Welcome to the first in a new series of sponsored articles showcasing some of the latest white papers from physics-based businesses around the world

This time we are featuring white papers from three firms: Bruker Nano, Dectris and Park Systems. You can access the content by following the link in the name of the relevant white paper.

Material properties

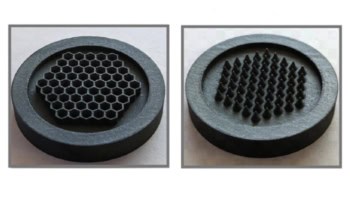

Bruker is showcasing two white papers. The first is on surface roughness, which is widely used in industry to validate manufacturing processes and guarantee the quality of products. Subjective judgements of quality, which you can obtain by looking at the surface of a product with your naked eye or feeling it with your finger, have steadily been replaced by unbiased metrics and well-defined formulas. In Advantages of Measuring Surface Roughness with White Light Interferometry, Samuel Lesko (Bruker Nano Surfaces and Metrology, Tucson, Arizona, US) reviews how surface roughness has evolved as a key manufacturing parameter.

Bruker is showcasing two white papers. The first is on surface roughness, which is widely used in industry to validate manufacturing processes and guarantee the quality of products. Subjective judgements of quality, which you can obtain by looking at the surface of a product with your naked eye or feeling it with your finger, have steadily been replaced by unbiased metrics and well-defined formulas. In Advantages of Measuring Surface Roughness with White Light Interferometry, Samuel Lesko (Bruker Nano Surfaces and Metrology, Tucson, Arizona, US) reviews how surface roughness has evolved as a key manufacturing parameter.

Bruker’s other white paper concerns the viscoelastic properties of heterogeneous materials such as polymer composites, blends and multilayers. Making bulk measurements is routine, but it is harder if these materials are composites with nano-sized domains. Fortunately, atomic-force microscopy could provide the answer, as you can discover in Measuring Nanoscale Viscoelastic Properties with AFM-Based Nanoscale DMA by Bede Pittenger and Sergey Osechinskiy (Bruker Nano Surfaces, Santa Barbara, California, US), and Dalia Yablon (SurfaceChar, LLC).

