Researchers led by Patrick Smith of the University of Sheffield in the UK recently showed that they could print neuronal and other types of biological cells using a piezoelectric ink-jet printer. The neuronal cells printed with the breakthrough technique, originally reported in the IOP journal Biofabrication, have nearly 90% viability and also stimulate neural processes more efficiently and for longer periods than non-printed control samples (Biofabrication 8 015017).

The neural processes generated by the printed cells also proliferate as well as from the control samples, which means there is no discernible difference between these cells and those produced by conventional tissue engineering techniques. The results suggest the team’s precise printing technique could be exploited for lab-on-chip technologies and to fabricate neural networks for fundamental neuroscience studies and applications.

“Ink-jet printing can be used to produce finer neuronal networks than produced by other techniques since the printed cells produce longer neural processes,” Smith explains. “The work in our Biofabrication paper proves that a large number of cell types can be ink-jet printed without any induced side-effects that can denature the cells, and this at higher range of experimental voltages (from 70 V to 230 V) not investigated before.”

The benefits of ink-jet printing

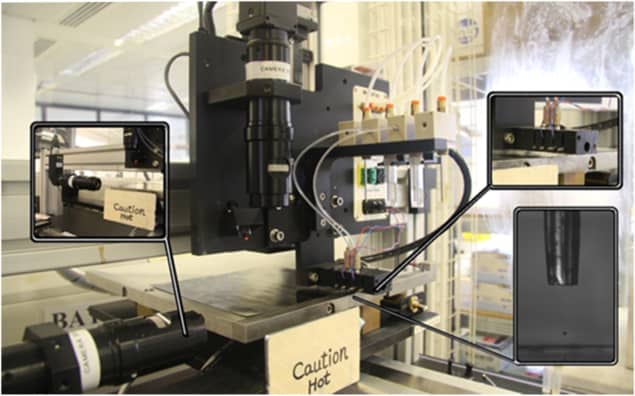

Smith’s lab at Sheffield is interested in applied inkjet printing in many diverse fields – including both biological and non-biological applications, and across industrial and lab-scale science. “The main focus of our work is to find out whether we can use ink-jet printing as a general fabrication route, and if can we add value using ink-jet printing as a means of manufacture,” he told Physics World.

The team’s specializes in so-called reactive ink-jet printing, in which two reactants are deposited to form a product. “For in vitro tissue engineering, for example, we employ this approach to form alginate hydrogels,” Smith continues. “The work we reported in on in Biofabrication fits in well with this new direction of study.”

Smith believes that the technique could directly compete with conventional approaches to tissue engineering, which involve manually seeding cells onto scaffolds. Ink-jet printing offers the advantage that it can produce large numbers of cells quickly, and it also creates reproducibly sized droplets that can be positioned with precision anywhere on a substrate. The important benefit of this new approach is that it can produce undamaged cells that can then proliferate and differentiate after the printing process.

“Since the publication of this study, we have advanced in our research but still need to understand some of the behaviour we observed in printed neuronal cells,” continues Smith. “For example, why do these cells produce neural processes earlier and in greater number than control cells? And why are these neurites longer than those produced by control cells?”

In their study, Smith and colleagues printed neuronal cells from hybrid cells, which are widely used in in vitro studies instead of primary-cultured neurons. Applying their technique to other types of neuronal cells might help them answer these questions. “The next step in our tissue engineering work is to investigate a larger range of cell types and print co-cultures that interact to form biologically relevant constructs,” Smith continues.

The past, present and future of 3D bioprinting

The researchers hope that the interest generated in by their Biofabrication paper will help the team to form new collaborations in the future, both in the tissue engineering world and in other related areas such as controlled crystallization printing and even polymer printing. The team is also studying ink-drying behaviour, printed bioelectronics components, and additive manufacture.

- Read our special collection “Frontiers in biofabrication” to learn more about the latest advances in tissue engineering. This article is one of a series of reports highlighting high-impact research published in the IOP Publishing journal Biofabrication.