From bone to spider silk, examples of hierarchical structures conferring untold strength to materials abound in nature. While materials scientists have been quick to mimic the approach to enhance mechanical properties, why these structures improve strength is not always well understood. Now, through a series of systematic experiments and atomistic simulations of nanotwinned copper structures, researchers in China and the US have not only shown that gradient structures can increase the strength of these materials, but also reveal the mechanisms behind these enhanced mechanical properties. They believe that the work may allow a more informed approach to the application of gradient structures to strengthen other material systems.

This work provides insights into combining structural gradients at different length scales in order to push forward the strength limit of materials

Crystal twinning refers to the growth of separate crystals with shared lattice points, so that the energy of the interface is lower than a regular grain boundary between arbitrarily oriented crystals. Twin boundaries can affect the crystal’s mechanical properties by blocking dislocations – defects in the crystal lattice arrangement that can move through the crystal. The motion of the twin boundary itself can also alter the stress and strain behaviour of the material. As a result, twin boundaries play a key role in many metallurgical processes, including shock hardening, cold work and quenching.

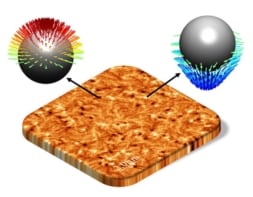

Huajian Gao and Lei Lu and colleagues at the Institute of Metal Research and University of Science and Technology of China in Shenyang, China, and Brown University in the US, used electrodeposition to grow twinned copper samples with crystal widths and heights that gradually increase in size from 29 nm and 2.5 μm to 72 nm and 15.8 μm. While in isolation the twinned crystal component with the smaller grain sizes have greater yield strengths, the total gradient structure was even stronger at 481 ± 15 MPa – comparable with commonly used structural stainless steels. The researchers also noted higher work hardening rates for the gradient structures than the individual components.

Know your strengths

Copper is widely used as a building material so that studies revealing how to improve its strength have intrinsic value. However, Gao, Lu and colleagues were able to take their analysis further, explaining why increasing the structural gradient of twinned structures increases the material’s strength, opening the way for strategically engineering material properties using gradient structures.

Fade boosts lithium battery stability

Transmission electron microscopy analysis revealed bundles of concentrated dislocations in which the researchers identified two modes – one with a recognized role in controlling plastic deformation when the load is perpendicular to the twin boundary, while the other mode is prevalent in thin films, multilayered composites, and highly oriented nanotwinned structures. Atomistic simulations revealed that the way these two modes interact and move adds to the crystal’s strength. These bundles of concentrated dislocations are absent in twinned crystals without the gradient structure.

They conclude that “the gradient nanotwinned strengthening concept proposed in this work provides insights into combining structural gradients at different length scales in order to push forward the strength limit of materials and may be essential to creating the next generation of metals with both high strength and high ductility.”

Full details are reported in Science.