Welcome to the latest in a new series of sponsored articles showcasing some of the latest white papers and webinars from physics-based businesses around the world

This time we are featuring white papers from Mad City Labs and SAES Group.

When AFM becomes DIY

Atomic force microscopes (AFMs) are versatile tools for characterizing surfaces down to the subnanometre scale. Researchers wanting to, say, map out the optical antennas they’ve inscribed on a chip, or measure the quantum dots they’ve created, can image objects at resolutions down to the picometre level by scanning an AFM over the surface.

Atomic force microscopes (AFMs) are versatile tools for characterizing surfaces down to the subnanometre scale. Researchers wanting to, say, map out the optical antennas they’ve inscribed on a chip, or measure the quantum dots they’ve created, can image objects at resolutions down to the picometre level by scanning an AFM over the surface.

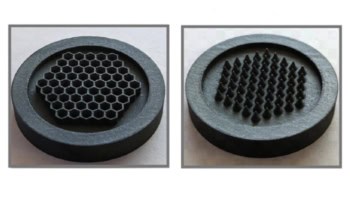

Useful as they are, AFMs aren’t cheap – typically running at $250,000 – which means that they can seem out of reach to many academic scientists, graduate students and researchers at small companies because of their high cost. Fortunately, researchers can build their own AFMs for as little as $30,000 using off-the-shelf components such as nanopositioning stages.

In the Building a Do-it-Yourself Atomic Force Microscope white paper from Mad City Labs, the company’s director of product development James MacKay describes how home-made AFMs can are not just cheap but high-performance too. DIY AFMs allow the researchers to customize the design so that they can do whatever kind of surface testing fits their needs and to tune the performance to suit their requirements.

Cutting carbon contamination

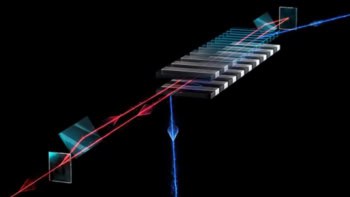

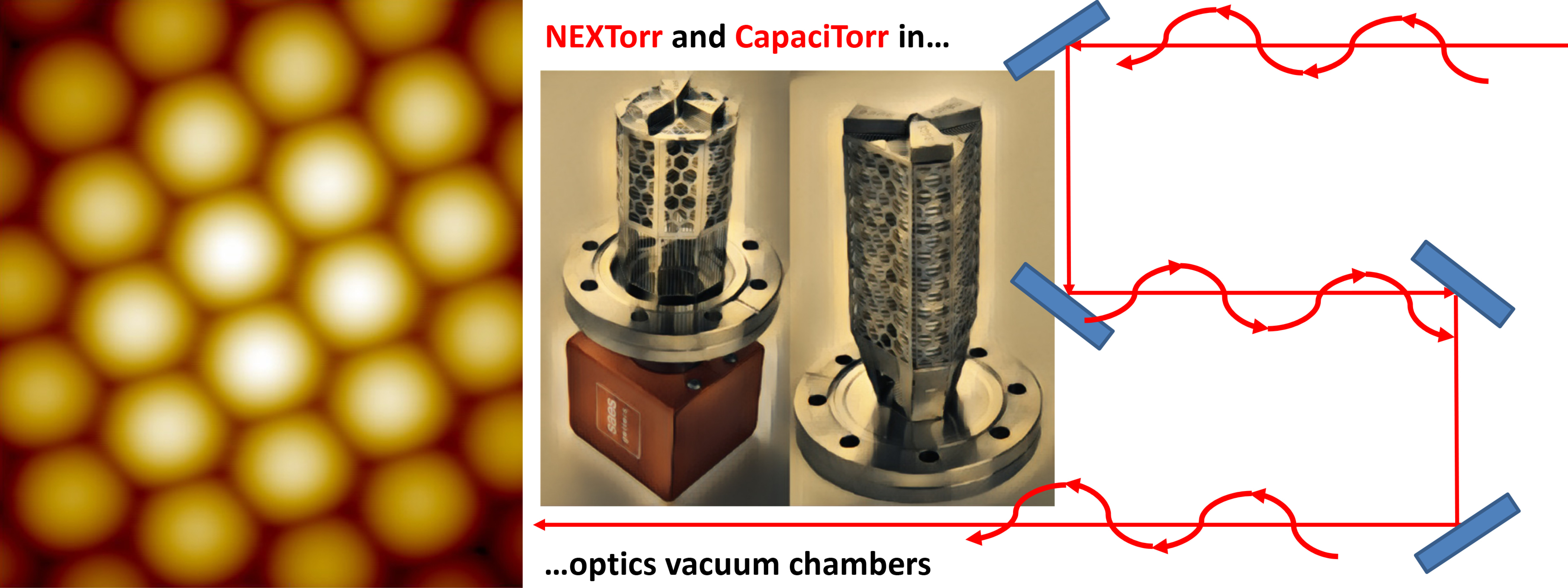

Vacuum engineers and scientists have long known that even if a sample is clean and handled with ultra-high vacuum (UHV) standards, a layer of unwanted carbon will form on the material’s surface after it’s placed in a high-vacuum (HV) or UHV chamber. This also happens for materials in the optics vacuum chambers in particle accelerators and synchrotron X-ray beamlines.

Vacuum engineers and scientists have long known that even if a sample is clean and handled with ultra-high vacuum (UHV) standards, a layer of unwanted carbon will form on the material’s surface after it’s placed in a high-vacuum (HV) or UHV chamber. This also happens for materials in the optics vacuum chambers in particle accelerators and synchrotron X-ray beamlines.

Indeed, X-rays can increase the pressure and yield of carbon contaminants by one to two orders of magnitude, significantly reducing how many X-rays end up downstream at experimental stations. And with next-generation synchrotrons ushering in X-ray brightness increases of two to three orders of magnitude, it is critical to minimize these losses from carbon contamination.

Carbon contamination used to be a show stopper, forcing mirrors to be removed, cleaned and sometimes even replaced. But as staff from SAES Group explain in their new white paper ZAO® Based Non Evaporable Getter Pumps in Optics Vacuum Chambers, the company’s NEXTorr and CapaciTorr pumps can significantly lower the gases that make the carbon residues form in the first place. SAES says that its pumps are much smaller and less invasive than traditional varieties, reducing particle-generation to levels acceptable for synchrotron-radiation studies.