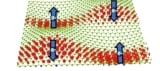

Researchers from the Institute of Physics of the Chinese Academy of Sciences have produced the first two-dimensional (2D) sheets of metal. At just angstroms thick, these metal sheets could be an ideal system for studying the fundamental physics of the quantum Hall effect, 2D superfluidity and superconductivity, topological phase transitions and other phenomena that feature tight quantum confinement. They might also be used to make novel electronic devices such as ultrathin low-power transistors, high-frequency devices and transparent displays.

Since the discovery of graphene – a 2D sheet of carbon just one atom thick – in 2004, hundreds of other 2D materials have been fabricated and studied. In most of these, layers of covalently-bonded atoms are separated by gaps. The presence of these gaps mean that neighbouring layers are held together only by weak van der Waals (vdW) interactions, making it relatively easy to “shave off” single layers to make 2D sheets.

Making atomically thin metals would expand this class of technologically important structures. However, because each atom in a metal is strongly bonded to surrounding atoms in all directions, thinning metal sheets to this degree has proved difficult. Indeed, many researchers thought it might be impossible.

Melting and squeezing pure metals

The technique developed by Guangyu Zhang, Luojun Du and colleagues involves heating powders of pure metals between two monolayer-MoS2/sapphire vdW anvils. The team used MoS2/sapphire because both materials are atomically flat and lack dangling bonds that could react with the metals. They also have high Young’s moduli, of 430 GPa and 300 GPa respectively, meaning they can withstand extremely high pressures.

Once the metal powders melted into a droplet, the researchers applied a pressure of 200 MPa. They then continued this “vdW squeezing” until the opposite sides of the anvils cooled to room temperature and 2D sheets of metal formed.

The team produced five atomically thin 2D metals using this technique. The thinnest, at around 5.8 Å, was tin, followed by bismuth (~6.3 Å), lead (~7.5 Å), indium (~8.4 Å) and gallium (~9.2 Å).

“Arduous explorations”

Zhang, Du and colleagues started this project around 10 years ago after they decided it would be interesting to work on 2D materials other than graphene and its layered vdW cousins. At first, they had little success. “Since 2015, we tried out a host of techniques, including using a hammer to thin a metal foil – a technique that we borrowed from gold foil production processes – all to no avail,” Du recalls. “We were not even able to make micron-thick foils using these techniques.”

Undulations could replace twists in 2D materials

After 10 years of what Du calls “arduous explorations”, the team finally moved a crucial step forward by developing the vdW squeezing method.

Writing in Nature, the researchers say that the five 2D metals they’ve realized so far are just the “tip of the iceberg” for their method. They now intend to increase this number. “In terms of novel properties, there is still a knowledge gap in the emerging electrical, optical, magnetic properties of 2D metals, so it would be nice to see how these materials behave physically as compared to their bulk counterparts thanks to 2D confinement effects,” says Zhang. “We would also like to investigate to what extent such 2D metals could be used for specific applications in various technological fields.”