An alloy that undergoes a reversible temperature change of 31.5 K when squeezed has been created by physicists in China, Spain and the US. Materials that exhibit such a “colossal elastocaloric effect” could be used to create new types of highly-efficient refrigeration systems.

Refrigeration plays an important role in a wide range of human activity and keeping people and things cool consumes huge amounts of energy. Researchers are therefore very keen on developing alternatives to the relatively inefficient (about 20%) vapour compression systems that are in widespread use today. These refrigerators are also ripe for replacement because they tend to be noisy and use gases that can be dangerous or detrimental to the environment.

An alternative approach involves using “caloric” materials, which release heat when subjected to an external stimulus such as an applied magnetic or electric field or a compressive force. When the stimulus is removed, the material will absorb heat, thus cooling its surroundings. By applying and removing the stimulus on a carefully chosen timescale, a refrigeration cycle can be created.

In the past, much of the focus had been on creating refrigerators that use magnetocaloric materials. However, this has not led to the development of commercial devices for widespread use.

Low-cost option

Now, researchers are turning their attention to the elastocaloric effect, which involves squeezing solid crystalline (or polycrystalline) materials. Elastocaloric materials are attractive because they tend to have larger reversible temperature changes than magnetocalorics. They also tend to be less expensive – comprising alloys of metals rather than more pricy rare-earth magnets.

Plastic refrigerant could lead to more environmentally friendly cooling systems

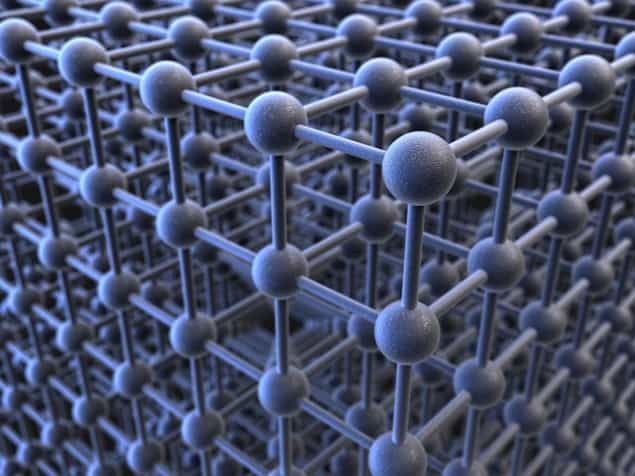

The elastocaloric effect occurs when a material undergoes a transition in its crystal structure when it is squeezed. This latest research was done by Daoyong Cong and colleagues at the University of Science and Technology in Beijing, the University of Barcelona and Argonne National Laboratory and focussed on an alloy of nickel, manganese and titanium (with a tiny amount of boron). The uncompressed material has an austenite crystal structure, that is converted to a martensite crystal structure by about 500 MPa of squeezing. This results in a change of temperature of 31.5 K. This is more than double the temperature change in the best magnetocaloric material and about 26% greater than the previous best elastocaloric – which is a nickel-manganese alloy.

The team used several criteria to select their elastocaloric material from a group of alloys containing nickel, manganese and one other metal. A material must undergo a large (about 2%) change in volume during the structural phase transition and the material must have mechanical properties that are compatible with being repeatedly squeezed and expanded. Furthermore, the material should be polycrystalline so that it can be easily and cheaply manufactured in bulk.

Writing in Physical Review Letters, the team describes their research as a “significant step forward towards large-scale elastocaloric refrigeration applications”. Furthermore, they say that their selection criteria could be used to find other materials that exhibit the colossal elastocaloric effect.