An invisibility cloak that is less than five times bigger than the object it conceals has been unveiled by physicists in Denmark and the UK. They say that their device, which they built using semiconductor manufacturing techniques, offers the smallest cloak size relative to cloaked area to date.

First developed in 2006, invisibility cloaks can hide an object from view by bending light around it. The effect is similar to how a star’s immense gravity can warp space–time so that passing light is forced to take a curved path. In invisibility cloaks, however, the path of light is altered not by gravity, but by specially engineered variations in the refractive index of the devices.

Most invisibility cloaks have been able to hide objects the size of just a few microns, but earlier this year a group at the Singapore-MIT Alliance for Research and Technology Centre reported a cloak that could hide objects up to two millimetres big. Meanwhile, Jingjing Zhang and colleagues at the Technical University of Denmark in Lyngby, along with researchers at Imperial College London and the University of Birmingham, reported a cloak that could hide objects on the scale of centimetres. Yet both these cloaks had to be more than 10 times bigger than their cloaking area.

Hiding surface defects

Now Zhang and colleagues have worked out how to reduce this ratio. “In some applications where space is a critical issue, we need to design a cloak as small as possible for a given obstacle,” says Zhang. One of these applications might be in the optoelectronics industry, he adds, which sometimes needs to hide surface defects on microcircuits.

The cloak built by Zhang and colleagues is a carpet cloak, a type of cloak that uses a conducting sheet to flatten – or appear to flatten – the bulge of an object hidden beneath. In previous carpet cloaks, the design has been realized with a complex array of silicon holes or rods, varying in density everywhere to produce an anisotropic structure.

The cloak of Zhang’s group, however, is much simpler: a series of uniform slits (a grating) crafted into silicon using normal semiconductor manufacturing techniques. By changing the amount of silicon relative to air in the grating, the researchers could tune their cloak to be almost as anisotropic as they want. This is crucial to the design because keeping the cloak small relative to the cloaking area requires a lot of anisotropy.

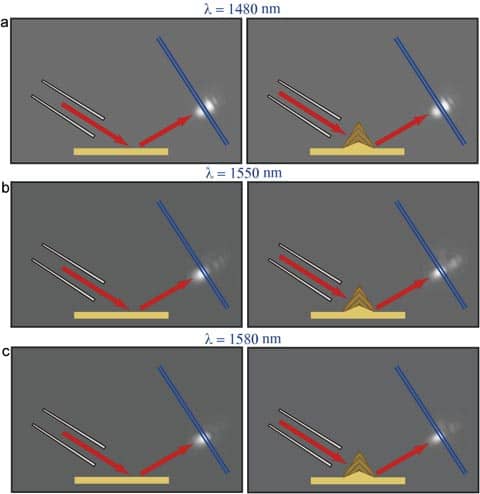

In tests, the cloak could hide a bump in a surface that is the same width as the cloak (10 µm) and around four times shorter (the bump’s height is 1.84 µm and the cloak’s 8 µm). It worked over infrared light wavelengths between 1480 and 1580 nm, although the researchers say that in principle it should work over a broader range.

Drawbacks from very large anisotropy?

Won Park, an engineer specializing in invisibility cloaks at the University of Colorado, says the cloak’s very large anisotropy might have drawbacks. “Some unintended effects such as diffraction may occur at some wavelengths,” he says.

Zhang says her group is now looking to extend the design for bigger objects and for microwaves. “In microwave frequencies…we [may be] able to achieve even bigger object-to-cloak ratios,” she says.

The research is published in Optics Express 19 8625.