Powerful detectors

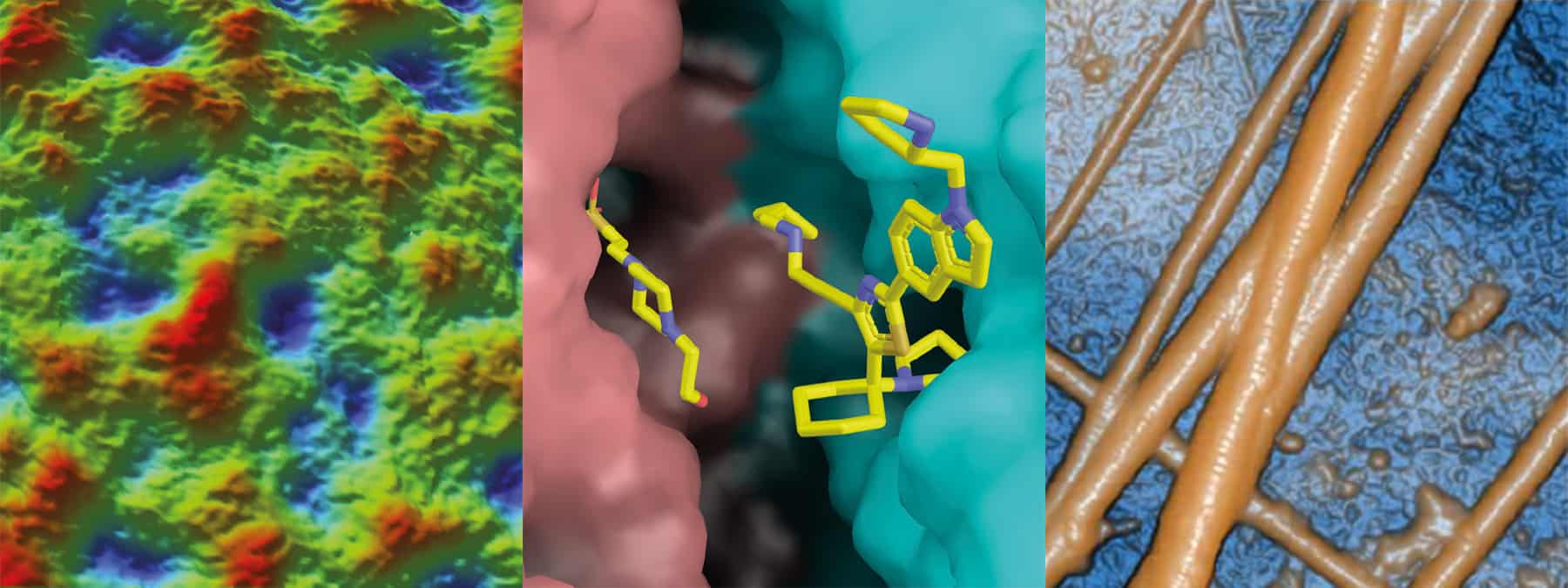

Macromolecular crystallography is the most powerful method for determining the 3D structures of biological macromolecules. Most data are collected at large synchrotron facilities, but these days many crystal structures can be just as easily determined in the lab with detectors from companies such as Dectris. In Macromolecular Crystallography in the Laboratory, Andreas Förster shows how you can get publication-quality structures in the time it takes to send crystals to a synchrotron.

Macromolecular crystallography is the most powerful method for determining the 3D structures of biological macromolecules. Most data are collected at large synchrotron facilities, but these days many crystal structures can be just as easily determined in the lab with detectors from companies such as Dectris. In Macromolecular Crystallography in the Laboratory, Andreas Förster shows how you can get publication-quality structures in the time it takes to send crystals to a synchrotron.

Meanwhile, in PILATUS3 CdTe Detector Technology and its Applications, Tilman Donath describes Dectris’s PILATUS3 CdTe detectors, which are the largest commercially available CdTe detectors for high-energy X-ray detection. He also explains how they are used not just for solving crystal structures, but in geology and materials science, too.

Microscopy matters

Atomic-force microscopes (AFMs), which image materials by probing them with the sharp tip attached to the end of a cantilever, have developed hugely since the first devices were built in the 1980s. But progress has been much more gradual in terms of how fast samples can be studied, with AFM users having to manually place samples on a stage. In Park SmartScan and AutoScript: Improving Operational Throughput and User Productivity, Gerald Pascual, Mina Hong, Byong Kim and Keibock Lee (Park Systems Inc., Santa Clara, California, US) describe the advantages of Park Systems’ large motorized stage, which lets users load large samples and also study small samples one at a time.

If you want to study the structure of biological cells, it is common to “fix” their structure in place before turning to microscopy. But how well do these techniques really conserve the cells’ essential chemical and physical characteristics? In Mechanical Properties of Live and Fixed Cells Measured by Atomic Force Microscopy and Scanning Ion Conductance Microscopy, Jake Kim, Moses Lee and Cathy Lee (Park Systems Corp., Suwon, Korea) show how different microscopy techniques can reveal quantitative differences.

Thanks to their unique electromechanical and electrical properties, ferroelectrics are widely used in industry as actuators, sensors and capacitors. Researchers are also investigating them for use in modern communication technologies such as 5G or solar cells. In Stabilizing the Piezoresponse for Accurate and Crosstalk-free Ferroelectric Domain Characterization via Dual Frequency Resonance Tracking, Ilka Hermes (Park Systems Europe, Mannheim, Germany) and Romain Stomp (Zurich Instruments, Zurich, Switzerland) show how they imaged the ferroelectric domains of a bismuth-ferrite film with resonance-enhanced piezoelectric-force microscopy (PFM) on a Park Systems NX10 AFM with a Zurich Instruments HF2 Lock-In Amplifier.