Necessity, the saying goes, is the mother of invention. In the case of Liquid Instruments, a start-up venture with its origins in big astronomy and space-science projects at the Australian National University (ANU) in Canberra and NASA’s Jet Propulsion Laboratory (JPL) in California, it seems necessity is also the mother of innovation, entrepreneurship and a singular vision to rewrite the rules of the scientific test and measurement market.

Daniel Shaddock, CEO of Liquid Instruments and a part-time physics professor at ANU, spent the first 18 years of his research career (he’s still only 43), working on big-science collaborations such as the LIGO gravitational-wave experiment, GRACE Follow-On – a satellite mission to track changes in the Earth’s water systems – and a planned space-based gravitational-wave observatory called LISA.

Shaddock and colleagues were driven by a core philosophy to simplify the complex – specifically with regard to the hardware and advanced instrumentation that underpin these multicentre and multidisciplinary science and engineering collaborations. Or as he puts it: “What if we try to reduce how much hardware we have? What if we try to reduce the requirements of that hardware and the complexity of that hardware? And what if we push all of that complexity into the digital-signal-processing domain?”

In 2014, however, that focus on frontier scientific endeavour unexpectedly hit a wall, when funding cuts to Australian space science left Shaddock faced with the break-up of his international team of PhD students and postdoctoral researchers.

The team, however, was not for breaking up, and instead posed the collective question: what if we start a company and give it a go? The answer to that question is Liquid Instruments and a flagship product offering called Moku:Lab, a software-configurable hardware platform for precision test and measurement and advanced digital signal processing.

“The company sort of began out of necessity and had 12 founders – basically all of the students and postdocs that I needed to build the Moku:Lab product,” Shaddock explains. “A lot of our advantage stemmed from the great support we got from ANU. We didn’t have money to run full-time, so we put the team on half-time research appointments.”

That turned out to be a win-win: scientists who didn’t go into physics to become entrepreneurs got to do their big-science experiments half of the time, while the rest of their time was spent on the faster-paced commercialization work. “That was a lovely balance – and a fun time as well as a scary time,” Shaddock adds.

Thinking big

Fast forward to 2019, and earlier this month Liquid Instruments took a significant step in its ongoing evolution after closing an $8.16 million Series A funding round led by US-based Anzu Partners and follow-on investor ANU Connect Ventures in Australia. That backing builds on an impressive 2018, when Liquid Instruments clocked more than $1 million in Moku:Lab sales to 22 countries.

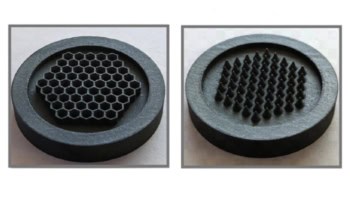

The latest investment will in turn help to accelerate development of Moku:Lab, which currently integrates 12 precision test and measurement instruments – including an oscilloscope, lock-in amplifier and phase meter, among others – into a single, compact hardware device using a field-programmable gate array (FPGA)-based software-reconfigurable platform. (An FPGA is a special type of semiconductor chip that can quickly be reconfigured for different purposes using software.)

To replicate all that Moku:Lab can deliver would require tens of thousands of dollars in separate equipment purchases and significantly more lab space to house it all

Daniel Shaddock, Liquid Instruments

Core technology aside, the unique selling point of Moku:Lab is workflow convergence. In other words, the opportunity for scientists and engineers – whether in a research, corporate R&D or undergraduate education setting – to simplify and declutter versus the conventional approach to test and measurement with its many separate (and costly) pieces of specialist kit and the sprawling laboratory real-estate needed to house it all.

“Moku:Lab represents a fundamental transition in the test and measurement equipment market,” claims Shaddock. “Instead of buying an oscilloscope to measure signals in the time domain, a spectrum analyser to measure them in the frequency domain, and a waveform generator to output signals, we’ve put all that functionality and more into very-high-speed digital signal processing. We have replaced multiple instruments with a single high-precision device.”

