The European Synchrotron Radiation Facility’s first online User Meeting will allow attendees from all over the world to explore the technical and scientific capabilities of the new Extremely Brilliant Source

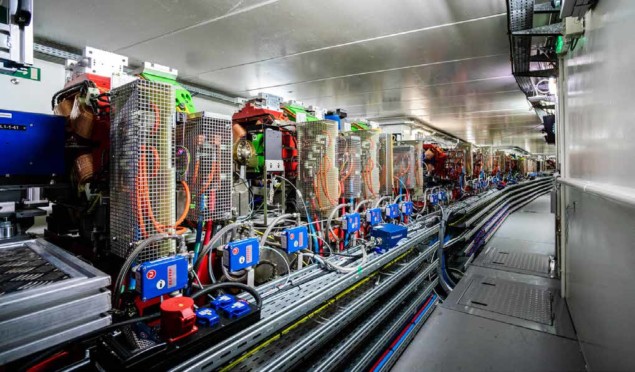

In August 2020 the European Synchrotron Radiation Facility (ESRF) in Grenoble, France, unveiled the world’s brightest source of high-energy X-rays. An extensive upgrade costing €150m has transformed the facility into the Extremely Brilliant Source, or ESRF–EBS, a fourth-generation synchrotron that boosts the brilliance and coherence of the X-ray beams by around a factor of 100 over its predecessor.

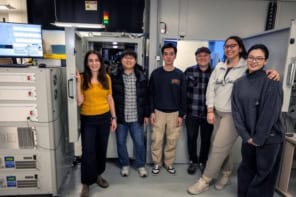

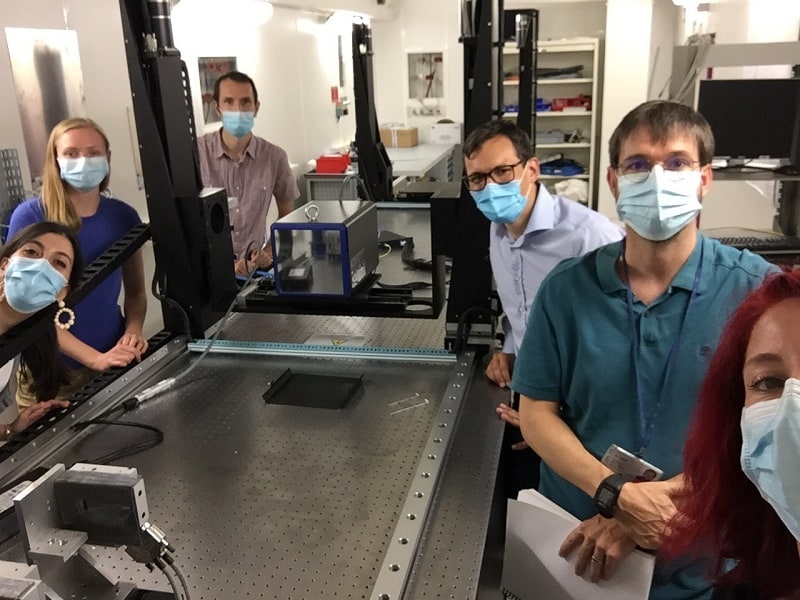

Scientists from around the world started to use the machine on 25 August, for the moment via remote experiments, with the upgraded machine making it possible to study the structure of matter at the atomic level much faster and in greater detail than before. At this year’s ESRF User Meeting, a virtual event that will run from 8–10 February, attendees will be able to explore the technical capabilities of the ESRF–EBS as well as the new science it will enable.

Normally held at the ESRF, this year’s online event will enable scientists in all parts of the world to take part in tutorials, poster sessions and scientific symposia, and to interact with each other remotely to discuss new research ideas. A plenary session on Tuesday 9 February will feature five keynote lectures on different applications of synchrotron science – including industrial catalysis and research into the pathology of the COVID-19 virus – as well as a facility update on the ESRF-EBS.

Suppliers to the ESRF will be taking part in a virtual commercial exhibition, and have also been working closely with the ESRF’s technical teams to deliver solutions that meet the needs of next-generation synchrotrons as well as other major scientific projects. A few examples are highlighted below.

Fast detectors deliver precision for high-energy applications

DECTRIS, which specializes in producing high-performance hybrid photon-counting X-ray detectors, has developed two models for high-energy applications in next-generation synchrotron sources. The EIGER2 X and XE CdTe detectors combine high performance with easy integration and operation, and are equipped with a cadmium-telluride sensor to provide high quantum efficiencies for hard X-ray energies up to 100 keV. With a pixel size of just 75 mm, they also provide excellent spatial resolution.

The detectors’ readout eliminates any dead time, which ensures that no photons are lost between frames. Two adjustable energy thresholds make it possible to simultaneously determine the fluorescence background (the lower threshold) while also measuring the contribution of higher harmonics (the upper threshold). With a one-pixel-point spread function (PSF) and a count-rate capability of 107 photons/s per pixel, the EIGER2 X and XE CdTe detectors deliver more precise measurements than ever before.

