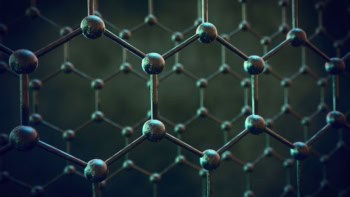

Physicists in the US have developed a technique for soldering nano-sized objects without contaminating them. The technique could be used to make clean electrical contacts between advanced structures such as graphene in the making of tiny transistors and nanomachines.

Most researchers make electrical contacts on nanostructures using electron beam lithography — an expensive and time-consuming technique that involves scanning a beam of electrons across a surface masked with a polymer “resist”. Importantly, the resists and solvents used in the process leave residues that contaminate samples, sometimes adversely affecting their final properties.

No mess

Now, Alex Zettl and Caglar Girit at the University of California at Berkeley have come up with a cheap, quick “nanosoldering” technique that overcomes these problems. They begin by placing the sample to be contacted on one side of a holder with a small bead of indium — a metal known to adhere to many surfaces — on the other. While watching through a microscope, the researchers heat the holder above indium’s melting point and dip a room-temperature tungsten tip into the molten indium bead using a mechanical “micromanipulator” to slowly pull out a spike of solder.

In the final step, they use the micromanipulator to position the solder spike over the sample and quickly raise the holder, which fuses the solder spike onto the sample as the two come into contact. Once contact is made, the sample heater is turned off and the contacts solidify (Appl. Phys. Lett. 91 193512).

Low resistance

Zettl and Girit have already used nanosoldering to contact graphene. This material, which comprises a single sheet of graphite, has interested scientists because it can be both a semiconductor and a very good electrical conductor, making it useful for certain nanoscale electronic devices. After soldering nine different graphene devices, the researchers found that the resistance over the contacts varied from 190 to 1700 Ω with a mean value of 680 Ω, comparable to the best electron-lithography contacts.

According to the researchers, the new technique can be used to contact nanotubes and nanowires as well as graphene. Moreover, they say it could open the way to building nanomachines piece-by-piece by fusing small components together, rather than using complicated chemical methods.