While tiny cameras are now found in just about every mobile phone and laptop, a camera that can fit on the head of a pin and that costs just a few pennies takes miniaturization to a new level. Researchers in the US have developed a micro-camera with no lens, no focusing optics and no moving parts. Just 500 µm across and 10 µm thick, the device could have a number of applications in areas that range from surgery to robotics and imaging.

The micro-camera was developed by postdoctoral associate Patrick Gill and colleagues at Cornell University’s Alyosha Molnar Lab in New York. The camera can resolve images about 20 pixels across, so while it will not be used to obtain high resolution images, its size offers immense scientific and technological possibilities. “It’s not going to be a camera with which people take family portraits, but there are a lot of applications out there that require just a little bit of dim vision,” says Gill.

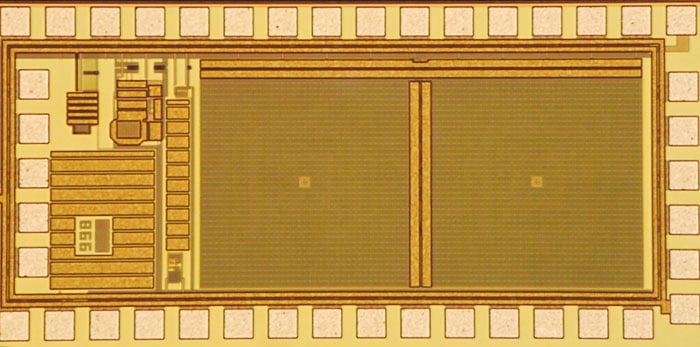

Traditional cameras use focusing optics such as lenses or mirrors, which map incoming light based on its incident angle to a sensor plane made up of photosensitive pixels. But this means that they are bulky, have off-chip optics and require precision manufacturing. To avoid these complications, the Cornell team uses an array of angle sensitive pixels (ASP), each of which is composed of a photodiode under two metal gratings formed using standard semiconductor-processing techniques. Light incident on the upper grating produces an interference pattern that in turn interacts with the second grating. Light is either passed or blocked depending on the alignment of the interference pattern and the second grating. As the alignment is sensitive to changes in the incident angle of the incoming light, the net effect is that the light passed by an ASP depends sinusoidally on the incident angle.

Picket fences

Gill says that a simple explanation of how the light passes through both gratings is the analogy of driving down a street and looking at two aligned fences on the same side of the road. “We have made each pixel of our camera angle sensitive. Consider two picket fences, one behind the other. They have slats and gaps at the same spacing. Looking through the fences, at some angles the gaps of the two fences align, while at other angles the slats of one align with the gaps of the other. The overall effect is that the amount of light coming through the fences is a sinusoidal function of the incident angle. The creation of sinusoidal patterns as a result of two periodic apertures is known as the Moiré effect and that is basically what happens with our gratings too,” explains Gill.

Then, using a Fourier transformation technique commonly used in image processing, each pixel provides one component of the Fourier transform of the image being detected and the various components are then assembled into an image. The researchers call their camera a planar Fourier capture array (PFCA) and while they have only produced an initial prototype of the device, Gill feels that it worked better than expected.

“What is exciting about the PFCA is that it does not require any special manufacturing at all, what we have used is a commercially produced semiconductor. I honestly feel that the uses of the PFCA are limited only by one’s creativity, especially considering how cheap it is,” claims Gill.

In fact, Gill says that he himself became interested in making this micro-camera because as he is a neuroscientist he was looking for ways to introduce an optical system into the brain without causing much damage. “The array could be fashioned into a probe for imaging neurons that have been modified to glow when they are active, which would mean that we could study how the brain’s neurons fire under certain stimuli. And because of its microscopic nature, the damage would be minimal,” says Gill.

Smaller and better

Although the current camera is already microscopic, being produced using a 180 nm CMOS process, Gill believes a 32 nm process could be used, which could mean a factor of two improvement in the resolution. “There was a fair amount of redundancy in our current camera as it is a prototype. Now, after testing the initial design, we know how to improve the resolution and make it more efficient. We could achieve a 40 × 40 pixel resolution,” says Gill. The camera could feature as a component in any cheap electronic system – in devices that detect the angle of the Sun or a micro-robot that requires a simple visual system to navigate.

The research has been accepted for publication in Optics Letters.