Metallic glasses are promising materials for structural engineering, but their poor ductility makes them brittle, limiting their applications. Researchers in China have now shown that these glasses can be made much softer by reducing their size down to the microscale.

As their name implies, metallic glasses have the properties of both metals and glasses – they contain metallic bonds and are thus conducting, but their atoms are disordered like in a glass. These metastable materials are produced by rapid quenching from the liquid state and their physical properties depend on how they have been processed. They can be made more plastic to some extent by applying stress or high temperatures, but the effect – which is related to structural disordering in the material – is limited.

A marked rejuvenation effect

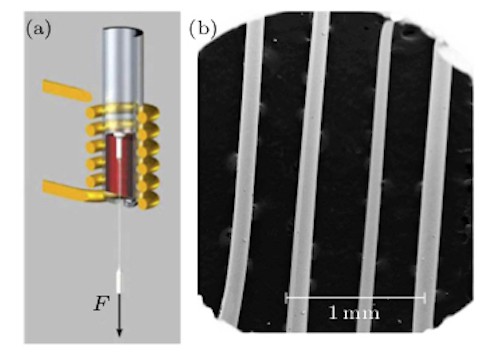

Researchers led by Bao-An Sun and Hai-Yang Bai of the Institute of Physics at the Chinese Academy of Sciences in Beijing are now reporting on a marked “rejuvenation”, or softening, of metallic glasses that have been drawn while still hot into micron-sized wires. Compared to their bulk counterparts, the modulus and hardness of these wires are much lower, decreasing by 26% and 17%, respectively.

“Such pronounced rejuvenation is unusual for metallic glasses,” explains Sun, “with previous studies reporting on only a few percent decrease in modulus and hardness.”

Higher free volume content

According to the researchers, the hot-drawn micron-sized metallic glass wires become softer and more plastic for two reasons. First, the severe thermomechanical shearing involved in the hot-drawing process provides the material with energy, thereby increasing its “free volume” (a measure of the spacing between molecules). Second, the material’s subsequent rapid cooling “freezes” this induced free volume in place. As the size of the wires decreases, more free volume is induced, and this, coupled with a higher cooling rate, produces more pronounced rejuvenation.

Liquid phase-change material behaves like water

“Our results clearly suggest that we can significantly rejuvenate metallic glasses through a proper combination of temperature, shear stress and size reduction,” Sun tells Physics World. “Our technique thus provides us with a new way of tuning and designing the structure and properties of these materials.”

The researchers, who report their work in Chinese Physics Letters, say they will now focus on controlling the rejuvenation of the metallic glass wires in a more quantitative manner – by determining the exact role of temperature, stress and size reduction in the process they have developed