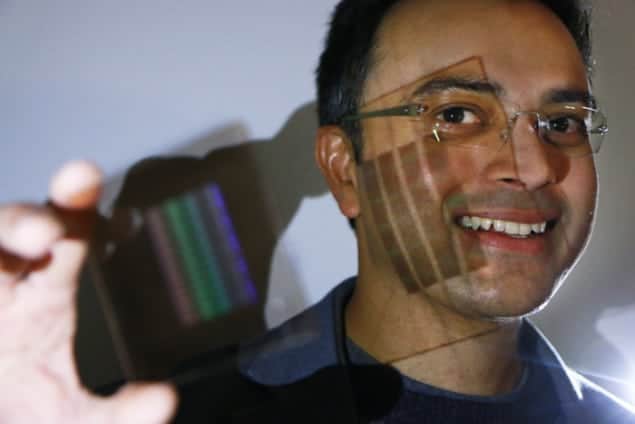

In 2015 Federico Capasso of Harvard University and colleagues showed that a flat lens can be made that focuses all of the colours of broadband light in the same plane. The team then unveiled a device that focused broadband infrared light onto a single line using a thin metasurface.

To be used in a camera, you need to be able to form good images, and that will require a little bit more work

Rajesh Menon, University of Utah

This device used dielectric resonators that interact directly with the electromagnetic field of light waves to impart any desired phase shift. However, this new technology brings its own challenges. Making the metasurfaces requires precision engineering because the resonators have to be smaller than the wavelength of the focussed light. Metasurfaces are also inherently polarization-sensitive, whereas a general-purpose camera lens needs to focus unpolarized light.

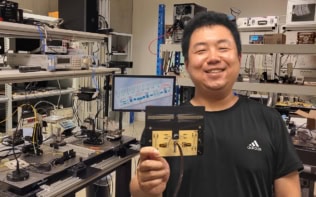

Now, Rajesh Menon of the University of Utah and colleagues have focused broadband visible light using a different approach that involves creating a series of grooves in a soda-lime glass surface. The height and width of each groove was selected using a computer algorithm that optimized focusing across the entire visible spectrum. This involved using the conventional dispersion of the glass material to compensate for the anomalous dispersion of the grating, such that waves would be focused on the same line irrespective of wavelength.

Less precision needed

To test their device, the researchers illuminated the lens with light at variable wavelengths, measuring the distances at which light of different wavelengths was focused. The difference was comparable with commercial “achromatic” refractive lenses, and rotating the polarization of the light made no detectable difference. Furthermore, creating the patterned surface does not require the same degree of precision engineering as resonators. The smallest feature size on the glass surface was 3 μm, whereas the researchers calculated that a metasurface to do the same job would need resonators just 39 nm in size.

Menon and colleagues are now working to develop their lens further. “What we have shown is only one function of the lens – focusing,” Menon says. “To be used in a camera, you need to be able to form good images, and that will require a little bit more work.”

“Both [Menon and Capasso] have contributed to an important advance in making diffractive lenses a practical proposition for broadband applications,” says John Pendry of Imperial College London. Pendry suspects the costs associated with mass production of Capasso’s design might be manageable. “The technologies used for making chips can get down to that sort of resolution for volume production,” he says. “Performance would be a better metric for comparison. It remains to be seen which solution wins in practical terms.”

The lens is described in Scientific Reports.