Martin Weides talks to Matin Durrani about his new role as consultant technical director to Oxford Instruments NanoScience, a UK-based firm that builds equipment serving applications ranging from quantum science to nanotechnology

What are your main responsibilities at Oxford Instruments NanoScience?

My role there is to push the company’s technology, advise on new developments in techniques such as dilution refrigeration, and to identify opportunities in the field. The company has products serving both quantum computing and the physical sciences, including a wide range of cryostats as well as dilution refrigerators that can cool samples to a few millikelvin. They all have a range of options for studying samples with magnets or lasers.

You’re combining your new role with your existing position at the University of Glasgow, where you’ve been since 2018. What’s the focus of your research group there?

My team focuses on superconductor-based quantum circuits, developing the cryogenic hardware, the nanoelectronic chips and the electronics needed for quantum computers. Our research therefore covers everything from materials science and device fabrication to circuit integration. We collaborate with other researchers, with start-ups, and with small and medium-sized enterprises (SMEs) both in the UK and internationally. For example, we’re involved in the Quantum Computing and Simulation Hub hosted by the University of Oxford, and have two projects with industrial partners, funded by Innovate UK.

Can you give examples of your work?

We’ve recently been investigating the long-term stability of individual “fixed-frequency” qubits, similar to those that Google and IBM are using for their quantum processors. It turns out that these quantum circuits aren’t very stable for more than a few hours because their coherence times and resonance frequency are affected by tiny, fluctuating surface defects. Finding ways to reduce these microscopic states is a big challenge, but we’ve got some ideas to try. Another recent project has led to a cleaner, wafer-scale process for making tunnel junctions, which are the key component of superconducting quantum circuits. We’ve also been studying the thermal noise introduced by the coaxial wiring to the quantum-computing stage and finding ways to scale up quantum processors.

What other expertise do you hope to bring to the new consultancy role?

Having worked with cryogenic quantum circuits and technologies for almost two decades, I’ve seen them grow dramatically during that time. It’s involved a fascinating mix of electronics, optics, photonics and, of course, cryogenics. There are lots of exciting new applications ranging from dark-matter detectors and single-photon cameras to implementations in quantum metrology, quantum simulation and quantum computing. That progress involves advances in materials science, integration concepts and chip design, underpinned also by improvements to theoretical models and to supporting hardware, such as electronics and cryogenics. My appointment will further support the momentum Oxford Instruments NanoScience is building in quantum computing and materials science to ensure the firm stays at the forefront of the innovation.

Quantum circuits and technologies involve a fascinating mix of electronics, optics, photonics and cryogenics

What’s the most challenging requirement from customers working with quantum tech? Price, size, low noise or cooling ability?

I think it’s all of those things. Keeping the chips well isolated from infrared radiation running down the coaxial lines or from outside the sample package is a big challenge, as is keeping it cold when pulsing more and more qubits simultaneously. When it comes to scaling up devices, then the integration, filtering and thermalization of high-density coax lines with high signal purity is paramount to achieve quantum error correction or increase the quantum volume of a quantum processor.

The quantum scale-up demand goes beyond having more wiring and a bigger fridge, though. Another challenge is the shift from research being funded by government grants to it being funded by companies earning money from selling products in the area.

In such a new market like quantum tech, how do you work out what customers need?

First, we’re close to our customers in both industry and academia. We have a wide range of activities such as sponsoring scientific meetings and conferences, hosting virtual symposium and publishing technical white papers. We also have the Nicholas Kurti Science Prize for Europe, which promotes and recognizes innovative work of early-career scientists in Europe who work with low temperatures and/or use high magnetic fields. And don’t forget that the company does a lot of research and development (R&D) itself – last year investing £26.8m, or 8.4% of turnover, on it. That focus has been kept up over the past 18 months, despite the global pandemic. It’s critical for the business.

Is it hard to develop the right products in a field where research is moving so fast?

Yes, but it’s exciting as well. In quantum computing, for example, we’ve seen massive improvements over the last five years in the number of superconducting qubits you can squeeze on a chip. But other hardware platforms, based on semiconductors, are catching up fast. We’re also seeing traditional, room-temperature-based quantum-computing platforms, such as photonic chips or ion traps, going cryogenic to boost their gate fidelities.

Quantum computing and qubit scale-up applications with Proteox from Oxford Instruments

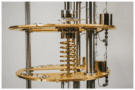

Then there’s the development of more and more hybrid approaches, such as super- and semiconducting circuits with optical faces or “cryoCMOS” control chips near the qubit processor. To serve this evolving market, the new Proteox family of dilution refrigerators provides customers with extra space to install components and other equipment, while also letting them mount samples more easily to operate devices with lots of qubits.

I’d say that the advent of cryogen-free dilution refrigerators 10–15 years ago has allowed researchers to fully focus on the science and technology of quantum computing circuits. What’s more, larger and more powerful cryostats have recently been developed that can host quantum processors with more than 50 qubits, hundreds of coaxial lines and plenty of passive and active microwave components. That’s a dramatic improvement – previous cryostats had a sample volume barely the size of a teacup, whereas now they provide much more space.