A metallic water solution has been observed in the laboratory for the first time thanks to a new method that bypasses the need for extremely high pressures. By reacting water with an alkali metal in a way that avoids the usual explosive outcome, an international team of researchers showed that they could produce a gold-coloured conducting layer on the surface of the resulting solution – a rare example of a modern scientific result visible to the naked eye.

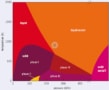

In principle, any insulating material can be transformed into a metal by applying a high enough pressure to it. For pure water, the pressure required is 48 megabars – a value that is way beyond what is possible in laboratory experiments and may be literally astronomical, existing only inside the cores of large planets or stars.

At pressures obtainable in the laboratory, researchers recently showed that water could be made superionic, containing high-conductivity protons. A metallic state containing conductive electrons, however, was thought to be out of reach.

Suppressing explosions

Researchers led by Pavel Jungwirth have now turned this idea on its head by reacting water with a sodium-potassium (NaK) alloy to produce a metallic water solution. To do this, they first had to suppress the explosive reaction – a favourite of school science experiments – that normally occurs when water and an alkali metal come together.

“We know that dissolving alkali metals in water leads to explosions, so we did it the other way around,” Jungwirth says. “We blew a tiny amount of water at pressures as low as 10-4 mbar onto a NaK alloy drop squirted from a micronozzle at a dripping rate of about one drop every 10 s in vacuum.”

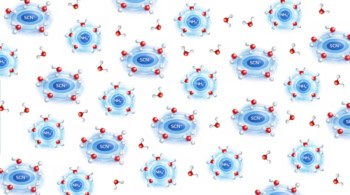

When there is no water vapour in the vacuum chamber, the NaK drops have a silver metallic sheen. This lack of visible colour occurs because alkali metals do not have d or f electrons that can be optically excited and produce colour via photoluminescence. When the researchers introduced water into the chamber, Jungwirth says they were “lucky enough” to find a water vapour pressure (~10-4 mbar) at which roughly 100-nm-thick layers of water begin to form on the alkali metal drop. At this pressure, the underlying alkali metal layer dissolves faster than the metal and water can react, forming a metallic water solution.

Surface layer turns golden

Once enough water adsorbs to the surface of the NaK drops, the researchers report that the surface layer turns gold almost immediately and remains in that condition for up to ~5 s. After this point, as water continues to adsorb, the drop’s colour changes to bronze for another 2−3 s. Eventually, the drop loses its metallic sheen, turning purple/blue and finally white as an alkali hydroxide layer forms as a product of the alkali metal-water reaction.

The whole process lasts for about 10 s, during which time the drop grows and reaches its final size of ~5 mm in diameter. It then falls off the end of the nozzle and a new drop starts to grow. This process can continue for a “train” of hundreds of drops, provided the water vapour pressure remains in a relatively narrow range around its optimal value. The trick, Jungwirth says, is to use only a tiny amount of water and go directly to the concentrated metallic regime. It also helps that the delocalized (metallic) electrons are less reactive than the localized solvated electrons.

Black metal hydrogen emerges at high pressures

Concentrated metallic regime

The researchers used optical and photoelectron spectroscopy techniques to characterize the metallic nature of the drop’s surface layer. They estimate that this layer contains around 5 × 1021 electrons per cubic centimetre. While the practical applications of creating a 100-nm-layer of metallic water that lasts for a few seconds are most likely zero, Jungwirth notes that the experiment is “really beautiful” and easy to follow. “My hope is that if a smart high school kid sees this, they may decide to study physics or chemistry,” he tells Physics World.

The researchers, who report their work in Nature, say they now plan to map in detail the metal-to-electrolyte transition upon diluting the metallic water layer with more water, as they did for metallic ammonia last year.