Vacuum technology will be crucial to the success of many large experiments of the future. Joe Herbert outlines some common challenges faced by scientists.

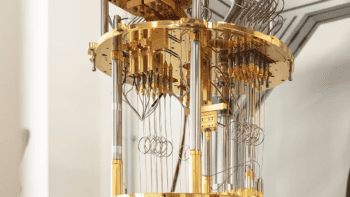

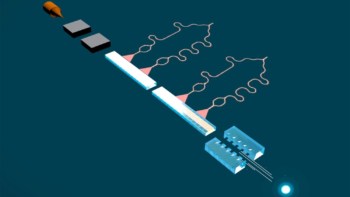

The next generation of big-science experiments, such as CERN’s Large Hadron Collider (LHC) and the International Thermonuclear Experimental Reactor (ITER), will rely on vacuum systems that push the limits of today’s technology in terms of volume and pumping capacity. Others, such as the European X-ray Free Electron Laser (XFEL), will require extremely clean vacuum conditions, while the Laser Interferometer Space Antenna (LISA) will involve launching vacuum systems into space.

The key challenge for a vacuum scientist working on such experiments is how to provide a suitable vacuum environment at reasonable cost. How this is achieved can differ from project to project. This supplement looks at the specific challenges associated with each of these four projects.

While these experiments are all very different, they pose a similar set of challenges to the vacuum scientist. These involve understanding the vacuum requirements of the experiment and how its mechanical design will affect the vacuum system; dealing with the various uncertainties in the operating parameters of vacuum equipment; manufacturing and processing the vacuum components; and finding enough suitably trained people to build and operate the system.

Many early challenges arise because the designers of the experiment – the physicists who will ultimately use the facility as a research tool – may not know what is required of its vacuum systems. Researchers tend to demand the best possible vacuum, even though it may not be necessary. Overspecification leads to unnecessary expenditure, which can be avoided if the vacuum scientist has a good initial understanding of how the experiment will be influenced by the vacuum conditions. Even if the vacuum requirements are well defined, it can be very difficult to calculate to any degree of accuracy the pressure that can be expected at the important positions in a large vacuum system. Many uncertainties must be taken into account and even a small design change can make a large difference to the vacuum conditions. As a result a design will often go through several iterations before a satisfactory vacuum is achieved.

The vacuum scientist must also understand the demands and limitations that will be imposed on the vacuum system by the physical design of the experiment. For example, exotic materials may have been chosen for their mechanical, thermal or electrical properties, even though the vacuum characteristics of the materials are not well known. Measuring the thermal outgassing properties of such materials and finding processing and cleaning recipes to reduce outgassing to a satisfactory level can take a great deal of time. Outgassing is a significant challenge for those building the ITER, for example. The vacuum system for this project must handle gas loads from many thousands of components that are manufactured from specialized materials that have to cope with the harsh environment inside a fusion device.

Particle accelerators, such as the LHC and the XFEL, are usually housed in tunnels where there is little space for vacuum pumps. In addition, the huge lengths of many modern accelerators (nearly 27 km in the case of the LHC) can put severe restrictions on pumping speeds. In the LHC this problem is alleviated by non-evaporable getter (NEG) coatings, which turn the walls of the vacuum chambers into pumps.

Another challenge is the vacuum equipment itself, the performance of which is often not very well defined. For example, the pumping speeds of UHV pumps may only be known for a few gas species. To complicate matters further, similar pumps may achieve different speeds, depending on how an individual pump has been used in the past. Vacuum gauges can also have a major effect on the vacuum – especially at very low pressures – and their stability often leaves something to be desired. It may be that the special requirements of a large facility cannot be met by commercial equipment and new systems must be developed. This usually involves extending existing technologies rather than having to develop something from scratch.

Once the design has been specified, the components must be manufactured and prepared, often using materials and methods at the boundaries, or even beyond the capabilities, of the vacuum industry. Quality assurance is a major challenge, and the project often has to provide the necessary protocols, personnel and equipment. Needless to say, big projects require a lot of detailed design, manufacturing and processing capacity, plus careful record keeping. The final challenge is that of finding enough suitably trained and experienced people who really understand vacuum. It’s not a black art, but it’s not an exact science either.

Download a full digital version of the Vacuum Challenges and Solutions supplement here (PDF, 5MB).