Ultrathin solar cells have reached record-breaking efficiency thanks to a novel manufacturing method that introduces specific types of disorder within the cells’ nanocrystalline structure. The low cost, reduced mass and non-toxic nature of this type of cell makes them ideal for integration into cars, rooftops or mobile devices, and the newly streamlined way of manufacturing them paves the way for their large-scale production.

Conventional silicon-based solar cells are highly efficient at generating electricity from sunlight. However, fabricating them is an expensive and energy-consuming process, and the resulting devices are heavy and bulky. Thin-film solar cells are an attractive alternative in some ways, but they often contain elements that are toxic (such as lead or cadmium) or scarce and expensive (such as indium or tellurium). In the mid-2010s, a further alternative emerged when researchers at the Institute of Photonic Sciences (ICFO) in Spain developed a low-cost, non-toxic cell based on AgBiS2 nanocrystals. These nanocrystals can be fabricated into a solar cell just 35 nm thick via a layer-by-layer deposition process, but with an efficiency of around 6% compared to 25% or more for silicon, the material was not yet commercially competitive.

Cation disorder engineering

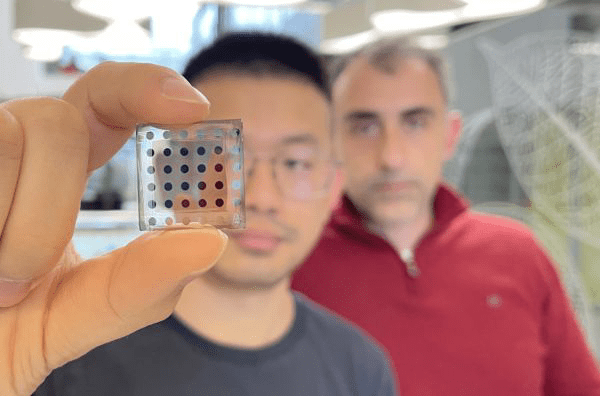

To boost the optical absorbance of AgBiS2-based cells, researchers at the ICFO, together with collaborators from University College and Imperial College in the UK, investigated the impact that disordered positive ions (cations) have on the material’s optoelectronic properties. After finding evidence for inhomogeneities due to Ag- or Bi-rich areas that form within the nanocrystals, they used density functional theory (DFT) calculations to determine the effects of these inhomogeneities. Based on these calculations, they concluded, somewhat counterintuitively, that careful placement of defects in the crystalline lattice – a technique they term “cation disorder engineering” – results in a more homogenous cation distribution because it promotes ionic migration. They then used a process called low-temperature annealing to produce samples of AgBiS2 with the specified characteristics.

When the researchers placed cells made from the optimized material under artificial sunlight, they recorded a power conversion efficiency in excess of 9% – a record for this type of ultrathin solar cell. They also saw absorbance across a wide spectral range, from ultraviolet (400 nm) to infrared (1000 nm). Their device, which they fabricated on glass/indium-tin-oxide and coated with a poly-triaryl-amine solution, is no more than 100 nm thick, making it 10–50 times thinner than current thin-film photovoltaic (PV) technologies and 1000 times thinner than silicon PV.

On a bright path

ICFO physicist Gerasimos Konstantatos, who led the research and co-authored the paper in Nature Photonics describing it, says that the team’s work demonstrates for the first time how changing a material’s atomic ordering affects its optoelectronic properties. This type of materials engineering could also prove useful in other fields, such as catalysis, and Konstantatos notes that the team’s method ticks many boxes for the PV industry, including low cost, scalability, and use of non-toxic elements.

Ultrathin flexible solar cells get an efficiency boost

Alwin Daus, a researcher at RWTH Aachen University in Germany who was not involved in the ICFO study, says that understanding how cation segregation develops and how to control it could prove important for low-cost thin-film solar technologies. He adds that the team’s fabrication process appears ideal for scaling up. However, Daus suggests that the use of ~6 nm diameter nanocrystals could prove a barrier to further improvements in efficiency, as the diffusion length for charge carriers in this type of material is only around 25 nm. Nevertheless, he stresses that the research is important because of high demand within the solar community for stable and environmentally friendly inorganic solar-cell compounds.

Konstantatos says that the team now plans to increase the cells’ open circuit voltage (Voc), which is currently 0.5V. “The Voc is a measure of how much voltage can be drawn from the solar cell and relates to the bandgap of the semiconductor. One should expect to achieve as high as 0.7–0.8V,” he tells Physics World.