When two droplets coalesce on some water-repellent materials, the resulting droplet will jump away from the surface – a process that removes dirt from some biological surfaces such as cicada wings. Now, researchers at Duke University in the US have harnessed this curious effect to create a technique for drawing heat away from “mobile hotspots” on the surfaces of microelectronic devices. The method could therefore be a new way for cooling microprocessor chips, which are becoming increasingly hard to cool as they become smaller and operate at ever higher frequencies.

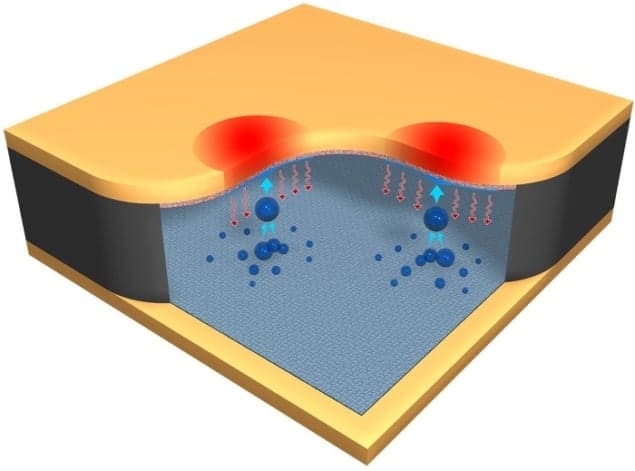

The system developed by Duke’s Chuan-Hua Chen and colleagues consists of a sealed, disc-shaped chamber that is about 2 mm thick and contains water vapour. One inside surface of the chamber is made from a superhydrophilic (highly water-retaining) material covered with a water-absorbing wick. The opposite surface is superhydrophobic (highly water-repelling), on which water forms mobile droplets.

Condensing droplets

The superhydrophilic side is placed next to the surface to be cooled (see figure and video), which causes heat from a hot spot to be transferred to it. Water on the heated superhydrophilic surface therefore evaporates into the chamber, cooling the surface and hot spot. Most of this vapour travels across the 2 mm gap and condenses on the opposite superhydrophobic surface, where it forms droplets.

These droplets then rapidly coalesce, jump away from the surface and end up right back at the hot spot on the opposite superhydrophilic surface. The jumping droplets therefore replenish the supply of cooling water to the hot spot. If the hot spot moves, the evaporation-jumping cycle will simply occur at the new location.

Mobile hot spots occur in different places on a chip at different times, depending on what tasks the chip is performing. It can be difficult to predict where and when these hot spots will occur, and this transient nature makes mobile hot spots difficult to deal with using simple, low-cost passive cooling. Instead, more complicated and costly active cooling systems must be used. Chen’s team believes its device could solve this problem.

Comparable to copper

While the Duke technique demonstrates the principle of using jumping drops for cooling, the team now needs to find suitable surface materials that will function for long times when subjected to a high-temperature vapour. “It has taken us a few years to work the system to a point where it’s at least comparable to a copper heat spreader, the most popular cooling solution,” says Chen. “But now, for the first time, I see a pathway to beating the industry standard.”

The new cooling device is described in Applied Physics Letters.