As any child knows, the best way to build a sandcastle is to use wet sand because it sticks together nicely, whereas a castle made from dry sand will collapse under its own weight. Now, however, physicists in Germany have turned this law of the playground on its head by showing that — under some circumstances at least — wet sand can flow better than the dry stuff.

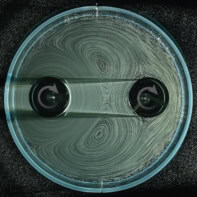

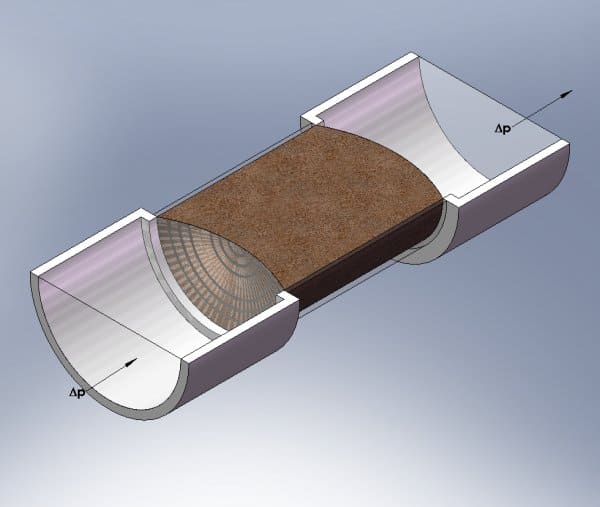

Christian Wagner and colleagues at the University of Saarland came to this surprising conclusion after measuring the force needed to push an idealized form of sand through a circular tube (arXiv:0711.2972v1). The “sand” consisted of an aqueous slurry of tiny glass beads with a diameter of 145 microns, which is roughly that of a grain of sand. The researchers found that less energy was required to push sand through the tube if it was wet than if it was dry.

Dry sand usually flows freely because air voids can form between the grains, which keeps them apart and reduces friction. But when the sand is packed in a tube, there is no room for voids to occur and therefore air cannot lubricate the flow. As a result, friction causes the dry sand to jam.

If the sand in the tube is wet, the water initially acts like glue, causing individual grains to bind together, just as in a sandcastle. But if sufficient force is applied, the bonds between grains are broken and the water acts as a lubricant, causing the sand to flow more easily. The team was able to see this happen by measuring the movement of the sand as it was subjected to an increasing force.

According to Wagner, wet sand is an example of a “yield stress” fluid, which — like toothpaste — will begin to flow only when sufficient force is exerted on it. Wagner believes that their study should provide a better understanding of some industrial processes involving the movement of granular materials.

Although the wet sand used in the experiment contained about 3% water by volume — less than for wet sand on a beach — Wagner believes that the ideal sand for sandcastles should also behave as a yield stress fluid.