What’s more, by pushing complexity and functionality out of the hardware and into the FPGA/digital-signal-processing space, Moku:Lab comes with built-in scalability and a neat upgrade model that allows users to build an enhanced and growing menu of test capabilities over time.

“When we first launched Moku:Lab a couple of years ago, there were three instruments in it – an oscilloscope, spectrum analyser and waveform generator,” says Shaddock. “Since then, every few months when the team in the lab have finished a new instrument – for example, the Bode analyser or digital filter box – we have been able to push that functionality out to customers as a software update. That’s a far more flexible way of doing things when compared to conventional, analogue instruments.”

Another big driver for Shaddock and his team is to take best practice from modern user-interface design and apply it to the test and measurement industry. Moku:Lab is controlled through Liquid Instruments’ iPad app or via custom LabVIEW, Python and MATLAB application programming interfaces, with a Windows version in the works.

“We are focused on improving user workflow,” says Shaddock. “With Moku:Lab, users can save data to the cloud, analyse results right from the device, and use the intuitive user-interface to help them complete tasks much faster than with legacy instruments.”

The view from the lab

Research customers, for their part, seem convinced about the Moku:Lab model and its potential to reset their workflows – and outcomes – for the better.

Bruce Marsh, an applied physicist in the engineering department at the CERN/ISOLDE Radioactive Ion Beam facility in Geneva, is a case in point. Marsh and his colleagues have had a Moku:Lab in their lab for over a year and mainly use it for monitoring and optimizing laser-pulse timing.

“Our lab has many nanosecond pulsed lasers that all need to be temporally overlapped,” he explains. “It’s great to be able to just walk around the lab with the iPad and optimize parameters instead of our previous approach of shouting instructions across the room at each other.”

He’s also motivated by the built-in scalability of the Moku:Lab platform – and in his specific case the recent addition of a laser lock-box instrument. “This is something that we requested when we first bought the Moku:Lab,” says Marsh. “The intuitive interface to configure the lock-in amplifier settings and the built-in oscilloscope preview make it so much more user-friendly than traditional laboratory devices. This means that you can concentrate on getting the optimal settings, rather than trying to figure out how to navigate the menu of the device.”

- Liquid Instruments will be exhibiting at SPIE BIOS 2019 (booth #8259) and SPIE Photonics West 2019 (booth #5664) from 2-7 February at the Moscone Center in San Francisco. See below for a video demo from the show.

Building Moku:Lab momentum in the US

Danielle Wuchenich, co-founder and chief strategy officer at Liquid Instruments, is faced with a challenge that will sound all-too-familiar to many technology start-ups: laying the tracks while the train is running.

More often than not, this sees Wuchenich juggling day-to-day operational priorities – sales development, staff recruitment and existing customer relationships – while building a longer-term view of the market opportunity for Moku:Lab in the US.

“Many of our existing customers are here in the US – professional scientists and engineers working in university research, national labs and corporate R&D,” says Wuchenich, who heads up the firm’s US strategy, operations and partnerships from a base in Palo Alto, California.

While her near-term focus is hiring and staffing a local sales and support team to grow visibility and market penetration for Moku:Lab in the US, Wuchenich is also sizing up what could turn out to be a significant growth market through 2020/21 – and not just in the US. “We want to diversify and customize Moku:Lab to deliver a product line targeted specifically for physics and engineering undergraduate teaching labs,” she explains.

For now, though, there’s the upcoming Photonics West/BIOS 2019 event, the annual international gathering of optical scientists, engineers and technology vendors in San Francisco. “Since we started Liquid Instruments, Photonics West has been our big show – this is our fourth time as an exhibitor,” says Wuchenich. “It’s a combination of customer acquisition, catching up with existing customers, as well as looking for proactive distribution partners who can help us reach new markets and territories.”

Photonics West also sees the official launch of the laser lock-box, the latest instrument addition to the Moku:Lab platform (see main article). “This is the first instrument that we’ve developed specifically for the optics and photonics community,” Wuchenich adds, “so we’re very interested to see what the response will be on the exhibition booth.”