Different versions of the detectors are available, with active areas ranging from 77 x 38 mm2 to 311 x 327 mm2. The smallest detectors in the EIGER2 X series offer frame rates of 2 kHz, while the XE versions have been optimized to combine a large active area with a frame rate of up to 550 Hz – ideal for applications such as macromolecular crystallography, materials science, and small-angle X-ray scattering. In addition, both versions have been designed to deliver high efficiency at high energies, yielding the best possible resolution and frame rate for next-generation synchrotrons.

The ESRF, as part of its EBS upgrade, has received eight EIGER2 detectors that are being taken into operation. “The combination of the extremely brilliant source and the high dynamic range and high sensitivity of the EIGER2 CdTe detector will allow us to detect weak features in diffraction data,” says beamline scientist Carlotta Giacobbe. “Ultrafast 3D mapping and ultra-fine slicing will now be accessible for monitoring systems as they evolve during in situ experiments”.

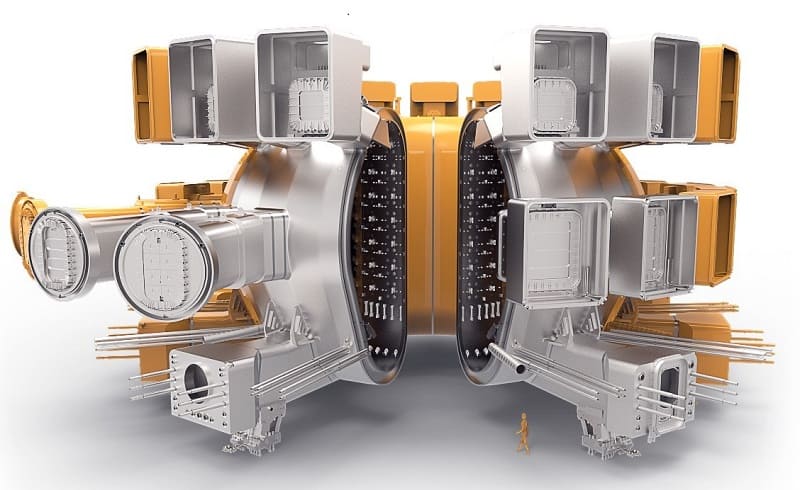

ITER sets new challenges for leak detection

40-30, a French company that specializes in process and vacuum technologies for large engineering projects, has been a long-time supplier to the ESRF and other major experimental facilities. That includes ITER, the fusion reactor now being built in Cadarache in the south of France, where 40-30 is part of a consortium designing and building one of the most complex leak detection systems in the world.

Achieving and maintaining the right conditions for the fusion reaction between deuterium and tritium requires the vacuum vessel that contains the plasma, along with the 14,000 m3 cryostat and other core components, to be kept under ultrahigh-vacuum conditions. Any leaks or contamination must be detected as soon as possible, but that’s a challenging task when there are around 2000 entry points to the overall system.

“We spent a whole year working out the basic functional requirements of the leak detection systems for ITER, and translating them into technical specifications and contract documentation,” says Roger Martín, the project manager at Fusion for Energy (F4E) who was responsible for procuring the detection system.

The resulting design is a series of helium leak-detection subsystems that exploit high-resolution mass spectrometry to detect helium ingress under specific conditions – including a high-radiation environment with strong magnetic fields, complying with the nuclear safety standards applying to ITER, and even the possibility of seismic activity. Although mass spectrometry is widely used for leak detection, adapting the technology to ITER standards is particularly demanding.

After an extensive tendering process, the €17 m contract for delivering the leak-detection system was awarded to the IG4 consortium, led by Spanish engineering consultants IDOM. 40-30 will be responsible for process and vacuum engineering, as well as equipment specification, while Gutmar will manufacture, assemble and test the equipment.

“We are really proud to be involved in this project,” says Charles Agnetti, CEO of 40-30. “For this mission, 40-30 has assigned its most experienced specialists in vacuum technology and processes, leak detection and gas analysis.” It will take more than three years to deliver the project, with a preliminary design review due in the first half of 2021.

Compact LAMBDA detectors shrink even further

X-Spectrum GmbH specializes in developing high-resolution and high-speed X-ray detectors built around the Medipix3 RX detector chips, originally developed by CERN. The workhorse among the company’s line-up is the LAMBDA 750k, one of the most compact X-ray detectors on the market. In the latest development, the well-known wedge-shaped case of the LAMBDA 750k has been redesigned to create an even more compact box that measures just 235 x 100 x 42 mm3 – about half the length and height of the previous version.

The X-Spectrum engineers have worked hard to develop an efficient cooling system that fits inside this very small package. That will enable users to install the LAMBDA 750k X-ray in even the most crowded beamlines and tight experimental set-ups.

The LAMBDA 750k is one version of a family of next-generation pixel detectors for X-rays, all based on Medipix3 technology. The LAMBDA series are photon-counting detectors, effectively making them noise free, and offer speeds of up to 23,000 frames per second (with no readout dead-time) along with a small pixel size of 55 µm. A variety of sizes and configurations are available for different applications, and each one can be equipped with different sensor materials to allow high detection efficiency even at high X-ray energies.

The LAMBDA system also has “colour imaging” capabilities, where X-rays hitting the detector can be divided into two energy ranges. Originally developed by DESY in Hamburg, Germany, for use at the PETRA-III synchrotron, the system is designed for high reliability, and has external triggering and gating capability for synchronization with the rest of the experiment. It can also be easily integrated into common beamline control systems.