Low-loss, highly-reflective “supermirrors” – that is, those that scatter and absorb very few photons – are a key technology for many research fields and are used to make optical resonators for a variety of optics and photonics applications. Until now, however, it has been challenging to make such mirrors for the technologically important mid-infrared (mid-IR) range of light wavelengths between 3‒8 microns.

Researchers at the University of Vienna, Austria; its spin-off Thorlabs Crystalline Solutions; and the US National Institute for Standards and Technology (NIST) have used a new optical coating technology to construct such a mirror from single-crystal gallium arsenide/aluminium gallium arsenide. The mirror has a record-low excess optical loss below 10 parts per million and might find use in applications such as cancer detection, environmental sensors and high-resolution spectroscopy.

Less than 10 in a million photons

The supermirror made by Georg Winkler, Lukas Perner and colleagues is extremely smooth and contains low levels of contaminants. It absorbs and scatters less than 10 in a million photons from its surface. In comparison, the researchers note that an ordinary bathroom mirror loses around 104 times more photons, while even high-quality mirrors used in top-class research lose 10 to 100 times more.

Rather than directly depositing the mirror components onto an optical substrate, as is usually the case when fabricating such structures, the researchers made crystalline coatings using a new epitaxial layer transfer process. In their experiments, they deposited alternating multilayers of high refractive index gallium arsenide (GaAs) and low refractive index ternary aluminium gallium arsenide (Al𝑥Ga1-xAs) alloys. They then transferred these monocrystalline multilayers onto curved silicon optical substrates to make the mirrors. This crystalline coating was developed by Thorlabs Crystalline Solutions.

A new loss mechanism

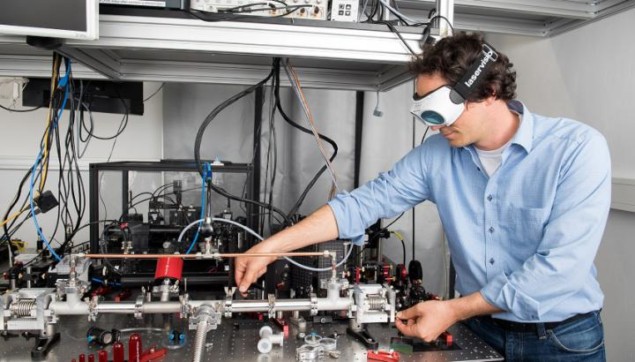

To determine the optical losses of their mirrors, Winkler, Perner and colleagues directed a beam of weak laser light onto them and measured how much light they absorbed. At low levels of light absorption, they made use of a battery of optical measurements, including cavity ring-down and transmittance spectroscopy, as well as direct absorption tests.

During these measurements, they also observed a hitherto unobserved loss mechanism: a very distinct and unexpected change in absorption loss that depends on the polarization of the incident laser light. According to Hartwin Peelaers, a condensed-matter physicist at the University of Kansas, US who also worked on the mirror, this effect could come from the anisotropic elasticity of the crystals when they are strained.

Smooth photonic waveguides keep propagation losses low

The researchers, who report their work in Optica, say they are now developing ways to expand the optical bandwidth of their mirrors and improve their reflectivity even further so that they can be used in different applications. One promising area is high-resolution molecular spectroscopy, which is used to detect minute amounts of substances in gas mixtures – including extremely small concentrations of biomarker molecules in the exhaled breath of patients with early-stage cancer. Other possibilities include precisely detecting leaks of greenhouse gases such as methane from large-scale natural gas production plants and measuring light-matter interactions in fundamental physics research.